To windrow or not to windrow in 2016? This is the question, but if so, when?

Author: Maurie Street | Date: 16 Feb 2016

Background

Local focus group meetings in winter 2009 highlighted an interest in validating current recommendations for ideal windrowing times in canola, particularly in the central west of NSW. One common understanding of the impact of timing was simply that windrowing too early may only reduce oil contents, and by windrowing later, yield may be lost through excessive pod shelling and shattering. Fear of the more tangible and costly loss in pod shattering had seen many paddocks being windrowed much earlier than recommended.

Grain Orana Alliance (GOA) ran multiple trials in 2009, 2010 and 2011 to examine the impact of windrowing timing on oil, yields and profitability as well as the alternate option of direct heading. One of the first trials undertaken at Coonamble in 2009 also investigated the impact on yield and oil when the crop was direct headed using pre harvest treatments with Pod-Ceal® and desiccation with Reglone®.

Methods

All trial sites were large-scale replicated trials applied to commercial, farmer-sown paddocks of canola. All windrowing and harvesting was carried out by commercial windrowers (25-40 ft swathe) and headers (25-40ft).

This methodology was chosen because it best explores the impact on yield in a full-scale context. Potential for pod shattering during the windrowing operation is a key influence over final yield and could not be duplicated in small scale trial work.

Pod shattering was quantitatively assessed at a number of the sites through catch trays. The methods used for this need further refinement to accurately represent the situation, and therefore, these details are not included in this report. It should be noted though that any yield loss through shattering is accounted for by a reduction of the final harvested yield. It is harvested yield that drives profitability regardless of shattering at any level.

Windrow timings are described as percentage colour change (CC), which refers to the percentage of seeds that have started to change colour in the middle third of the main stem of the canola plant. To determine this, 30 pods were sampled from the treatment areas, shelled out and visually assessed for colour change. This was completed three times for each replicate/plot. Once the level of CC was established the relevant treatment area was windrowed.

All windrowing timings and direct-headed treatments were harvested at the same time when all treatments were considered to be ripe enough to harvest. Yields of the whole treatment area were measured with mobile weigh bins, with the exception of at Nyngan which was weighed over a weighbridge. Grain qualities were assessed by commercial service providers using standard testing procedures.

Yields and grain qualities were assessed by ANOVA using Statistix 9 software at a 95 per cent confidence level.

Coonamble 2009

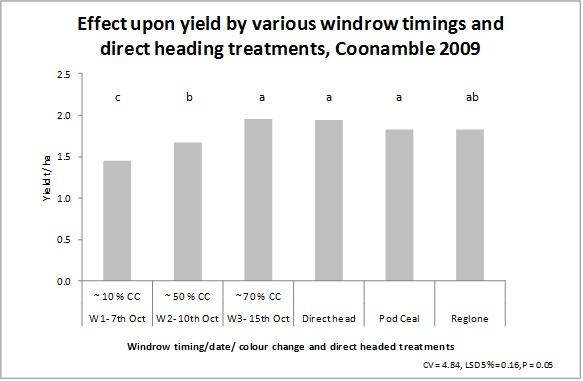

Treatments included windrowing at three timings: 10 per cent, 50 per cent and 70 per cent CC, a Reglone® (Reg) treatment at label recommendations (2.25L/ha) which was then direct headed, Pod-Ceal® (PC) at label recommendations (1L/ha) which was also direct- headed and the final treatment which was direct-headed with no other treatments. Sprayed treatments were applied by ground, but harvested areas did not include wheel track areas.

Dubbo 2009

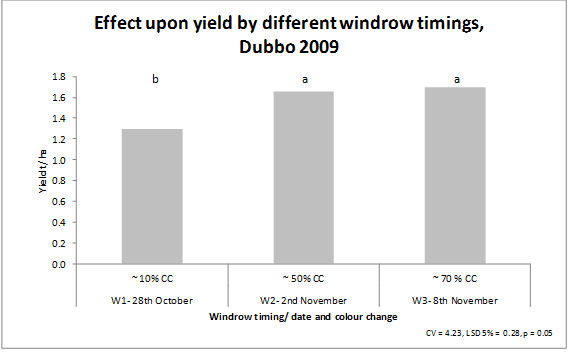

Three timings were applied in this trial 10 per cent, 50 per cent and 70 per cent colour change.

Warren (site 1) 2010

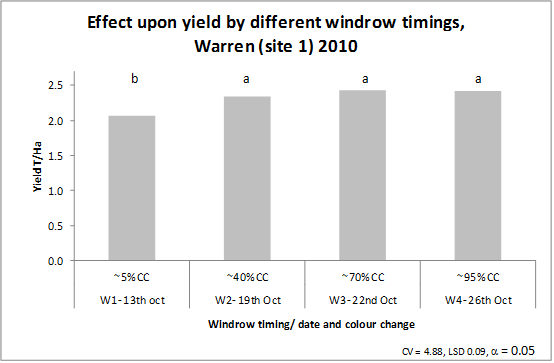

Four timings of windrowing were applied at this site, five per cent, 40 per cent, 70 per cent and 95 per cent colour change.

Nyngan 2010

Rain prevented the first timing of windrowing to be completed on time, so only two timings at 60 per cent and 90 per cent CC were applied at this site.

Warren (site 2) 2010

Three timings were applied in this trial, five per cent, 60 per cent and 95 per cent.

Nyngan 2011

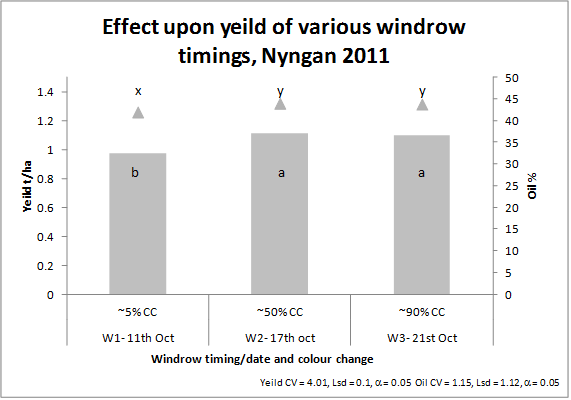

Three timings were applied at 10 per cent, 50 per cent and 90 per cent.

Warren 2011

This trial compared a single windrowing timing at 85 per cent colour change to direct-heading with a draper header front fitted with a finger reel and top auger.

Wongarbon 2011

This trial compared single windrow timing at 95 per cent colour change and direct heading with a conventional tin front and a draper front with a finger reel. A different header was used for the harvesting with a draper front than was used for the other two treatments. The header used for the windrow and conventional treatments maintained the same separator settings for both treatments.

Wellington 2011

This trial compared two windrow timings of 90 per cent CC another timing six days later (++100 per cent) and direct heading with a draper front fitted with a finger reel. The same header was used for both harvesting treatments with the same separator settings.

Results

Coonamble 2009

- Windrow timing 1 (W1) the earliest timing was the lowest yielding treatment of the three timings.

- Each of the three windrow timings are significantly different and increased as windrowing was delayed.

- The yields between direct-headed (no other treatment), Pod-Ceal®, desiccation with Reglone® and W3 were not significantly different and were the highest yielding treatments.

- Desiccation with Reglone® and W2 were not significantly different.

- There was no significant impact upon oil percentage for any windrow timing or direct heading treatment.

Figure 1: Effect upon canola yield for direct harvest, Pod-Ceal®, Reglone® and windrow treatment timings at Coonamble, 2009. Treatments headed by the same letter denotes no significant difference.

Dubbo 2009

- W1 was the lowest yielding treatment.

- W3 was the highest yield treatment but was not significantly different to W2.

- There was no significant impact on oil percentage to any timing.

Warren 2010 (site 1)

- W1 timing was the lowest yielding treatment.

- The other three timing were not significantly different to each other, but there was a trend to higher yields with delays past W1 to W3.

- Windrowing later than W3, decreased yields, but only slightly and the difference was not significant.

- There was no significant impact on oil% to any treatment.

Figure 3: Effect upon canola yield for the four windrow treatment timings at Warren, 2010. Treatments headed by the same letter denotes no significant difference.

Nyngan 2010 - no graph shown

- From a delay in windrow timing from 60 per cent to 90 per cent there was no significant difference in yield or oil%.

Warren 2010 (site 2) - no graph shown

- There was no significant impact on yield or oil at this site.

Nyngan 2011

- W1 was the lowest yielding treatment. • W2 and W3 were not significantly different, but yielded significantly more than W1.

- There was a significant response in oil percentage with W2 and W3 achieving higher oil than W1.

Figure 4: Effect on canola yield for the three windrow treatment timings at Nyngan, 2011. Treatments headed by the same letter denotes no significant difference.

Warren 2011 - no graph

- There was no significant difference in yield between windrowing at 85 per cent colour change and direct heading.

- There was no impact on oil percentage.

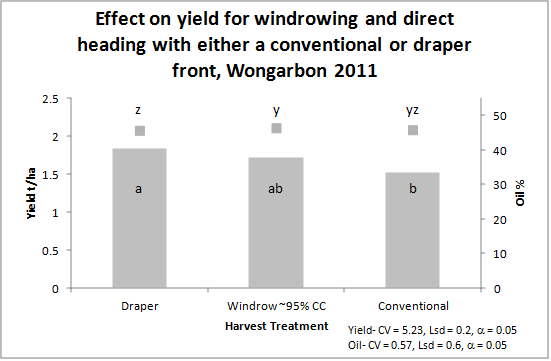

Wongarbon 2011

- It should be noted that the trial area experienced a heavy wind storm (>50km/hr) between windrowing and direct heading.

- This shattered an amount of the standing treatments. The windrows were relatively unaffected.

- Two separate headers were used for the two direct-heading treatments and it could not be guaranteed their separator configurations were the same.

- Neither style of header front was significantly different to the windrow timing of 95 per cent for yield.

- The conventional header performed worse than the draper front. However, it must be noted that there were issues with the reel of the conventional front going too fast for harvesting speed.

Figure 5: Effect on canola yield and oil percentage as a result of windrowing and direct heading with either conventional or a draper front, Wongarbon, 2011. Treatments headed by the same letter denotes no significant difference.

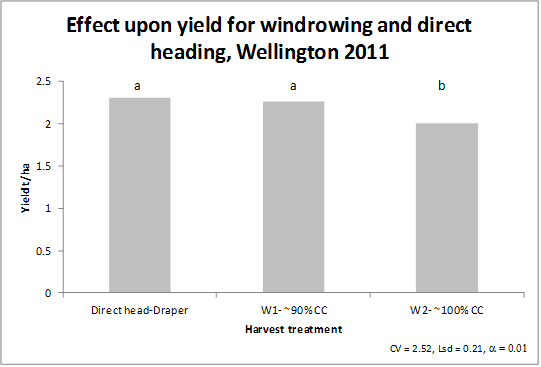

Wellington 2011

- Direct heading with a draper front was no different than windrowing at 90 per cent.

- Windrowing at the later timing (+100 per cent) yielded ~250kg/ha lower than W1 at 90 per cent CC or direct heading.

- There was no impact on oil percentage by any treatment.

Figure 6: Effect upon canola yield as a result of windrowing and direct heading, and two different windrowing timings, Wellington, 2011. Treatments headed by the same letter denotes no significant difference.

Discussion

Yield

Across the three seasons and a number of sites, early windrowing around five to 10 per cent colour change has consistently resulted in lower yields than later windrow timings. However, windrowing past the currently recommended 40-60 per cent colour change has not always resulted in further significant yield increases. It could be said that there often is a consistent trend to increase yields past these timings, with trends to decline yields slightly only at 90-95 per cent, but not statistically or commercially significant levels. However, increases in yield over a similar range have been sometimes quite significant. At Coonamble a ~250kg/ha yield improvement was realised in only a five-day delay in windrowing from a 50 per cent to 70 per cent CC timing.

This is best explained by considering the process of windrowing, whereby the plant’s growth is ceased at time of cutting when part of the crop, including seeds, are still green and growing. Once cut, key processes within the plant cease and seeds will simply start to dry down regardless of their level of maturity and grain weight. This directly prevents any further growth or grain fill of green seeds (those that have not yet reached maturity). It therefore prevents any further yield accumulation that would have occurred otherwise.

Seed maturity, when seed will no longer increase in size, can be indicated by colour change in the seed and windrowing timing is based on only a percentage of the seed within the crop having changed colour. So at the lower end of current recommended timings of 40 per cent CC there is up to 60 per cent of seed that is green, immature and still filling. Therefore, the earlier the windrowing timing the greater the proportion of seed that will not fill to its maximum potential. Therefore, delaying any action that has the potential to cease grain fill will see more seeds achieve their maximum size and hence improve yield.

Two recent small plot replicated trials run by Kathi Hertel from NSW DPI supports this theory, which is that seed growth continues up to the point of seed physiological maturity as indicated by colour change. This worked showed that mean 1000 grain weight of the seed on the main stem reaches its maximum at 77 per cent CC at the Gilgandra site and 47 per cent CC at the Wellington site (Hertel, 2012). When seed was sampled at earlier timings than this, it had a reduced size which would lead to reduced crop yields.

This potential maximisation of yield must be weighed against the risks associated with delaying windrowing or delaying to direct head. As the crop passes through the physiological mature stage and starts to dry down, the brittleness of the crop and pods increase. This exposes pods to potential shattering or splitting which would result in yield loss when the crop is either standing; before or during windrowing. The ideal windrowing stage should therefore be a balance between maximising the grown yield and not losing this increase in yield through excessive pre- windrowing or windrowing losses.

The question that should be asked then is “how much of an issue is pod shattering, and when does this start occurring?” Current recommendations and industry commentary often suggest that yield will decline through pod shattering, and the risk of this increases substantially as maturity progresses past 60 per cent CC towards 100 per cent CC. However, this has not been demonstrated in our trial work with delayed windrowing timing as detailed below:

- Warren in 2010 (site 1) demonstrated no decrease in yields between windrowing at 70 per cent or 95 per cent CC.

- Nyngan in 2010, delays from 60 per cent to 90 per cent CC showed no decrease in yields.

- Warren 2010 (site 2) showed no decrease yield by delaying from 60 per cent to 95 per cent CC.

In addition to this yield data, combinations of both quantitative and visual measurements of shattering at windrowing were made following each windrowing timing at most sites. In summary, there was no ‘concerning’ level of seed loss observed at any trial or timing, correlating well with the yield data.

However, due to bad weather at Wellington in 2011, the first of two windrowing timings were already late at 90 per cent CC. The second timing, which was well in excess of 100 per cent CC, was very late and resulted in a decrease in yield of 0.25t/ha or ~11 per cent which was statistically significant. It must be remembered that this second timing was potentially seven days later than an already late timing, so is an extreme example.

In summary, yield loss as a result of delayed windrowing timing, assumedly through shattering, has not been demonstrated except in one extreme case with very late timings and colour change in excess of 100 per cent. The belief that significant losses occur when windrowing is delayed past 60 per cent up to ~90% CC is not supported by this data.

When considering the comparisons above, also note that if any shattering was to occur it would have been most likely to occur at the late end of the range mentioned, i.e. closer to 95 per cent CC. Yields may have actually increased later than the 60 per cent timing before declining, therefore the point of maximum yield in some cases could be above 60 per cent CC. This has been demonstrated at both Coonamble and Gilgandra where measured yield or grain size was maximised at 70 per cent and 77 per cent CC, respectively.

Given that windrowing has the potential to reduce yields because it is done before all seed has matured, does direct heading have potential to capture higher yields? Four trials have shown that yields from direct-headed situations have generally only matched the yields of a well-timed windrowing (~70-80 per cent CC). However, if compared with currently-recommended windrowing timing of 40-60 per cent or earlier as can be seen at Coonamble in 2009, direct heading has outperformed the windrowing.

In the case of two different styles of header fronts being tested (Wongarbon trial site), the results could be best regarded as inconclusive. Problems with reel speed on the conventional front and pod shatter due to weather in direct heading treatments pre- harvest may have compromised the results. However despite these two negative impacts, neither header front style outperformed the windrowing at 95 per cent CC.

In considering whether to windrow or direct head canola, the Coonamble result further demonstrates an interesting point. This work has shown that windrowing timing can have a significant impact on yield over very short periods. In this situation, windrowing five days earlier than optimum has led to yield being penalised by ~250kg/ha, demonstrating a potentially small window to windrow. The question is, if timing delays for a direct headed crop will realise a similar level of impact?

Trial work was undertaken by GOA in 2013 investigating the yield impacts through delayed direct heading of canola. This trial demonstrated that the impact of delaying direct heading in canola caused a much smaller consequence than that of windrowing timing.

There are a number of new products in the market place promoted to manage potential shattering. If successful they could address one of the key concerns growers have with direct heading of canola. One such product is Pod-Ceal® which was trialled at the Coonamble site. Pod-Ceal®aims to minimise pod shatter through a coating applied over the pod. In this trial, treatment with Pod-Ceal® was not statistically different to either direct headed after desiccation with Reglone®or direct headed with no other treatment. However, this site in all treatments had minimal shattering problems. If the site experienced conditions supporting greater shattering, the advantages of such a product could well be justified. But again, how big is the issue of shattering?

Oil levels

The potential for harvest management of canola through such things as windrowing timing or direct heading has shown to have a very limited impact on oil percentage. Very few trials have shown any significant differences in oil percentage due to windrowing timing or direct heading within an acceptable window, as discussed above. Of the trials that have resulted in significant differences in oil percentage, the magnitude has been small, often less than one percent.

Oil accumulation in canola starts early after fertilisation, but often slows substantially as the seed starts to approach the later stages of development. By the time the crop reaches maturities for windrowing, accumulation has all but ceased.

Relative performance of an individual crop in terms of oil percentage should not be taken as an indication of ideal windrow timing.

Assessing crop maturity - is there a better way?

Assessing crop maturity to identify the optimum windrowing timing is not well understood or consistent with either growers or advisers (Hertel, 2012). There are many conflicting perceptions of what colour change is and what part of the plant to assess, as well as simply the ideal windrowing timing (the latter hopefully clearer after reading this paper).

Current recommended industry practice assesses crop maturity on the main stem only. However, it is worth noting that pods from other parts of the plant contribute to the overall yield potential. Changes in farming practice with reduced sowing rates and established plant populations is resulting in proportionally more grain being carried on podding sites other than the main stem measured in the aforementioned research. One mathematically calculated estimate is that as little as 15 per cent of yield may be carried on the main stem (i.e. yield 2000kg/ha = 200g/m2/15 plants/m2 = 13g/pl. Main stem seed weight = ~30pods * ~20 seed/pod = 600 seeds * 0.003g/seed = 2gm. Main stem seed weight to whole plant 2g/13g = 0.15).

Given that seed on the secondary and tertiary branches will be less mature than that on the main stem, the maturity for the whole crop would be later than what is estimated by the main stem. That is, current assessment methods have the potential to overestimate the overall crop maturity, but the magnitude of these inaccuracies will vary with plant populations.

Assuming the relationship between colour change in the main stem seed and seed weight detailed by Hertel (2012) was transferable to the whole plant, could assessing canola maturity based on colour change over the whole plant be a better estimate of crop maturity? This method would also have the benefit of making allowances for changing plant populations.

This method of assessment would, however, require further testing and calibration in the field before adoption. But, the concept is worth considering.

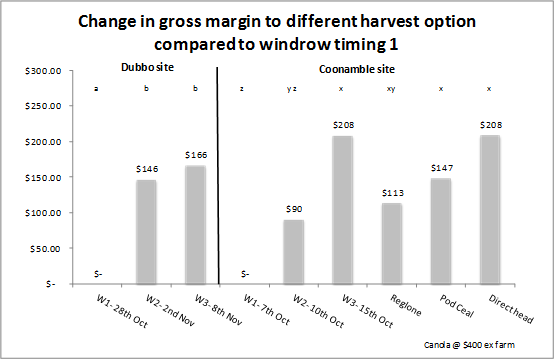

What is it all worth it?

In terms of manipulating windrowing timing to target higher yields, it should be remembered that if there is no change in costs but simply a delay in time, any increase in yield is 100 per cent profit. And the improvement in profit can be substantial, as demonstrated in Figure 7, with an extra $208/ha increase by delaying windrowing timing for only eight days at Coonamble.

Work by Hertel (2012) suggested that yield increases through delayed windrowing can be up to $50/day at their peak.

However, comparing windrowing to direct heading can be more complicated. There are obvious savings in windrowing costs when direct heading, but the rate of harvesting windrows to direct headed crops can vary. Key considerations may include the width of the windrower swathe compared with that of the header front when direct heading, but also the potential shortening of daily harvesting hours in extreme conditions when direct heading. Recently published was a Harvest Module in the Canola Technology Update 2012, which provides a lot of data and information to help compare the two harvesting options for your own circumstance.

This resource can be accessed at: Module 7 Harvest Management

However, many comparisons often suggest there is little difference in harvesting costs for direct-headed crops and those that are windrowed may have a slight cost advantage over direct heading. This is demonstrated in Figure 7 which shows similar impacts on gross margins between a well-timed windrowing and direct heading.

Figure 7 depicts the benefits for the average of all the treatments, taking into account average yields and additional costs as well as oil penalties/bonuses from Dubbo and Coonamble in 2009.

Figure 7: Change in gross margin to different harvest option compared with windrow timing W1 at Dubbo and Coonamble canola harvest trials, 2009.

Therefore, the choice on harvesting methods may depend more on other positive and negative aspects of each method rather than that of the direct economics. These aspects are covered well in the publication mentioned above. But, it is clear that windrowing timing can have a substantial impact on profitability of growing canola.

Conclusion

From these trials it could be concluded that windrowing timing has a limited effect on oil percentages in canola.

Windrowing earlier than the current recommended timings has always resulted in a significant reduction in yields which could seriously challenge profitability of crops in some situations.

The findings from these trials suggest that striving to meet the upper end of the current recommended windrowing timings is important (40-60 per cent CC) and should be targeted as a minimum, as significant yield penalties have been demonstrated consistently if cutting earlier than these levels.

However, there have been trials such as at Coonamble in 2010 and Gilgandra in 2011 that have clearly demonstrated that delaying past these times have shown to further improve yields. In all of GOA’s trials, the trends in yields have continued to increase up to 90-plus per cent CC.

One major concern with such a practice is the risk of shattering before or during windrowing when timings are delayed. These trials have demonstrated no yield penalty from delays in windrowing, except in an extreme case. Therefore, this fact infers that the magnitude of the shattering is small and statistically insignificant against any potential yield gains over the same period.

In the decision to delay windrowing later than 60 per cent CC, growers and advisers should consider that each season – or indeed each paddock - could be different. Firstly, growers and advisers should consider the crop’s current growing conditions. If the crop is experiencing terminal moisture stress delays beyond 60 per cent it may not be warranted, but if moisture is still available, even if limited, consider the findings of this work:

- windrowing later than current recommendations may or may not result in increased yields, but in some cases they have; and

- windrowing up to 90 per cent colour change has not demonstrated any significant yield decline.

So if there is a potential for improved yields with delaying till later with little downside risk, why not delay windrowing? Also remember that direct heading is an option if you cannot get the windrowing done when you need to.

Selection of varieties with greater shattering tolerance through breeding programs, changes in plant populations and farming systems, as well as better machinery, may mean that pod shatter may not be the issue that it was when the original recommendations of timings were founded. This may have contributed to this drift in an “ideal” timing recommendation which is now more than 30 years old.

Direct heading has also shown to be a suitable management option for canola, demonstrating that it often matches the performance in terms of yield of a well-timed windrowing, not so compared with ill-timed windrowing.

The choice to direct head canola, therefore, is better based upon the other pros and cons of such a practice, which are well detailed in the GRDC’s recently published Direct Heading Fact Sheet.

What these trials do hope to demonstrate is the potential economic benefit gained by getting it right. The availability of windrowers at the correct time or the other advantages offered through windrowing should be considered.

Acknowledgements

Special thanks to: Clyde Agriculture “Netherway” Coonamble; Graeme Callaghan - Graeme Callaghan & Associates, Dubbo; Garry Evans - “Larry’s Plains”, Dubbo; Lindsay Northcott, North-Hill harvesting, Young; Syngenta crop protection, Australia; Agspec, Australia (Pod-Ceal® distributors); John DeLyall- Pioneer Hi Bred Australia; “Haddon Rig” Warren; A Walker-“Erlside”, Warren; R Ledger, “Erlside”,Warren; the Waas family at Nyngan; the Street family- Wongarbon trial site; Mason Family, “Spicers Run”, Wellington; Michael White and Co., Wellington; Julie Monroe- GOA, and all other windrowers, agronomists and growers that have helped out along the way.

Funding for this work was provided through the GRDC Project GOA00001 and their support gratefully acknowledged.

References

Hertel, K A, (2012) Canola technology update. Module 7 Harvest Management V2 September 2012. Australia Oilseed Federation.

Contact details

Maurie Street

Grain Orana Alliance, PO Box 2880, Dubbo NSW 2830

0400 066 201

maurie.street@grainorana.com.au

GRDC Project Code: GOA00001,

Was this page helpful?

YOUR FEEDBACK