← Return to 2008 Planning Guide For Low-Risk Farming landing page

Published: 29 Jun 2018

Meeting the challenges of 2008

This decision-making framework is designed to help farmers identify the major decision points for the farm business and prepare for 2008.

Using this framework to prepare for the 2008 farming program will be most effective if the accompanying Key Messages (KM) are consulted as indicated.

1. Do you know the financial condition of your business?

- If not, work with your accountant and/or financial adviser to establish the financial health of your business, including off-farm investments.

return to 1 - If you do - go to 2

2. Develop a plan for managing the farm business in 2008

3. Financial/social

Do you want to keep farming?

- If so go to 4

- If not, make an appointment with your accountant and/or financial adviser to consider the options.

- If you want a break, is share farming or leasing out some of the farm an option? - return to 1

- If the business needs an injection of funds, make an appointment with your accountant and/or financial adviser to consider the options - return to 1

4. Cropping

[Key messages - Planning your cropping program, Pre-seeding]

Group your cropping paddocks into three categories:

- Definitely will seed (best paddocks) - go to 4.1

- Will seed with a good start to 2008 (average paddocks) - go to 4.2

- Will seed only if there is a great start (difficult, high-risk paddocks) - go to 4.3

4.1 These are your low-risk, high-return paddocks and should be:

- The first seeded, with dry seeding some real option.

- Seeded with high-value cereals except for paddocks which may be seeded with a break crop in preparation for 2009.

- Monitored closely to avoid major yield limiting constraints such as severe leaf diseases or nutrient deficiencies (N or trace elements most likely).

- Cereal paddocks could be grazed early for stock feed.

go to 4.2

4.2 These are your medium risk, low cost paddocks and should be:

- Seeded after the ‘definite’ paddocks to allow low-cost weed control options prior to seeding.

- Managed so they can be used for grazing or hay if necessary.

- Seeded with cereals.

go to 4.3

4.3 These are marginal high-risk, high-cost paddocks and:

- Should be left out unless early 2008 is exceptionally good

- If they are seeded, end use of the crop should be left open

- Should receive minimal inputs

- Should be seeded with cereals.

continue

5. Livestock

Key messages - Livestock

Have you done a forward feed budget and do you have enough feed for existing stock until the average break of season?

If not, options include:

- reducing stock numbers

- securing more feed

- using existing fodder more efficiently.

Consider the following:

- containment feeding will improve efficiency

- grain feeding is still economic for breeding stock

- adapt infrastructure (fencing, labour, watering) to improve efficiency

- better grazing management, for example using big mobs of similar stock moved frequently, will improve feed use without damaging paddocks.

continue

If you have enough feed to carry stock to the average break, will your current cropping plans ensure enough feed for your stock throughout 2008?

If not, consider the following:

- nominate a paddock or two of cereal for a grazing or hay if the 2008 season deteriorates

- secure more feed reserves early

- improve infrastructure to allow more efficient grazing, including more watering points in large paddocks

- refine your grazing management – including setting up for containment feeding.

go to 6

6. Revisit your business plan

Key messages - Financial and risk management

Now you have established your work plan and stock needs you can do some ‘what-if ’ scenarios and develop options to use depending on how the 2008 season unfolds, your available finance, and how much risk you are prepared to take.

continue

7. Negotiate with your financier (eg bank) for funds to undertake your work plan

- Do it early and be confident.

- Go prepared with a commitment to make it all happen and information about:

- the current status of your business

- a costed work plan for 2008

- some ‘what-if ’ scenarios to demonstrate how the bank’s investment will be protected if conditions change.

continue

8. Control summer weeds in low and medium-risk paddocks

[KM - Pre-seeding, summer weed control]

- Spray early with the lowest-cost effective chemical option under suitable delta-T conditions.

- If conditions deteriorate, adjust operation to compensate (eg, increase water rates, increase herbicide rate, switch to night spraying).

- Timely control is more important than perfect spraying conditions. Use sheep only after initial herbicide control. Don’t rely on them entirely. Maintain high levels of crop residue to maximise infiltration of rainfall and slow evaporation, and to protect the soil.

continue

9. In marginal paddocks

[KM - Pre-seeding]

- Control summer weeds with sheep

- Check soil-borne disease and fertility levels.

continue

10. Control fertiliser costs

[KM - Pre-seeding, fertiliser management]

- Use low rates of phosphorus with the seed. Supply only enough for the crop. You will not fall off a production cliff provided soil reserves of P are reasonable.

- Use only 5-10 kg N/h at seeding. More can be applied mid-season if necessary.

- Manage trace element deficiencies with seed dressings or foliar sprays.

- Be sure other nutrients (eg K or S) are deficient before applying.

continue

11. Monitor all crops and pastures closely for weeds and diseases

[KM - Post seeding]

- Early intervention is vital for cheap and effective control.

- Correct identification of pests and diseases is vital for effective control.

- Correct timing is often more important than product used for effective disease and pest management.

continue

12.

Consider your marketing options throughout the year

[KM - Marketing]

- Make sure the tool you use is the most appropriate. Is the goal maximum profit or minimum risk?

- Forward marketing transfers your price risk to the market, but not your production risk.

- Committing more than 25% of your average crop tonnage before harvest requires extra justification.

- Forward selling has little long-term benefit where yields are highly variable.

Key messages

The following guidelines contain technical, financial management and marketing information designed to be of value in developing low-risk strategies to minimise up-front costs without limiting productivity and potential profit or increasing the risk of natural resources damage.

They have been developed specifically for farmers under such financial pressure that they feel they need to change from their normal mode of operation in 2008. However, many of these guidelines will also be useful and relevant to farm businesses not under

such severe financial pressure.

Guidelines are by nature general so expert local advice should be sought before any of them are implemented in a farm business.

Financial and risk management

Risk management

- Effective management of risk and profitability is the key to success in farming. Manage to maximise whole-farm profit, not yield.

- Level of risk is a combination of the likelihood of a risk event occurring and the potential impact of that event.

- Assess risks in terms of likelihood and impact then use these assessments to rank them in terms of relative importance.

- Put strategies in place to manage the important risks.

- Some risks, like drought, can’t be managed but it is possible to adjust management to reduce their potential impact on the business.

- Inadequate managerial skills pose the biggest risk to a farm business. As well as the technical and financial issues, make sure you can manage, or have access to good advice on:

- commercial and legal issues (leases, succession)

- economic circumstances (exchange rates, commodity prices)

- environmental factors and political circumstances.

As with drought, it is important to understand and manage the potential impacts of these on farm businesses. - Develop strategies and detailed plans to manage the top 5-6 risks. These plans will be influenced by the current strength of the business and the attitude of the farm family to risk. This process requires analysis, discussion with partners and advisers and ultimately calculated judgements.

- Review these well-researched management strategies periodically and be prepared to make changes in light of new circumstances. The art of good planning is to continually monitor as the future unfolds.

- Risk management planning gives you an understanding of your real position and your options. This is the key

to ensuring the well-being of you, your family and your business.

Financial management

- If you haven’t done so already, assess the strength of the business and your options for next season. Put aside the emotional impact of 2007 and make an objective assessment of the long-term financial status of the business.

- Important parameters include:

- balance sheet (assets/liabilities)

- equity (net worth/assets)

- current budget or cash flow including actuals to date

- details of financial commitments that must be met in the coming season, including repayment schedules on large capital items, payments to family members, etc.

- cash flow budget(s) based on your optional farm programs for next year. These must include peak debt and how you plan to cover that exposure.

- Banks are interested in the long-term future for the farm. They do not want to be farm managers or take over the farm but are starting to tighten up on their lending strategies. Banks want financial details.

- Identify best, average and worst-case scenarios and show the bank the impact of various lending outcomes on your and their investment. You are making the business decisions, not them. Their confidence in you as a manager is paramount.

- Banks work on averages but will look at sensitivities to various factors. Include your views on relevant sensitivities in your case to the bank.

- Banks need to be informed about the real agronomic and other changes that are happening on farm because these have big impacts on long-term financial viability.

- Having a good succession plan is important to the bank.

- Use current interest rates in your projections. Don’t plan on Exceptional Circumstances (EC) interest rates being available in the long term.

- Some farmers may be disinclined to carry on. In these cases sale or leasing are real options. Exiting the farm business may be an opportunity, not a source of embarrassment.

- Seek outside advice. There is wisdom in discussing the options with an outsider who can be objective and may bring valuable new perspectives or information.

- Expert farm financial management is in short supply. Make sure any consultant you engage in this area has relevant training and experience.

Planning your cropping program

The information in this section was originally produced by Ross Kingwell, agricultural economist, Department of Agriculture and Food, Western Australia as ‘Planning your cropping program for season 2001’.

When funds are limited what’s the best strategy for cropping? Do you concentrate only on your ‘best’ paddocks? Do you spread your inputs more thinly over more paddocks? Do you not sow crops that require high inputs? Do you avoid crops about which you don’t have much management experience? Do you try and increase or decrease your cropping program?

The following is a check list of the important questions worthy of discussion amongst the farm family.

Identify the paddocks or parts of paddocks where your net returns to cropping are likely to be low.

These could be paddocks with potentially high weed burdens requiring expensive treatments, low fertility, potential disease problems or low yield prospects. In these paddocks a lot of money might need to be spent on seed, herbicides and fertilisers to ensure reasonable yields. These are the paddocks or parts of paddocks that you should consider not including in your season 2008 cropping program.

In assessing these paddocks you need to ask first, ‘what will it cost to crop the paddock?’ Then ask, ‘what must the paddock yield to cover that cost?’ If you think there’s little chance of getting that break-even yield then leave that paddock (or its worst parts) out of the cropping program.

You’ll find that leaving out those paddocks will help reduce peak debt and might actually increase your profits.

Take the case of three paddocks shown in Table 1.

Each paddock is 100 hectares.

Table 1: Paddock data

| | Paddock A | Paddock B | Paddock C |

|---|

|

Expected yield (t/ha)

|

1.9

|

1.6

|

1.2

|

|

Costs of production ($/ha)

|

210

|

255

|

235

|

Assuming a farm-gate wheat price of $250/t, the profit and total expenditure associated with seeding various paddock combinations is shown in Table 2.

Table 2 illustrates that including paddock C in the cropping program only increases profit by $7,000 but greatly increases cropping expenses and workload.

Table 2: Profit and expenditure from sowing

| | Sow paddocks |

|---|

| A only | A and B | A, B and C |

|---|

|

Profit ($’000)

|

27

|

41

|

48

|

|

Expenditure ($’000)

|

21

|

47

|

70

|

In real life exactly how a farm’s profit and expenditure will be affected by leaving out paddocks depends on the characteristics of that particular farm business.

Note that leaving out a paddock from the cropping program will still require some money to be spent on the paddock. Low-cost weed control and grazing costs will be incurred perhaps to set the paddock up for cropping in season 2009.

Farm management consultants are best placed to assist you with decisions about cropping programs and paddock selection. The general principle, however, is that not seeding the worst paddocks is likely to be a lower risk strategy when finances are tight.

Plan a flexible cropping program

Seasonal conditions will be a key influence on the appropriate size and enterprise mix of the cropping program. The best mix of varieties and crop types in a season with an early break is different from that in a season with a very late break. You need to ensure you have access to a range of varieties and crop types suited to the range of season possible in 2008.

It’s worth preparing farm budgets for different sorts of cropping programs so that you know in advance whether or not working capital will be sufficient and what the input requirements are for different sorts of crops.

Where working capital is limited it may be feasible to reduce some inputs with little impact on crop yield. For example, where soil phosphorus levels are high, maintenance applications of superphosphate may be foregone to save money by living “off the super bank”. Expenditure on some inputs, like nitrogenous fertilisers, can also be adjusted up or down, as the nature of the season is revealed. If you rigidly adhere to a cropping program and particular input levels you risk missing out on the benefits of “playing the season”.

It’s also worth, well in advance of crop seeding, to undertake a thorough maintenance of cropping gear so that risks of breakdown or costs of un-preparedness are reduced. Before the seeding period it is useful to think about the workload and activity sequence of the cropping program. It can help you to be proactive and less stressed during the seeding period.

Liquidating off-farm assets to provide cash for the cropping program isn’t necessarily sound business

Where off-farm investments (eg shares, rental properties) are performing better than your farm investment then it may be better to leave them alone. If you cash them in you may end up transferring money into an activity (farming in season 2008) that is more risky and less profitable! However, if you’ve a non-performing asset (eg a unit that is not appreciating much and that you rent out occasionally), then maybe now is the time to cash it in.

Now is not the time to be investing in large-scale adoption of novel crops

When funds are tight it’s usually wiser to invest in crops with which you are familiar and which display yield and price stability. Growing wheat in many situations may be preferable to growing canola or chickpeas.

Don’t be too afraid to spend money. You need to spend money to make money

Season 2008 will involve belt-tightening for many growers but remember, it’s false economy to skimp on inputs (eg weed control and fertilisers) that can significantly improve yields or returns. It’s important to spend on inputs that generate the highest return. For many farmers, 2008 will be all about obtaining the best margins on land use in each paddock.

Get the best from your input expenditure

There are a number of ways to stretch the input dollar. Use family labour rather than contract labour. Defer asset replacement where possible. Shop around to obtain the lowest price for key inputs of fertilisers and chemicals. Form a machinery syndicate to reduce ownership costs of some cropping gear (eg grain grader, deep tillage gear, hay baler). Re-negotiate HPs and leases to be on longer terms.

Seek good advice and improve your technical knowledge about cropping and livestock

The chances of a successful cropping program in season 2008 can be improved by obtaining sound advice. Consultants often have insights and knowledge worth paying for. Crop management is always evolving so it’s worthwhile to maintain your practical knowledge about how best to grow the major crops and how to spot and correct crop production problems.

Stay positive

Experience suggests that being positive has its own rewards and leads to better decision-making. Being too pessimistic and negative can lead to foregone opportunities.

Beware of ‘one glove fits all’ cropping strategies

These preceding dot-points outline some general principles for cropping programs in season 2008 but reality is that there is no “one glove fits all” best strategy for 2008.

Each farm business has its own unique resources of paddock histories, skills in enterprise management, machinery and labour availability and financial resources. How all these resources are best combined to the maximum advantage of the farm business typically involves individual strategies for individual farms. So question broad advice like ‘don’t spend too much’ or ‘crop more’ or ‘get into sheep’ or ‘sell off-farm assets’.

Get advice tailored to your farm situation and discuss options with your family to ensure sound decisions are made in season 2008.

Livestock

Livestock are seen as a major risk management tool in dryland farming systems. However, it may be difficult to apply this knowledge in 2008.

- Feeding and managing livestock through drought carries a cost so it is important to assess the likely costs and benefits before making a decision to sell down or to feed through. Every drought is different.

- Determine the long-term role livestock play in reducing risk on your farm. This will help you decide whether stock numbers need to change in 2008. Try to plan your recovery over the next few years rather than focus on last season.

- Recovery after droughts on livestock farms can be slower than on cropping farms if farmers reduce stock numbers during the drought (Holmes Sackett Ag Insights 2006).

- Don’t assume it is uneconomic to feed grain to stock at current prices. Each situation is unique and needs individual assessment. In most cases it is economic to retain and feed breeding stock.

- There are ways to utilise more of your existing dry feed. The trick is to do it without exposing the paddocks to high erosion risk. When grazing dry feed, sheep will camp less and bare out fewer patches if they are in the paddock for a short time only. Join mobs together and move them, in a paddock rotation, about once a week. Continue moving them around the rotation on a weekly basis as long as critical ground cover levels are maintained. This way the stock will lose condition more evenly.

- Water supply needs to be adequate – e.g. a 50 mm pipe with 40 mm float valve - or the sheep will camp around the trough.

- Containment feeding is relatively easy and can improve labour efficiency but should be used only once the paddock feed has been utilised. Containment feeding helps to reduce erosion and permanent pasture damage from over-grazing.

- Maintaining Merino ewes in good condition in containment areas will cost about $1.40/head/week (over 20 weeks this is $28, which will be covered by the year’s wool cut). Maintaining the breeding flock and the lambs produced make it worthwhile.

- Finishing lambs on grain will be economic only if there is a big difference in price between unfinished and finished lambs. It takes about 60 kg of feed to put 10 kg live weight onto a lamb in a feedlot.

- Supplementing with lupins in a good stubble may be cheaper (if there is no erosion risk).

- Hay may be cheaper than grain per unit of energy this year. However, pure-hay rations require slightly more energy for the stock to maintain condition (the suggested ration is about 50:50 hay:grain, depending on the relative prices). Low-quality hay (<9MJME) is unsuitable for use as a maintenance feed on its own since livestock are physically unable to consume the amount of feed of this quality necessary to supply minimum energy requirements.

- In a well-managed livestock enterprise there are very few opportunities to reduce general livestock expenses. Enterprise expenses generally increase in drought due to increased supplementary feeding costs. Labour requirements also increase during drought as there is more time required for feeding and monitoring livestock water supplies, livestock condition score and paddock cover.

- Condition score your stock regularly and draft them into ‘good’ and ‘poor’ mobs. Many stock are currently in good condition because of the high quality of available feed. Fat stock have a ‘feed reserve’ on their backs and can be fed less and allowed to slowly lose condition. Be aware that if ewes drop to Condition Score 2 their production, and that of their progeny, will be affected. However, the extra cost of maintaining them at Score 3 may not be justified at current grain prices.

- Graze paddocks susceptible to erosion last or not at all. Save some paddocks to lamb down on if your lambing starts before July.

- Agistment may be a good option this year. Costs may be less that $1.40 a week even with transport and inspection costs included. If farmers with no sheep are concerned about agisted stock bringing weed seeds onto their farm in agisted sheep, containment-feed them for two weeks on hay only to empty their gut of weed seeds. This should assure the farmer agisting the sheep that the weed seed risk is low.

- Do feed budgets to carry stock to the average season break in your district and plan what you will do if we have a late break.

- When considering dry sowing for early feed think about the true cost of the feed. If the same amount were invested in supplementary feed would you be better off ? Think about the opportunity cost of the grazing foregone while waiting for the paddock to produce feed.

- Delaying lambing until after the normal break to the season may be good management but is not a simple change and the implications need to be worked through carefully.

- Feed-test fodder and pasture for energy and protein levels. Two MJME per kilogram of dry matter could make $9,000 difference in feed cost over 2,000 sheep fed for six months where feed is bought on weight rather than energy content. Last year all feed tested (including pasture and stubble) was very high value. This year will be similar in some areas but not where later rain damaged the hay or dry feed.

- The quicker you re-build livestock numbers to pre-drought levels once the drought is over, the quicker your livestock enterprise will recover from the effects of the drought. When planning for drought recovery consider the issue of capital. The capital required to buy livestock will usually exceed the capital required to crop a given area.

- Where there are capital constraints on the business and stocking rate is well below potential, consider agistment and backgrounding during the recovery phase. The returns from these enterprises are generally lower than alternative livestock enterprises but they are relatively low-risk options.

Wind erosion control

Intensive studies of wind flow over stubble have established the following guidelines to minimise wind erosion.

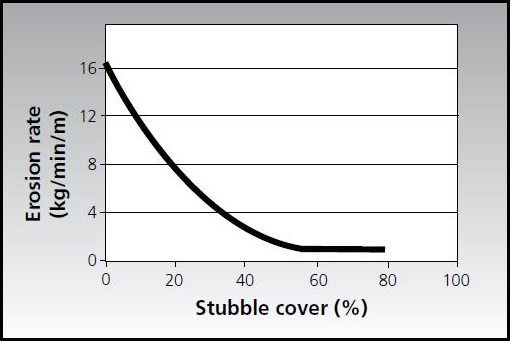

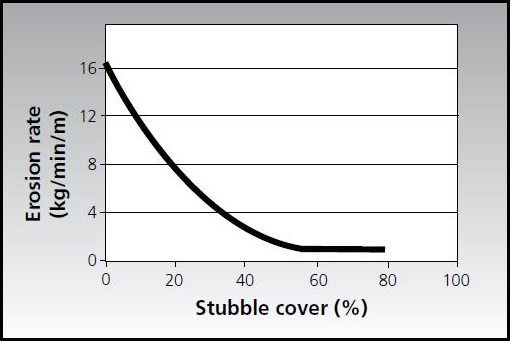

At least 50% of the ground needs to be covered by stubble (Figure 1). This level of cover will also prevent sand blasting.

Standing stubble (anchored by its roots) is twice as effective in reducing wind erosion as stubble lying on the surface.

The minimum stubble height required to prevent wind erosion is 10 cm, provided 50% of the surface is covered.

Stubbles of field pea, lentil, chickpea and faba bean should not be grazed if wind erosion control is an issue.

Figure 1. The effect of stubble cover on wind erosion

Grazing guidelines

Field pea, lentil, faba bean and chickpea - stubbles of these crops on light soils should not be grazed. Stubble on heavy soils may be grazed for a short period after harvest. Try to retain all stubble in position. A light scarifying or rotary harrowing after rain will help anchor this stubble to prevent it blowing away.

Cereal stubble - to achieve 50% ground cover requires 1 t/ha of stubble; equivalent to all the stubble from a 0.6 t/ha grain crop.

Lupin stubble - to achieve 50% ground cover requires 2 t/ha; equivalent to all the stubble from a 0.8 t/ha grain crop.

Canola stubble – 3 t/ha of canola stubble is required to achieve 50% ground cover. This is equivalent to retaining all the stubble of a 1.0 t/ha crop.

Pre-seeding

Storing summer moisture

Storing moisture out of the growing season – during summer and autumn - can effectively increase the proportion of better seasons.

Stored water is used very efficiently by the crop because it is used later in crop development and so contributes more directly to grain yield. The value of stored water was seen in 2007, when many crops performed better than expected in areas that received good summer rains.

Don’t assume soil moisture levels. Rainfall in the gauge is not the same as moisture in the soil.

Measure the amount of stored water by taking soil cores to the depth of the root zone prior to seeding but remember that not all the water present in the profile will be accessible by plants.

Consult with your adviser about how best to sample your paddocks and estimate plant available water for your situation. Many of the modelling tools designed to estimate water balance in a soil profile are not sensitive enough to account for individual paddock or zone conditions.

The pattern and timing of rainfall has a strong influence on the net benefit of summer rainfall, but in general:

- heavy soils can store more water than light soils but this tends to be closer to the surface, increasing the likelihood of losses by evaporation. Stored water in sands is usually deeper and less subject to evaporation.

- subsoil constraints such as salinity, boron toxicity and compaction can substantially reduce the volume of soil from which plants can extract water by reducing effective rooting depth.

- late summer/early autumn rainfall events are more likely to benefit subsequent crops or pastures than early summer rain, much of which will often be lost to evaporation. Do not expect to store more than 50% of the summer rain that enters the soil profile, even under the best of conditions.

- cracking soils or concentration of rain in furrows can increase penetration and so reduce evaporation.

The chances of storing ‘out of season’ moisture are improved by good summer weed control and good stubble and residue management.

Summer weed control

Effective summer weed control is vital to storing ‘out of season’ moisture. It also clears the way for easy, timely seeding. Large summer weeds can undermine a seeding program through slowed progress, poor establishment due to blockages, reduced trifluralin efficacy and the allelopathic effects of weeds that produce toxins that prevent the germination or growth of other plants.

Summer weed control needs to be early and thorough. Timeliness is critical. The key to successful summer weed control is to spray when weeds are small and actively growing.

The window for summer spraying is often much narrower than many farmers realise. Good conditions (low delta T, vigorously growing small weeds, low wind speeds) can allow efficient control with rates as low as 50% below recommended.

Do not stop spraying because conditions are not ideal; you may not get the chan e again. However, be aware of changing delta T values and be prepared to adjust chemical rates, water rates, pressures and nozzles to ensure continuing efficacy and safety in

the changed conditions.

Night spraying can substantially improve the timeliness and efficacy of summer weed control. Use the lowest-cost effective rate or tank mix. Current glyphosate costs are small in terms of $/ha and the benefits of effective weed control.

Do not rely on sheep for weed control. If sheep are to be part of the control program they are best used to clean up misses and take out later germinations after a paddock has been sprayed. When used in this way they can reduce herbicide costs by up to 30% over summer.

Cost/benefits of summer weed control

Scenario

- 25 mm rainfall event in early January on sandy loam soil germinates a population of melons, wireweed and volunteer canola.

- 35 mm rainfall event in early March causes a second germination of weeds.

| Strategy 1. No summer weed control except some grazing by sheep |

|---|

|

Chemical control costs

|

$0/ha

|

Water stored from summer events = 5 mm + 10 mm

Value of yield from the stored water (15 mm x 40 kg wheat/ha x $200/t)

|

$120/ha

|

|

Weeds not trimmed back fully by sheep delay seeding of the paddock by one day due to blockages (100 kg wheat/ha lost per week) and reduce the effectiveness of trifluralin (0.05 t/ha lost from extra rye-grass competition)

|

$-15/ha

|

| Net effect of summer rain on wheat | $105/ha |

| Strategy 2. Two herbicide sprays, followed by some light grazing by sheep |

|---|

|

Chemical control costs (2 x $15/ha)

|

$-30/ha

|

Water stored from summer events = 10 mm + 20 mm

Value of yield from the stored water (30 mm x 40 kg wheat/ha x $200/t)

|

$240/ha

|

|

Cost of yield loss from interrupted seeding

|

$0/ha

|

| Net effect of summer rain on wheat | $210/ha |

| Net $ benefit from two summer weed sprays | $105/ha |

|

Spraying the paddock twice over summer with $30/ha of chemical increased the return from the following wheat crop by:

|

$105/ha

|

Downside from spraying:

- money up front

- possible loss of some summer grazing

- potential increase in herbicide.

Upside from spraying:

- easier and more timely seeding

- fewer weed seeds carried over to the following season

- better-quality grain (more nitrogen available because less used by weeds over summer).

Residue management

Aim to maintain good cover – a combination of standing stubble and an even spread of straw – from harvest to seeding.

High levels of surface residue will enhance the amount of rainfall stored in the soil profile and slow the rate of evaporation. However, all the moisture could still be lost if there are extended periods of dry, hot conditions after a rainfall event.

Stubble cover will prevent moisture from lighter falls reaching the soil.

Enterprise and variety selection

Avoid making decisions on the run. Develop a detailed written plan for the year including strategies to handle different sets of circumstances depending on how the season unfolds. The plan should include triggers for the different strategies (e.g., no canola after the middle of May).

Aim for flexibility by identifying multiple end uses for crops, adjusting inputs and tweaking the enterprise mix.

Gaining maximum benefit from such a plan requires awareness of all the end-use options and knowing how to manage crops to achieve the best outcome if you need to change from grain to hay, for example. Management considerations include the long-term implications of strategies such as hay cutting.

Test the potential for savings or improved efficiency by setting yourself a ‘10% challenge’ to either reduce total business costs by 10% - without reducing productivity or increasing productivity by 10% without increasing costs.

Reduce risk

There may be opportunities for growers to reduce production risk by storing or arranging access to larger quantities of seed of different crop types and more varieties. This is a low-cost option that maximises flexibility. In low-rainfall areas consider keeping sufficient seed for two cropping seasons in case a drought results in no or little harvested grain.

Early seeding

Timely seeding is the single most important influence on crop performance.

The benefits from early seeding – either at the very start of the season or at a pre-determined date either ‘dry’ or after the break - appear to be increasing, partly because some of the risks from early seeding are being better managed.

Spread the risk:

- Don’t commit your whole cropping program to any one seeding option.

- Not all paddocks are suitable for very early seeding. Soil type, surface cover and weed burden all need to be considered.

- Reduce the risk of frost damage by seeding the hills first.

- If frost damage does occur, limit the losses by cutting frosted crops for hay.

When considering whether or not to seed early:

- Be aware of the real impact of the pros and cons. Delayed seeding can carry penalties but there can also be benefits, including:

- cheaper weed control, which may offset lower yield potential

- avoiding spore showers, which can reduce disease

- later development can result in less leaf disease in spring.

- You do not need to no-till to seed early but it is often an advantage because it is easier to get the crop in early without greatly increased erosion risk.

- There will be less soil moisture loss with no-till seeding.

Risks with early seeding include:

- You could lose the seed due to lack of follow up rain (low risk).

- Weed control can often be dearer (most in-crop control options will involve the use of higher-cost selective chemicals) but this can be minimised by selection of clean paddocks.

- You need very good-quality seed because germination and emergence conditions are often marginal.

- Leaf disease pressures can be higher.

- Poor operator or machinery performance can be an issue because early-seeded paddocks are the first of the season. It is important to make every effort to avoid problems because the paddocks selected for early seeding should be your best country, so any mistake will be expensive.

- Increased likelihood of frost damage.

Dry seeding

If you are not confident you can achieve good, even establishment, do not opt for dry seeding.

Dry seeding can:

- reduce seeding time when rain occurs

- maximise the length of growing season available to crops

- limit the yield reduction due to late sowing

- minimise the impact of delays due to excess rainfall reducing seeding once the break occurs

- maximise efficiency of machinery and labour.

Dry seeding is generally most successful:

- in light soils

- when the soil is very dry (not patchy or marginal)

- with less determinate crops such as canola that can mature early or late, depending on conditions

- with pulses

- where there is a low weed burden or a low-cost control strategy is available

- where wind erosion risk is low.

Dry seeding is hard on equipment due to hard, dry soil and dust.

Dry seeding works best:

- in paddocks that:

- will be seeded no matter when the season breaks

- have low, or controllable, weed burdens

- won’t erode or fill in furrows (which can result in excess soil cover and poor emergence)

- have low levels of disease and few soil-living mites and insects

- with larger-seeded species that are sown deeper

- where there is sub-soil moisture

- in soils that will provide good seed to soil contact without the risk of excessive soil throw or herbicide damage

- with crops that don’t require the use of highly soluble post-sowing pre-emergent herbicides that could cause crop injury if applied to dry soils

- where low nitrogen rates can be used safely.

Risks from dry seeding include:

- wind erosion

- inability to easily or cheaply control weeds

- seed death due to multiple small falls of rain after germination

- fertiliser toxicity

- lack of subsoil moisture to produce economic yields

- the input costs are committed whether or not the rain arrives

- the growing season does not suit the dry-seeded crop

- diseases

- insects

- poor crop establishment due to seeding depth, poor seed to soil contact or herbicide damage

- rapid early growth leading to haying off in spring.

Herbicide | Herbicide activity at germination if applied dry and incorporated by seeding | Herbicide activity at germination if applied dry before or after seeding and not incorporated | Herbicide damage potential on crop if applied dry after seeding and incorporated by rainfall |

|---|

Trifluralin | √√√ | x | x |

Triallate | √√√ | x | x |

Metolachlor | √√√ | √√√ | √ High |

Triasulfuron | √√√ | √√√ | x |

Chlorsulfuron | √√√ | √√√ | x |

Monza™ | √√√ | √√√ | x |

Diuron | √√ | √√ | √ Mod |

Simazine | √√√ | √√ | √ Mod/High |

Atrazine | √√√ | √√√ | √ High |

Metribuzin | √ | √ | √ High |

Weed control

New weed incursions

Prevention is better than control.

- There is a high probability of importing new weed species in contaminated grain or forage.

- Preventing a new weed incursion is much cheaper than managing it later.

- Weeds are likely to be moved along roadsides by/in travelling stock (e.g., in faeces, on wool) and transported in grain and hay.Check grain or forage for weed seed contamination.

Have weed seed identified.Ask vendors about the source of grain or forage and the weeds present there.Feed stock in a restricted area and record its location. - Check for emergence of new weed species immediately after the first significant rain and periodically during the next two years.

- Keep records of any new incursion.

- Develop a management strategy for new weed infestations.

Herbicide carry-over

Herbicide carry-over problems in the soil are worse following drought years due to reduced herbicide breakdown, which is of particular concern in alkaline soils.

Residual herbicides used in 2006 and 2007 may have a large impact on susceptible crops in 2008.

Individual product labels are the starting point for guidance on management of herbicide carry-over issues. Additional product-specific information is available from herbicide companies.

Plant-back periods for sensitive species are generally specified in weeks or months after application.

Following a drought, rainfall is usually the main factor affecting herbicide residues in the soil.

Plant-back periods vary with:

- species to be planted

- rate of herbicide applied

- date of application

- soil pH

- soil type

- solubility of the herbicide

- cumulative rainfall following application

- soil moisture

- soil temperature.

Table 3 provides a comprehensive list of herbicides with carry-over/plant back implications and the crops affected.

Influence of soil moisture

The chemical and biological processes that degrade herbicide residues in soil are highly dependent on soil temperature and moisture levels. They begin when soil moisture exceeds wilting point and increase in activity as soil temperature rises.

Last year’s dry conditions mean residues of chemicals applied during 2007 may persist in the soil into the 2008 season.

For example, where soil pH (in water) is less than 6.5, field peas can be sown 12 months after spraying Logran®, provided the cumulative rainfall total is more than 300mm. Less rainfall extends the plant back period.

Be aware that summer rain often has a very short-term effect due to high evaporation, particularly if falls are isolated events. This needs to be taken into account when calculating rainfall totals in the context of residues.

Options for 2008

If conditions remain dry over autumn and cumulative rainfall totals are still an issue at seeding time consider the following options:

- Choose a species or variety suited to later seeding to allow more time for residues to degrade. Field peas are suited to much later seeding than lupins. Barley is more suited to delayed planting than wheat.

- If there are residues of a herbicide such as a triazine in the top few centimetres of soil a combination of delayed seeding and more tolerant species seeded more deeply with narrow points can help the roots avoid the residue. This can be quite effective if the surface soil remains dry because this encourages the roots to grow below the residue.

- Choose crop species or varieties that are unaffected by the particular herbicide. For example, if Glean® was used in 2007, wheat would be a safe option in 2008. If Spinnaker® was used in 2007, Clearfield canola would be an option in 2008.

Paddock strip test for residues

If time is available, use the seeder to seed a test strip of a sensitive species across the paddock.

Paddock test strips are more reliable and less trouble than pot tests. The limitation is that nothing will grow until after it rains, unless a strip can be irrigated, so paddock tests could lead to seeding delays.

Weeds as a guide to herbicide residues

Herbicide residues will often lead to damage on weeds and/or volunteer plants, so examining weeds is a valid test for residues.

After it rains, carefully inspect weeds for any apparent herbicide injury symptoms. If newly emerging weeds are still being affected close to seeding time there may be a problem.

Be aware that if the herbicide has leached deeper into the soil it will take time for the roots to pick it up.

Pot tests for residues

It is possible to confirm a residue problem by seeding sensitive plants into pots of soil from the paddock.

Pot tests can be carried out well before seeding but sampling errors can lead to misleading results. Good soil sampling procedure is essential if the results are to be relevant.

Effective pot testing requires:

- a large number of sub-samples of soil taken across a representative area of the paddock

- good management of the pots with particular attention to the moisture regime. Over-watering can lead to accelerated residue breakdown.

Because of the potential for sampling and watering errors and the possibility of herbicides leaching deeper than sampling depth, a ‘no apparent effect’ result does not mean there is no residue problem.

Diagnostic tools (testing for nutrients or soil-borne disease)

The rules and procedures for diagnostic testing in 2008 are essentially the same as in any other year.

However, if a regular diagnostic program has been in place there is an opportunity to save by spending less on testing in 2008.

In paddocks where crops were monitored in 2007 and weeds are at low levels it should be possible to forego PreDicta B testing for soil-borne disease if finances are really tight. For all other paddocks PreDicta B is a good investment to protect against major disease losses and is a valuable tool for helping with decisions about what crops to plant where.

In no-till or wide-row systems it is prudent to take more samples (for example, take 30 cores if you normally take 20) to improve the reliability of the test result. With no-till, depth of sampling is especially critical because many nutrients tend to accumulate near the soil surface.

Phosphorus buffering index [PBI] is a useful tool for taking some of the variability out of P test responses.

Fertiliser management

Investing in one nutrient at the expense of others may result in unbalanced nutrition that limits the benefits from the nutrients you did purchase. If you have to cut back on fertiliser, consider cutting back on all purchased nutrients.

Crop nutrition

The need for nutrient inputs will vary from paddock to paddock. The amount of late summer and autumn rainfall and stored moisture will impact on fertiliser decisions.

The following guidelines address likely nutrient dynamics following the past few years of low rainfall. Wherever possible seek independent advice and tailor these general guidelines to your specific circumstances.

Phosphorus

The following guidelines apply to cereals, canola and most pulse crops except faba beans, which tend to be more sensitive to P supply than other species.

Phosphorus (P) must be applied at seeding for maximum efficiency.

P is an expensive input, so guessing how much is needed is not a sound business approach. It is vital to know the amount of soil P available in each paddock prior to making decisions about fertiliser rates.

Soil tests or good paddock records of previous P use will provide the necessary information about P status.

Where there is a reasonable history of fertiliser management or test results, further testing in 2008 can be foregone.

Nutrient audits using previous fertiliser rates and crop yields will also assist in making phosphorus fertiliser decisions.

There is likely to be some carry-over of fertiliser P from 2007 crops into the 2008 growing season in paddocks where the 2007 crops grew poorly all year.

Table 3: Label recommendations for re-cropping intervals of residual herbicides.

Source: Brooke White, Crop Facts Pty Ltd

| Group | Herbicide | Soil pH (water) | Months | Min rain (mm) | Crop types |

|---|

| B: Sulfonyl Ureas (SU) |

Ally®

|

5.6-8.5

|

9

|

-

|

TT & conventional canola, chickpeas, beans, lentils, lupins, peas, lucerne, medics, subclover, oats

|

|---|

|

Atlantis®

|

8.5 or less

|

9

|

250

|

TT & conventional canola, barley, oats, triticale, field peas, chickpeas, lupins, vetch

|

|

8.5 or less

|

11

|

250

|

Beans, lentils

|

|

8.0 or less

|

9

|

250

|

Lucerne, subclover

|

|

Above 8.0

|

21

|

250

|

Medic, lucerne, subclover

|

|

Glean®

|

6.5 or less

|

9

| |

Barley

|

|

12

| |

TT & conventional canola, beans, peas, lupins, medic, subclover, lucerne

|

|

6.6-7.5

|

9

| |

Barley, oats

|

|

22

| |

TT & conventional canola, beans, peas, lupins, lucerne, medics, subclover

|

|

7.6-8.5

|

18

| |

Barley, oats

|

|

24+

| |

All other crop types

|

|

Hussar®

|

8.5 or less

|

8

|

250

|

Barley, oats, triticale, beans, TT & conventional canola, chickpeas, peas, vetch, lupins, lucerne+, clover, subclover

|

|

8.5 or less

|

21

|

250

|

Medic, lentils

|

|

Logran®

|

6.5 or less

|

12

|

300

|

Peas, lucerne, lupins, medic#, subclover#, beans, chickpeas, TT & conventional canola.

|

|

6.6-7.5

|

22

|

500

|

Peas, lucerne, lupins, medic#, subclover#, beans, chickpeas, TT & conventional canola.

|

|

Above 7.5

|

12

|

250

|

Barley, oats

|

|

24

|

700

|

Peas, lucerne, lupins, medic#, subclover#, beans, chickpeas, TT & conventional canola.

|

|

Monza®

|

6.5 or less

|

10

|

300

|

Canola, chickpeas, lentils, lupins, oats, peas, subclover

|

|

12

|

300

|

Barley, beans

|

|

6.6-7.5

|

22

|

600

|

Barley, canola, chickpeas, beans, lentils, medic, oats, peas, vetch

|

| B: Imidazolinones |

Intervix®

| |

0

| |

Clearfield canola, Clearfield wheat

|

|---|

| |

10

| |

Chickpeas, beans, peas, lupins, pasture legumes, vetch, oats, triticale, barley, wheat

|

| |

34

| |

TT & conventional canola, all other crops

|

Additional requirements for non-Clearfield cereals:

- Intervix must have been applied before end of August.

- DO NOT seed if rainfall from spraying to seeding$ is less than 150 mm after 300-375 ml/ha rate, 200 mm after 375 - 500 ml/ha or 250 mm after 600-750 ml/ha rate.

|

|

Midas®

| |

0

| |

Clearfield canola, chickpeas, beans, peas, Clearfield wheat

|

| |

8

| |

Lucerne, lupins, oats, pasture legumes, vetch, triticale, barley,

wheat (lentils)*

|

| |

34

| |

TT & conventional canola

|

Additional requirements for non-Clearfield cereals:

- Midas must have been applied before end of August.

- DO NOT seed if rainfall from spraying to seeding is less than 250mm$.

|

|

OnDuty®

| |

0

| |

Clearfield canola, Clearfield wheat.

|

| |

8

| |

Chickpeas, beans, peas, lucerne, lupins, pasture legumes, vetch, oats,

wheat, barley, triticale, (lentils)*

|

| |

34

| |

TT & conventional canola

|

Additional requirements for non-Clearfield cereals:

- On Duty must have been applied before end of August.

- DO NOT seed if rainfall from spraying to seeding$ is less than 150 mm after 20 g/ha rate, 250 mm after 40 g/ha rate or 350 mm after 55 g/ha rate.

|

|

Spinnaker®

| |

0

| |

Clearfield canola, Clearfield wheat

|

| |

10

| |

Beans, peas, chickpeas, lucerne, lupins, pasture legumes, vetch, triticale, barley, wheat

|

| |

22

| |

Oats

|

| |

34

| |

TT & conventional canola, all other crops

|

Additional requirements for non-Clearfield cereals: - Spinnaker must have been applied before end of July.

- DO NOT seed if rainfall from spraying to seeding$ is less than 300 mm for rates up to 70 g/ha and 400 mm for 100 g/ha.

|

| C |

Simazine

|

9 months for all sensitive crops@ where rates up to 3.8 L have been used.

|

|---|

|

Atrazine

|

6 months for all sensitive crops@ for rates up to 2.5 L/ha and 18 months where higher rates used.

|

| I |

Lontrel®

| |

9 (<300mL/ha)

|

25+^ |

Chickpeas, peas, beans, lupins, vetch, lentils, medic, clover

|

|---|

| |

12 (300-500mL/ha)

| | |

| |

24 (>500mL/ha)

| | |

| H |

Balance®

|

7 or more

|

10 weeks

|

100

|

Wheat, barley, oats

|

|---|

|

9

|

350

|

Canola, lucerne

|

|

9

|

250

|

Beans, peas

|

|

21

|

500

|

Lentils, clover, medic.

|

NS Not specified

@ Sensitive crops include wheat, barley, oats, IT & conventional canola, pulses

( )* Proposed, not yet supported by label

$ Do not include heavy summer and autumn falls above 100 mm

# Includes natural regeneration

+ Some crop discolouration may occur at lower rainfall limit in high pH soils.

^ At least 25 mm in one event with the soil remaining moist to 10cm for one week

P application rates can be reduced when there is an early break because there will be increased mineralisation of P during the growing season.

Growers should seek specific advice but general rules-of thumb suggest:

- Apply half the normal P rate following failed crops (crops with little growth and yielding less than 0.5 t/ha).

- Use two thirds the normal rate on non-calcareous soils following drought crops yielding more than 0.5 t/ha or which had healthy growth up until late tillering. For calcareous soils, rates should be near normal.

- Normal rate on chemically or mechanically fallowed paddocks.

P fertiliser rates should be calculated to manage P supply for the 2008 crop only. Do not fertilise for the following pasture or for build up of soil reserves.

If the fertiliser budget will not cover the whole cropping program, use the calculated rates on the best paddocks first, even if it means seeding the last paddocks without P fertiliser.

Many paddocks will require some P at seeding, but consider reducing P inputs provided there is a reasonable level of available P in the soil.

Leaving off P will have little impact on production loss unless soil P reserves are very low.

Nitrogen

Paddock N status is commonly under-estimated following a drought.

Mineral N levels can be higher than normal after a drought because of the extended period of mineralisation (the drought acts like a fallow) and some carry-over of fertiliser N.

This year there is likely to be some carry-over of fertiliser N from failed crops in 2007 and increased mineralisation if there is good early rain. There will be less carry-over from crops that grew well early but failed to finish.

How much mineralised N becomes available to the crop will depend on when the break occurs, soil type and paddock history.

Soil testing can eliminate much of the guess work. N decisions for the 2008 crop should be based on deep soil N tests, particularly if aiming for malting barley.

Do an N budget as normal, taking into account soil N level, target yield and protein.

Reduce up-front cost and risk by minimising N input at seeding and plan to top-dress N in response to how the 2008 growing season develops.

Starter nitrogen (N) is important in low-N situations but adequate rates (5-10 kg N/ha applied with or near the seed) are often achieved with typical rates of DAP (or even MAP) applied to provide the P requirements of the crop.

Delay the application of any more N until well into the growing season.

You will not fall off a production cliff if you back right off N fertiliser at seeding because you can top up during the year if required.

Trace elements

Consider using a foliar spray or seed dressing to correct any trace element deficiencies. Foliar or seed dressing treatments are the cheapest option to meet the needs of the 2008 crop but will not provide any residual benefits for subsequent crops or pastures.

If you opt for a seed dressing you should also budget for a foliar spray because the seed dressing may not be sufficient to meet the needs of the crop if the deficiency is severe.

Using seed from a soil with good levels of trace elements will produce similar benefits to a commercial seed dressing.

If this seed comes from another property, be aware of the potential cost of importing weed seed compared to the cost of a commercial TE seed dressing.

If your paddocks have adequate levels of zinc (Zn) and copper (Cu) consider not applying either of these nutrients in 2008.

Disease management

Following two very dry springs in a row, the level of inoculum for many diseases is likely to be very low. Exceptions will include crown rot and Rhizoctonia. On past performance one of the rusts may also come up with a surprise.

Crown rot levels are likely to be high where cereals have been grown in close rotation.

Rhizoctonia remains a high risk in areas where this disease is an issue.

In some districts where timely rain allowed the development of good crops, there is a risk of CCN populations building up if susceptible varieties have been grown.

If in doubt about the root disease risk, have the soil tested.

The threat of rusts and powdery mildew will increase with any summer rain and subsequent growth of volunteers.

Take-all

Dry conditions in 2007 allowed very little build up of take-all in many areas. It is expected that overall levels will be low as there has not been a favourable wet spring allowing build up of the disease since 2005.

Some paddocks may be at risk as a result of local conditions including reasonable spring rain and a history of close rotations with wheat and barley or significant levels of barley grass. These paddocks should be soil tested for the disease using a PreDicta B test and the results taken into account when making decisions about what to seed where and how to manage the crop.

Paddocks at high risk should be sown to a break crop or late-seeded to barley.

If seeding wheat in paddocks with moderate risk consider:

- delaying seeding.

- treating seed with fluquiconazole (e.g. Jockey®, Jockey Stayer®, Maxiflov) or fertiliser with flutriafol (various products).

Crown rot

There is a medium to high risk of crown rot in 2008 due to inoculum build up resulting from last year’s poor finish.

The good early start to the season means that 2007 break crops will have reduced crown rot levels built up in 2006.

Local inoculum levels will depend on local seasonal conditions, paddock history, variety, soil moisture and nitrogen levels.

Barley and oats are susceptible but tolerant to crown rot and so can be a source of infection.

Durum is very susceptible to crown rot and should only be grown in paddocks known to have low crown rot levels.

Barley is least likely to show yield losses to crown rot, followed by bread wheat.

Baling cereal straw is not likely to significantly reduce crown rot levels because it leaves behind the most infected part of the plant, its base.

Burning rarely reduces crown rot levels and often increases yield losses because loss of soil cover dries out the soil.

Rhizoctonia

Rhizoctonia root rot has the potential to be widespread and severe in 2008, just as it was in 2007.

The increased severity of Rhizoctonia after drought appears due to a drought-induced reduction in the number of soil bacteria antagonistic to Rhizoctonia solani.

To reduce potential losses from Rhizoctonia:

- consider greater soil disturbance at seeding (work 5 cm below seeding depth in red/red brown earths, 10 cm in sandier soil) or cultivate to these depths in the fortnight before seeding

- ensure adequate nutrition

- avoid sulfonyl urea herbicides

- consider using a seed treatment with the ability to reduce Rhizoctonia.

CCN

CCN numbers appear to be generally low across SA judging from PreDicta B results. However, these levels may rise over time as several wheat varieties susceptible to CCN have become or are likely to become quite popular.

There are a few districts in SA that had good conditions and thick crops in 2007 and these may have allowed CCN levels to build up under susceptible varieties.

Sow resistant and moderately tolerant varieties as appropriate in the rotation.

Use the PreDicta B root disease testing service to check CCN levels if considering a susceptible or intolerant variety.

Yellow leaf spot (YLS)

Yellow leaf spot is always a threat with wheat-on-wheat rotations, especially if autumn-winter has many long damp periods.

Avoid seeding susceptible or very susceptible varieties into paddocks with large quantities of wheat stubbles.

Stripe, leaf and stem rust

Rusts are always a threat. A drought year is no guarantee of safety.

Where there is summer or early autumn rain, germination of volunteer cereals will heighten the risk of stripe, leaf and stem rust. Control volunteers by grazing or spraying to prevent build up of rust inoculum on volunteers.

Avoid growing susceptible and very susceptible varieties.

Seed or fertiliser treatments are beneficial in reducing the impact of stripe rust but crops should be monitored for rust infections with a view to applying foliar fungicides if required.

Other diseases

Spot form net blotch levels were low in 2007 and are likely to be low in 2008.

Net form net blotch caused some problems in Keel crops in 2008. Where infection occurred expect similar problems in 2008.

Inoculum of smuts and bunts will be present on and in seed following the drought. Failure to treat seed will increase the risk of building up these diseases.

There is a low risk of Septoria tritici blotch in wheat and scald in barley. Early seeding and wet weather in winterspring can increase the risk from these diseases.

Canola

Re-seeding failed canola crops in 2008 could result in serious disease management issues and is not recommended.

Assess the disease risk for each paddock and choose the lowest-risk options.

Do not seed canola or a pulse into a stubble of the same crop and be aware that residual 2006 crop stubble may harbour disease.

Follow disease management guidelines. Select tolerant varieties and assess the effect of autumn rainfall on disease levels. Review seeding time, control grass weeds and consider seed dressings.

Consider a seed dressing to provide protection against earth mites.

Blackleg

Avoid seeding canola into or adjacent to canola stubble.

Do not consider canola-on-canola in paddocks with more than 100 kg/ha of stubble.Even 100 kg/ha of stubble will produce moderate numbers of spores. There is typically more than 1,200 kg/ha of canola stubble present after the following cereal crop has been seeded.

If seeding into a high risk area is the only option available, use all management precautions possible:

- check for blackleg on remaining stubble including pieces beneath the soil

- choose a variety with a blackleg resistance rating of 7 or above

- use a fungicide with the fertiliser or a fungicide seed coating

- be aware this is a high-risk option.

Sclerotinia

The risk from sclerotinia remains unchanged for 2008, with the impact of the disease determined by seasonal conditions.

Pulses

Seeding pulses on pulses increases the risk of crop failure in seasons favourable for disease development.

With many pulse crops failing because of the drought it will be tempting for growers to re-seed paddocks to the same crop or another pulse in 2008.

However, this is not advisable, given the potential of even minimal residues to harbour disease inoculum and the ability of diseases to build up rapidly under the right conditions.

This year’s pulse crops should be a minimum of 500 metres from any 2007 or 2006 stubbles of the same pulse.

Adverse growing conditions can increase the risk and impact of disease so consider soil pH, waterlogging risk and residual herbicides when deciding where to plant pulses.

Narrow-leaf lupin seed should be tested for cucumber mosaic virus. Albus lupin seed should be tested for bitter-seed contamination.

Be aware that:

- many of the common diseases of pulse crops can survive quite well in dry years. Old stubble residues can harbour many foliar diseases such as:

- ascochyta diseases of chickpeas, lentils, field peas and faba beans.

- botrytis diseases such as grey mould of lentils and chickpeas and chocolate spot of faba beans.

- several common diseases can survive in the soil in the absence of stubble residue. These include:

- phoma stem blight, which can infect field peas and chickpeas.

- downy mildew of field peas.

- Botrytis fabae, which causes chocolate spot in faba beans and grey mould in lentils.

- Sclerotinia.

- root rot pathogens such as Phytophthora and Pythium can survive under dry conditions but are strongly dependent on soil moisture to become active. These pathogens are present in the soil at low levels and cause damage to plants under very wet conditions.

Field peas

Do not seed peas into a paddock that grew field peas last year.

There is minimum risk of disease to field peas provided they are not sown adjacent to pea stubble and the previous pea crop in the paddock was at least four years ago.

Bacterial blight of field peas, the most important bacterial disease affecting pulse crops, can survive on infected seed and stubble for more than 12 months.

- Any stubble residue present from 2006 field pea crops may also harbour viable bacteria that could infect crops in 2008.

Chickpeas

Chickpea ascochyta survives on chickpea residue, infected seed and volunteer chickpeas.

If there is enough rain during summer to establish volunteer chickpeas, some will carry ascochyta. Destroy volunteers as soon as possible and follow the ascochyta disease management recommendations.

Despite the drought, virus levels were high in many pulse crops in 2007.

Table 4 sets out the important diseases for each pulse crop and the threats they pose to following crops.

| Disease | Pathogen |

|---|

|

Ascochyta blight

| Ascochyta rabiei (chickpeas)

|

|

Ascochyta (Blackspot)

| Ascochyta pisi (field peas)

Phoma medicaginis

Mycosphaerella pinodes |

|

Ascochyta

| Ascochyta lentis (lentil)

|

|

Ascochyta

| Ascochyta fabae (faba bean)

|

|

Grey Mould

| Botrytis cinerea

Botrytis fabae |

|

Chocolate spot

| Botrytis fabae |

|

Phoma

| Phoma medicaginis |

|

Sclerotinia

| Sclerotinia sclerotiorium |

Table 4. Flow-on effects of pulse diseases

| 2006/7 Pulse crop | 2008 Pulse crop |

|---|

| Field pea | Lentil | Faba bean | Chickpea |

|---|

|

Field pea

|

Ascochyta (Blackspot) XXXX

Sclerotinia XX

Downy mildew XXX

Powdery mildew XXX

|

Phoma XX

Sclerotinia XX

|

Ascochyta blight XX

|

Sclerotinia X

|

|

Lentil

|

Phoma XX

Sclerotinia XX

|

Ascochyta XXXX

Grey Mould XXXX

Sclerotinia XX

|

Chocolate spot XXX

Sclerotinia X

|

Botrytis grey mould XXX

Sclerotinia XX

|

|

Faba bean

|

Mycosphaerella pinodes XX

Sclerotinia XX

|

Grey Mould XXXX

Sclerotinia XX

|

Ascochyta XXXX

Chocolate spot XXXX

Sclerotinia X

|

Sclerotinia X

|

|

Chickpea

|

Sclerotinia XX

Phoma XX

|

Grey Mould XXX

Sclerotinia XX

|

Sclerotinia XX

|

Ascochyta blight XXXX

Grey Mould XXX

Sclerotinia XX

Phoma XX

|

Table 5. Pulse best options

| 2007 Crop | (Left to right) 2008 Best crop option to worst crop option |

|---|

|

Field Pea

|

Faba Bean

|

Lentil

|

Chickpea

|

Field Pea

|

|

Faba Bean

|

Chickpea

|

Field Pea

|

Lentil

|

Faba Bean

|

|

Chickpea

|

Field Pea

|

Faba Bean

|

Lentil

|

Chickpea

|

|

Lentil

|

Field Pea

|

Chickpea

|

Faba Bean

|

Lentil |

Manage the risk

The risk of crop losses from the pulse diseases above can be reduced by good management.

To minimise the risk of disease damage to pulses:

- do not seed the same pulse crop species in the same paddock.

- select pulse crops with the lowest disease risk.

- use a fungicide seed dressing or ‘in furrow’ fungicide to provide protection from early infection by root rot pathogens.

- graze lightly, burn or incorporate residues shortly before cropping to reduce inoculum levels for the following pulse crop.

- be aware of the potential for volunteers to emerge in following pulse crops. These self-seeded plants can be a source of inoculum and seed from them can contaminate the crop if they are allowed to mature.

- don’t let self-seeded plants establish as a substitute crop. Self-seeded crops that emerge early become a nursery for disease and usually fail due to high disease pressure.

Any pulse crop seeded into a failed pulse crop - including new varieties with improved disease resistance - has a high disease risk and should be managed accordingly.

Post-seeding

Weed management

Maintain effective weed management strategies. Cutting back on weed control to save costs in the short-term is not cost-effective because of the high future cost of higher weed densities.

Controlling weeds early is always the most effective and cheapest strategy, regardless of circumstances.

Weed management options in the wake of the drought will vary depending on soil type and the cropping system.

Key issues include:

- impact of dry conditions on potential herbicide carry-over

- impact of rotation changes on weed management.

When controlling weeds for 2008, keep in mind your long-term goal of running the seed bank down.

Use residual herbicides wherever practical.

Low-technology weed maps made on the header during the previous harvest using a pencil and paper (just mark areas of low, medium or high weed density) are useful management tools.

Such maps can provide important information about weed seed banks and may enable you to reduce costs by using high-cost chemicals to ‘patch out’ weeds instead of spraying fence-to-fence.

Pest management

Accurate identification of the pest is essential for effective pest control. It is also important to identify beneficials that may help control the pest.

Monitor pest populations and, before setting out with a tank load of pesticide:

- ensure the insect you suspect is in fact causing the damage

- be sure that the damage occurring is sufficient to warrant spraying (varies with crop value).

Be aware that aphids are vectors for several viruses that can cause serious diseases in crops.

Correct identification and effective monitoring are both essential skills for low-cost and effective pest and weed management.

Correct timing of fungicide applications is critical and in some instances can be more important than the type of product used.

Aphids and viruses

Aphid numbers were above average in most regions in 2007, particularly in cereals. If conditions are right for insect activity it will be important to monitor crops closely and control aphids when numbers exceed thresholds. This is particularly important in areas at risk of Barley Yellow Dwarf Virus (BYDV). Low densities of aphids can transmit BYDV, with earlier infection resulting in higher levels of damage.

Predators and parasites should be encouraged as a natural way of suppressing aphid numbers. These can be a very reliable form of control when low to moderate numbers of aphids are present.

If chemical control is necessary, consider using ‘softer’ chemicals (such as pirimicarb) that are aphid-specific and less harmful to other insects.

Earth mites

Earth mites - redlegged earth mite, blue oat mites, clover mite and Balaustium mites – were affected by the dry conditions in some areas in 2007. Spring populations were generally lower than previous years and this will result in lower numbers this autumn.

However, in many areas numbers were still relatively high and monitoring will be important, especially in the first three to five weeks after seeding.

Avoid ‘insurance’ sprays and rotate chemical groups if using chemicals to avoid insecticide resistance problems.

Mite species vary markedly in their biology and response to chemicals so it is important mites are correctly identified.

Lucerne flea

Lucerne flea numbers were lower in the spring of 2007 than in previous years in many regions, but if summer conditions remain dry numbers could still be high this year.

Lucerne flea attack all crops and pastures, with lucerne and clovers particularly susceptible. They are mostly found on loam/clay soils and in areas with high humidity and moisture, such as irrigated pastures.

Keep a close watch on these areas during autumn, when emerging crops and pastures are most at risk.

Native budworm

Native budworm numbers were high in many areas in 2007. They are likely to be a problem in 2008 as crops start to set grain. Crops most likely to be attacked are pulses, lucerne, subclover and annual medic seed crops. Native budworm will also attack canola and cereals.

Larvae of native budworm feed on buds, flowers, fruiting parts and seeds. Crops should be closely monitored using a sweep net from early flowering to maturity. Pod inspections are also essential to detect small grubs and accurately determine numbers.

Rotations

It has been common practice to re-seed paddocks to the same crops in the year following a drought rather than continuing the rotation. In the past (e.g., after 2002 and 2005) this has generally been very successful but in 2007 this practice produced widely varying results from district to district and farm to farm. This suggests each paddock must be considered in light of what happened with the 2007 crop, particularly:

- Were root or foliar diseases present?

- How much stubble was produced and will carry through into 2008? Where good opening rains in 2007 encouraged early growth and diseases such as yellow leaf spot in wheat and spot form of net blotch in barley it will not be appropriate to re-seed the same crops in 2008.

For 2008:

- Choose varieties best suited to your area and needs.

- Don’t assume when the season will break. Select varieties from a range of maturity groups.

- Only use seed with high germination levels, ideally above 90%. Seed lots with a germination below 70% should be used only if no other seed is available.

- Select seed from weed-free paddocks.

- Select seed that has at least reached soft dough stage and has most grains wider than 2 mm.

- Grading of seed may improve germination rate but may not be cost-effective.

- Have seed tested for germination capacity by an accredited laboratory.

- Don’t seed drought-affected seed dry or too deep and avoid seed or herbicide treatments that may reduce coleoptile length.

- Keep accurate records of what seed is stored where and mark the variety and source on the silo.

- Be aware of your responsibilities under PBR legislation.

Wheat after wheat

- Look at crop performance and disease levels in 2006 and 2007 crops to guide the decision on whether or not wheat on wheat will be safe.

- Take-all, crown rot, rhizoctonia and cereal cyst nematode (CCN) are the major soil-borne threats to a second wheat crop. Assess paddock performance in 2007 to check if these were a factor.

- CCN has been uncommon in the past 5-10 years due to use of resistant varieties, control of grass weeds and rotation management. Don’t compromise management of this disease for one extra wheat crop.

- Take-all is favoured by warm, wet springs and high stubble carry-over, so is unlikely to be a problem in 2008 except in some isolated areas. If in doubt have a root disease test conducted.

- Ensure all host grasses and volunteer wheat are controlled for at least two weeks before seeding.

- Yellow leaf spot is the main foliar disease threat with wheat on wheat rotations and only a few varieties have useful resistance to this disease. Infection will be carried over from stubble residue remaining after infected 2007 crops. It will have greatest impact on susceptible varieties seeded into infected stubble, followed by a cold, wet winter.

- Crown rot was common in 2007 due to the harsh spring conditions. Avoid seeding durum wheat varieties into any infected 2007 wheat stubble.

- If concerned about levels of disease consider growing barley or a broadleaf crop instead.

- Risk of rust is not necessarily increased by re-seeding wheat because rust spores are wind-spread over large distances.

- As the 2008 seeding window approaches assess the effect (if any) of summer and autumn rainfall on disease levels and review seeding time or change the crop plan accordingly.

- Consider the implications of this year’s decisions for future rotation management and plan how to manage 2009 crops.

Barley after barley

- Spot form of net blotch (SFNB) and CCN are the main risks.

- Seeding varieties more susceptible to SFNB into infected 2007 stubbles is not recommended, especially in higher-rainfall environments.