Breeding for imidazolinone tolerant barley varieties: industry issues and concerns

Author: David Moody, InterGrain Pty Ltd, Bibra Lake, Western Australia | Date: 25 Feb 2015

Key messages

- New imidazolinone (IMI) tolerant barley varieties offer substantial immediate benefits to growers in many growing regions of southern Australia. Breeding for tolerance to IMI herbicides requires considerable investment by breeding companies and is high risk in terms of the marketability of trait at the end of a breeding cycle of 6 – 10 years.

- Exceedance of MRL’s in grain samples produced with inappropriate use of these herbicides will have enormous economic consequences for the Australian grains industry.

- Development of tolerance to IMI herbicides in target weed species is inevitable without strong stewardship programs to protect these herbicides.

- Failure of the industry to adopt stewardship programs is a major disincentive for breeding programs to continue breeding for herbicide tolerance.

Aims

Development of the next generation of the IMI tolerant barley varieties is a key objective of the InterGrain barley breeding programs. In the development of these varieties, InterGrain is recognisant of the likelihood of the evolution of tolerance to these herbicides amongst target weed species and the potential for maximum residual levels (MRL’s) to be exceeded in grain samples when these herbicides are used in an inappropriate manner. For these reasons, InterGrain, in partnership with Agriculture Victoria Services (AVS) and Syngenta, is committed to the promotion of herbicide stewardship approaches that both prolong the useful life of this highly valuable technology and prevents any breaches of MRL’s that would harm Australia’s reputation as a producer of clean, high quality and safe food products.

Method

Economic value

The value of the IMI tolerance trait can be estimated from either (i) an assessment of the adoption rate of tolerant crop varieties or (ii) detailed examination of the frequency and distribution of the target weed species combined with estimates of costs of control and costs of failure to control the weed species.

For barley, the variety Scope is essentially identical to its progenitor Buloke for all traits except for tolerance to the IMI herbicides; the rate of substitution of Buloke by Scope provides a relatively simple guide to the value of the trait amongst Western Australian barley producers. Further evidence of the trait value stems from the comparison of gross returns derived from the IMI tolerant varieties in weed-free environments compared to alternative feed and malting varieties. In this paper, gross returns for Scope competitor varieties are calculated using 2014 NVT individual variety by site yield and grain receival data, and prices of $280 per tonne for Baudin Malt 1, $270 per tonne for Malt 1 for other varieties, $255 per tonne for Hindmarsh Malt 1, and $240 for feed barley. Comparative gross margins are used to provide a base economic value for each variety, with the departure in adoption rates of varieties from those suggested by relative gross margin returns providing an indication of relative value of other characteristics of those varieties in the farming system.

Breeding

InterGrain has an exclusive licence from AVS for the use in breeding of the patented IMI tolerance trait in barley (Materne et al, 2009); the tolerance derives from an induced mutation in the acetohydroxyacid synthase (ALS) enzyme of the variety Scope. The mutation present in Scope at base position 1742 of the ALS gene results in a serine (Ser653) substitution in the E domain of the ALS enzyme. A Ser653 substitution in ALS confers high levels of tolerance to IMIs but not to other ALS inhibitors such as the sulfonylureas and trizolopyrimidines; tolerance to other ALS inhibitors derives from mutational events elsewhere in the ALS gene (summarised in Lee et al., 1999). InterGrain investments in the development of IMI tolerance barley varieties exceed $500,000 per annum. Through conventional breeding techniques, InterGrain has transferred tolerance to the IMI herbicides from Scope into a range of genetic backgrounds, including 5 doubled haploid lines evaluated in the 2014 season NVT trials. The performance of one of these lines (IGB1334T) will be discussed in this paper.

Risk assessment

Principal drivers for the selection of herbicide resistance within weed species are (i) the starting weed population size, (ii) initial frequency of herbicide resistance weeds in the population, (iii) the efficacy of weed control, (iv) the frequency of herbicide application, and (v) the level of adoption of alternative weed control strategies. Estimates of these drivers for IMI resistance evolution, and current weed herbicide resistance status, are available from research undertaken by the Australian Herbicide Resistance Initiative (AHRI) and from knowledge of the relative production of IMI tolerant crop cultivars.

Results

Economic value of IMI tolerance value

Surveys conducted by AHRI indicate approximately 20% of Western Australian paddocks contain significant brome grass populations (M. Walsh pers. comm.) but detailed information describing the frequency versus density in brome grass populations across the State is not available. Assessments of the competitiveness of brome grass in wheat by Gill et al (1987) indicate an exponential relationship exists between yield loss and brome grass plant density; that is, relatively small increases in brome plant densities cause significant decline in yield, with densities as low as 50-60 brome grass plants per m2 reducing yield by 20%. Avoidance of this scenario is driving growers to adopt significant brome grass management strategies when populations approach 30 plants per m2. Whilst the majority of Western Australian paddocks still have relatively low brome grass populations (less than 10 plants per m2), there is a continuing trend in No-Till farming systems towards brome grass becoming a more problematic weed.

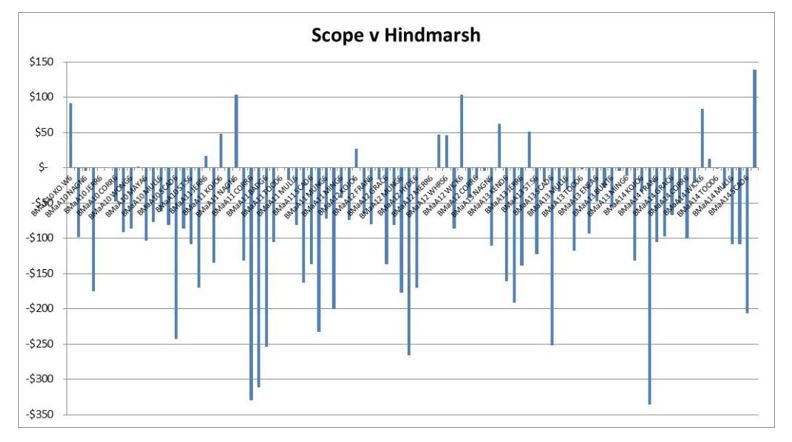

It is estimated from grower surveys that since the release of Scope, the area sown to this variety has grown faster than any other variety - from negligible areas in 2012 to over 20% of the barley acreage in 2014. Largely this growth has been at the expense of Buloke, although Scope has also eroded the area sown to some other varieties. Yields of Buloke (released in 2005) and Scope are now significantly lower than varieties such as Hindmarsh. A comparison of gross returns for Scope and Hindmarsh assessed in NVT between 2010 and 2014, using trial yield and grain quality data, and typical prices received for each of the varieties, indicated the average gross returns of Scope were over $70 per hectare lower than for Hindmarsh (Figure 1). Given that Scope offers no obvious improvement to growers other than IMI tolerance, the very rapid rate of adoption of this variety provides a very clear indication of the value this trait in barley provides to the farming system as perceived by growers and advisors.

Figure 1: Comparative gross returns ($/ha) of Scope versus Hindmarsh in all Western Australian NVT from 2010 – 2014. Deviations from the x axis represent either positive or negative differences in gross returns after taking into account, yield, grain quality and prices of $240 per tonne for feed, $255 per tonne for Hindmarsh Malt1 and $270 per tonne for Scope Malt1. The malting prices were only used for Scope and Hindmarsh at those sites meeting grain receival standards for Malt 1 (protein, test weight, screenings and colour); the feed price was use for both Scope and Hindmarsh when the variety failed to meet Malt 1 receival standards.

Breeding progress

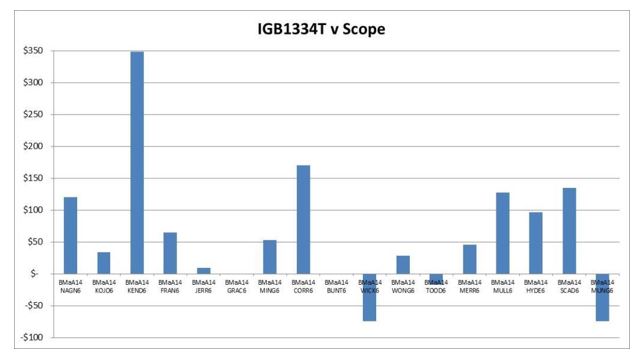

Long-term results from InterGrain’s national trialling system indicate that IGB1334T is at least 10% higher yielding than the IMI tolerant variety Scope. Based on 2014 NVT trials in WA, the yield advantage provided by IGB1334T equated to an average improvement in gross returns of $75 per ha (Figure 2). IGB1334T has the “Hindmarsh” plant type, being relatively short and possessing the ari-e semi-dwarf mutation, which provides for a high harvest index. Experience with this plant type indicates good establishment and high shoot densities are critical to maximising yield performance. IGB1334T has similar maturity and physical grain quality to Hindmarsh and, like Hindmarsh, is prone to poor establishment if sown too deep under adverse plant establishment conditions (heavy clay soils, significant rainfall following sowing, soil surface crusting). On lighter soil types, where brome grass is most prevalent, such establishment issues are less likely. Like Hindmarsh, IGB1334T is relatively early maturing; time of sowing trials with these plant types (specifically Hindmarsh and La Trobe) in the eastern Australia indicates they respond favourably to earlier sowing with early to mid-May sowing being optimal in most environments, generally before a non-selective herbicide can be used for brome grass control.

Figure 2: Comparative gross returns ($/ha) of IGB1334T versus Scope in all 2014 Western Australian NVT. Deviations from the x axis represent either positive or negative differences in gross returns after taking into account, yield, grain quality and prices of $240 per tonne for feed and $270 per tonne for malting. The malting price was only used for Scope at those sites meeting grain receival standards for Malt 1; the feed price was use for Scope at sites failing to meet Malt 1 standards and was used for all sites for IGB1334T.

Risk assessment

Based on estimated percentages of IMI tolerant crops in Western Australia (barley 20-25%; wheat 3-4%; canola 5%) the total area to which IMI herbicides could be applied is approximately 520,000ha or 7% of the area sown to barley, wheat and canola. This area has grown from approximately 200,000ha prior to the release of Scope.

A survey on the IMI resistance status of brome grass populations across Western Australia was last conducted by the UWA Australian Herbicide Resistance Initiative in 2010; the next survey of brome grass by the AHRI is to be conducted in 2015. Fortunately the 2010 survey did not detect any brome grass populations with resistance to IMI chemistries, but six populations were identified with low level resistance to sulphonyl urea herbicides, with resistance postulated to be due to enhanced metabolism of the herbicide as opposed to target site (ALS gene) mutation (Owen et al, 2012). To date there is no evidence that those brome grass populations found in Western Australia with the enhanced metabolism of the sulphonyl urea herbicides also have enhanced metabolism of IMI herbicides.

Extensive research has conducted in many species on the evolution of resistance to ALS inhibitors, including the identification of the frequency of tolerant types in initial (previously unsprayed) populations (eg Preston and Powles, 2002; Tranel and Wright, 2002). Whilst studies have not yet been reported on the initial frequency of resistant plants within brome grass populations, the research on other species would strongly suggest the inevitability of brome grass with resistance to the IMI herbicides already existing within the Western Australian brome grass populations. A recently confirmed case of high levels of brome grass resistance to IMI herbicides at Lameroo, South Australia, is insightful. Two successive applications of IMI herbicides to an initially very large brome grass population, that had never previously been subject to control by IMI herbicides, selected a brome grass population tolerant to 5-6 times recommended rates of IMI herbicides (Kleeman, S. pers. comm). Such a rapid rate of evolution indicates the initial frequency of resistant individuals, in some previously unsprayed brome grass populations, may be quite high.

Apart from the evolution of weed resistance, the second major risk associated with the use of IMI herbicides arises from grain contamination. Customer reaction to the detection of residues of imazapyr and imazapic in barley samples in Victoria in February 2014, which exceeded both Australian standards and Japanese import tolerances, has highlighted the risk that unacceptable herbicide use poses to market access. In this case, the actions of a few growers potentially jeopardised all barley exports from Australia to Japan. Australia remains under close scrutiny with the Japanese Ministry of Agriculture, Forestry and Fisheries increasing testing of all barley shipments from Australia for the next five years. Exceedance of MRL’s is entirely avoidable if label instructions for use are followed.

Conclusion

In terms of the evolution of resistance to IMI herbicides, the current percentage of the cropping area (ca 7 -7.5%) being sown to tolerant crops is not of high concern provided appropriate stewardship approaches are adopted. The risks increase, however, with the release of IMI tolerant varieties that are economically competitive with other conventional varieties; the temptation to use IMI herbicides more regularly then grows. This would particularly be the case should an IMI tolerant wheat variety be released that is highly competitive with other non-tolerant varieties. In this context, the Western Australia industry is at a key point in the management of brome grass. Appropriate stewardship of the herbicides now may enable a considerable useful life expectancy of the technology; the converse also applies. Key aspects of stewardship should include the following:

- Avoidance of the use of IMI herbicides on large brome grass populations; alternative management strategies should be adopted for initial control including spray topping pasture/fallow paddocks.

- Usage of IMI herbicides only twice in a four year period, preferably at full rates factoring in the potential need to sow a tolerant crop the subsequent year if soil residue issues are a concern. Never use IMI herbicides on either successive crops or the use of IMI herbicides in summer fallow situations following or preceding the use of the herbicide in-crop.

- Consider the use of alternative herbicide groups that provide brome grass control in a cropping rotation.

- Never use IMI herbicides twice in the one season, regardless of the temptation to control late germinating brome grass. Not only is this extremely poor management in terms of controlling the evolution of herbicide resistance, but is likely to lead to breaches of MRL’s with very serious consequences for the whole industry.

- Use of other in-crop selective herbicide groups in a cropping rotation where possible, and adopt harvest weed seed management to destroy brome grass weed from plants either resistant to, or avoiding, control.

- Consider carefully which tolerant crop species best suits the individual paddock or farming system. The strengths and weaknesses of each crop species should be considered:

- Canola offers a range of in-crop herbicide options including Group A, Group C (TT types) and Group M (RR types), in addition to IMI tolerant types, and its early harvest offers improved efficacy of harvest weed seed management strategies.

- Barley is a vigorous weed competitor, the Group C herbicide metribuzin can be used for brome grass control, and, like canola, barley’s relatively early maturity improves outcomes from harvest weed seed management strategies. The competitive performance of the newer IMI tolerant barley varieties, to become available in 2016, compared to competitor conventional varieties also allows the adoption of an IMI tolerant variety in the barley phase of a crop rotation without the financial penalty.

- For wheat, the range of brome grass control options is more limited. Widespread resistance exists for other Group B herbicides available for brome grass control in wheat; wheat is less competitive than barley, resulting in higher yield losses from brome grass, and its later maturity results in a lower efficacy of harvest weed seed management with only 70 – 75% capture of seed (M. Walsh pers. comm).

Failure of the industry to adopt stewardship programs has three significant consequences:

- Substantial grains industry economic losses resulting from potential breaches of MRL’s through off label use.

- A rapid evolution of resistance in brome grass populations.

- An even more rapid withdrawal of breeding companies from working on the development of herbicide tolerant crops, with the next generation of farmers no longer provided with this valuable management tool.

References

- Gill G.S. et al (1987) Australian Journal of Experimental Agriculture 27, 291-294

- Lee et al. (2011) Proceedings of the National Academy of Sciences 108, 8909-8913

- Materne, M. Pittock, C and Moody, D.B. (2009). Herbicide resistant barley

- Owen M.J. et al (2012) Pest Management Science 68, 1077 – 1082

- Preston C. and Powles S. B. (2002) Heredity 88, 8-13

- Tranel P.J. and Wright T.R. (2002) Weed Science 50, 700-712

Acknowledgments

Valuable discussions with Dr. Michael Walsh (AHRI), Dr. Sam Kleeman (UA) and Mr. Trevor Gillespie (BASF) are gratefully acknowledged.

Was this page helpful?

YOUR FEEDBACK