Faba beans, Direct Heading vs. Windrowing

| Date: 21 Sep 2010

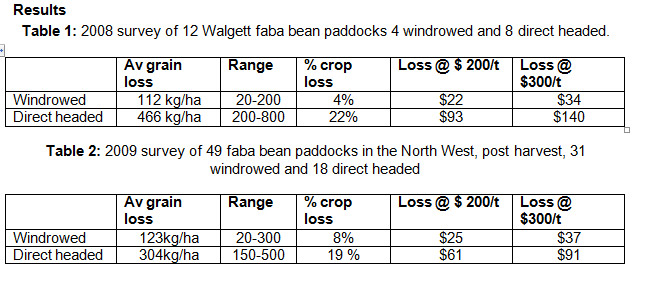

Agronomy chiefly focus’s on production improvements through new varieties, fertility, and disease management, but often stops at crop maturity. Two simple harvest surveys over 2 years, has shown that agronomists should also pay close attention to how and when faba bean crops are harvested. In 2008 comparing the harvest methods of faba beans in Walgett showed that yield could be improved on average by 18% if farmers windrowed their beans. This was highly relevant when faba bean prices were over $300/t that year. In 2009 a more thorough survey comparing direct heading and windrowing of faba beans in northern NSW was conducted to investigate this issue.

In Walgett a few farmers for several years have been successfully windrowing faba beans and significantly improving their gross margins. Windrowing is not new, there has been a good “Pulse Point “produced by NSW Agriculture on the subject, but until 2009, direct heading had been the main method of harvesting for 95% crop. In mixed operations with sheep, having some harvest loss was never an issue for faba beans can be easily utilised by foraging sheep. The harvest loss of beans is rarely quantified by farmers or agronomists, but both growers and agronomist often wonder why some apparently good crops yield poorly. The paddock surveys show that some poor yields are a result of poor harvest techniques.

Survey Method

The numbers of faba beans left behind after harvest were counted. 10 counts in a 0.25m quadrant were made across a paddock, both in the header trail and also between the trails. Beans in pods were rubbed out and counted. An average seed weight was estimated based on the seasonal conditions so that the loss could be presented on a weight/ha basis. General observations of the paddock were also made and in most cases the grower or consultant agronomist was questioned to gain insights into the harvest operation

Discussion

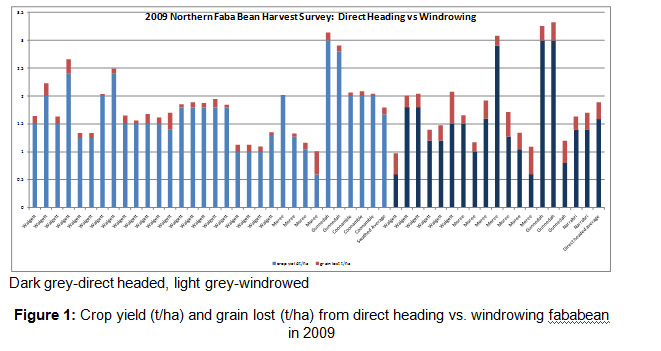

The results from the survey were clear that on average windrowing has less harvest losses than direct heading. Only 2 direct headed crops had losses larger than the average loss of the direct headed crops in 2009. The extra cost of windrowing is approximately $30-40 per ha therefore from the 2009 figures this would suggest that the profitability of windrowing can be marginal, when bean prices are as low as $200/t. In the 2009 survey, 15% of the windrowed crops did not save more than more than $30/ha and 40% of the windrowed crops did not save more than $40/ha than direct heading. Therefore in 2009, 60% of the windrowed crops were clearly more profitable than if they were direct headed even when bean prices were as low as $200/t.

It should be noted that 2009 saw more faba bean crops windrowed than ever before, so for the majority of growers and contractors this was the first time they had harvested beans this way. Therefore the overall quality of windrowing may have been less than it’s potential due to lack of experience. In 2008 windrowing was 18% better than direct heading, but in 2009 windrowing was only 11% better. Losses from windrows placed in wheel tracks were seen in many paddocks using controlled traffic, as seen in the photo. Secondly in 2009 many of the windrowed beans were lodged due to strong winds, if these crops were direct headed the losses would have been much higher. It could be assumed that the average losses from direct headed crops were possibly less than they would have been if farmer practice was the same as 2008. These back ground factors must be considered when looking at table 1 and 2 and it should also be noted that many beans have been sold for more than $200/t on farm in 2009.

Another economic factor to consider is, that if windrowing only pays for the operation itself when grain prices are low, this still has a significant economic benefit to the rural economy through income injection. Beans left on the ground are dead revenue unless they can at least be utilized by grazing stock.

There are growers who direct head and achieve harvest results similar to that of windrowing; this was seen in both 2008 and 2009. In those years, no direct heading loss was ever less than the average loss from windrowing. However 15 % of direct headed crops in 2009 achieved losses less than 200kg/ha which is a good result considering the average loss from windrowing was 120kg/ha. For some growers they will always direct head and will only consider windrowing when lodging is severe or some other environmental factor arises.

The reasons for windrowing are not just for reducing harvest loss! Growers mentioned how windrowing allowed for a timely harvest of their beans, so that they could then concentrate on harvesting cereals. Few growers have talked positively about desiccation as a reliable option. 2008 was a difficult faba bean harvest because the crop would not dry down due to late rain and this was part of the reason Walgett growers switched to windrowing beans in 2009.

The best way to windrow

In the 31 windrowed crops a variety of windrowing equipment and configurations were used. Some of the best jobs done were achieved by using a standard draper front with a panel removed as in the photo. These varied from 30-40 ft wide. Some of the best results were achieved by operations done by the growers’ own staff and equipment or a contractor whom they have worked with for many years. Some of the poorer jobs were done by self propelled swathers, not because they couldn’t do a good job, but because they travelled too fast or were inexperienced with beans. The ideal system for control traffic was a 12 m swather on 3 m wheel spacing allowing the windrow to be placed in-between the wheel tracks, however this does not suit 2 m wheel tract systems.

Factors that influence harvest losses from paddock observations and discussions.

Windrowing

• Timing: Too late and pods are too brittle

• Size of windrow: have enough material to feed into the pick up front. Consider biomass of crop and width of swath.

• Skill and speed of swather: Adjust speed to the job. Are you paying your contractor enough to do a good job?

• Placement of windrow: Windrows in wheel tracks did not get picked up consistently

• Paddock levelling: Hollows and ridges in unlevelled paddocks reduced ability to pick up windrow and to place crop in windrow.

With harvesting of all legumes, growers need a good “relationship” with their contractor to get the best job done, interpersonal/financial. The best jobs “appeared” to be done by grower owned headers or a contractor who regularly worked for the grower.

Direct headed.

• Loss at header front

• Lodged crops cannot be completely recovered

• Green plants with mature pods

• Too late and some beans have already fallen on the ground

Summary: Pros and Cons of windrowing.

Pros: Windrowing

• Able to time the harvest, beans are finished before cereals

• More effective than desiccating

• Lodged crops can be salvaged effectively

• Significantly less losses than direct heading when done properly

• Can be more profitable

Cons: Windrowing

• Windrowing is another production cost

• Losses can be just as high as direct heading if not done effectively

• Sample can have more dirt in it

• Risk of windrow weather damage due to excessive rain. In 2009 windrows took over 10 days to dry down

• Timing must be right for quality beans

• Not an option if crop biomass is too small

Conclusions

Windrowing does achieve fewer losses than direct heading, but the windrowing operation must be done timely and properly with risks weighed up. In some years or situations it will not be more profitable to windrow, especially when faba bean prices are low.

Acknowledgements

Thank you to District Agronomists: Rebecca Byrnes, Rowan Brill, Bill Manning and Tim Burley (Industry and Investment) and Walgett consultant agronomists Simon Logan and Greg Rummery for collecting some of the paddock data for the 2009 survey. Thank you to the growers who allowed us to count their fallen beans and to ask them questions and to David Ricardo for the use of some of his pictures.

Contact details

Myles Parker

Department of Industry and Investment, Primary Industries

PO Box 249, Walgett NSW, 2832

02 68280126, o419 217 553

026828 2274

Myles.parker@industry.nsw.gov.au

Was this page helpful?

YOUR FEEDBACK