New technology for improved herbicide use efficiency

Author: Sam Trengove and Stuart Sheriff (Trengove Consulting) | Date: 30 Jul 2015

Take home messages

- Site specific herbicide application can optimise weed control while minimising herbicide cost.

- The economic return from site specific weed management (SSWM) with herbicides cannot exceed the cost of the highest cost herbicide applied unless the herbicide has a phytotoxic effect on the crop that reduces yield.

- High density weed patches should be targeted with high efficacy treatments over several years to deplete the seed bank.

- Next generation weed identification sensors are being investigated for use in Australia.

Background

Site specific weed management (SSWM) has the potential to deliver significant improvements in weed control efficiency, through the targeted application of weed control measures only to where the weeds are located. Improvements in weed control efficiency will typically be achieved through reduced herbicide usage where herbicide is not required. SSWM has four principal components:

- Weed identification: Locate and identify weeds.

- Treatment decision: Make decision on appropriate treatment to control the weeds.

- Application: Apply appropriate treatment to the weeds.

- Documentation: Record weed location and the applied treatment.

This presentation will discuss the current state of play for weed identification sensors and review recent results of site specific herbicide trials.

Weed identification

Presently, the only commercial weed sensors are spot spray systems that are only for use in fallow situations, where all green plants are considered weeds and sprayed, such as the WeedSeeker® and WEEDit systems. However, numerous groups around the world have been working on sensing systems that can identify different weed species within a growing crop, including several groups in Australia. There are however, no commercially available products yet.

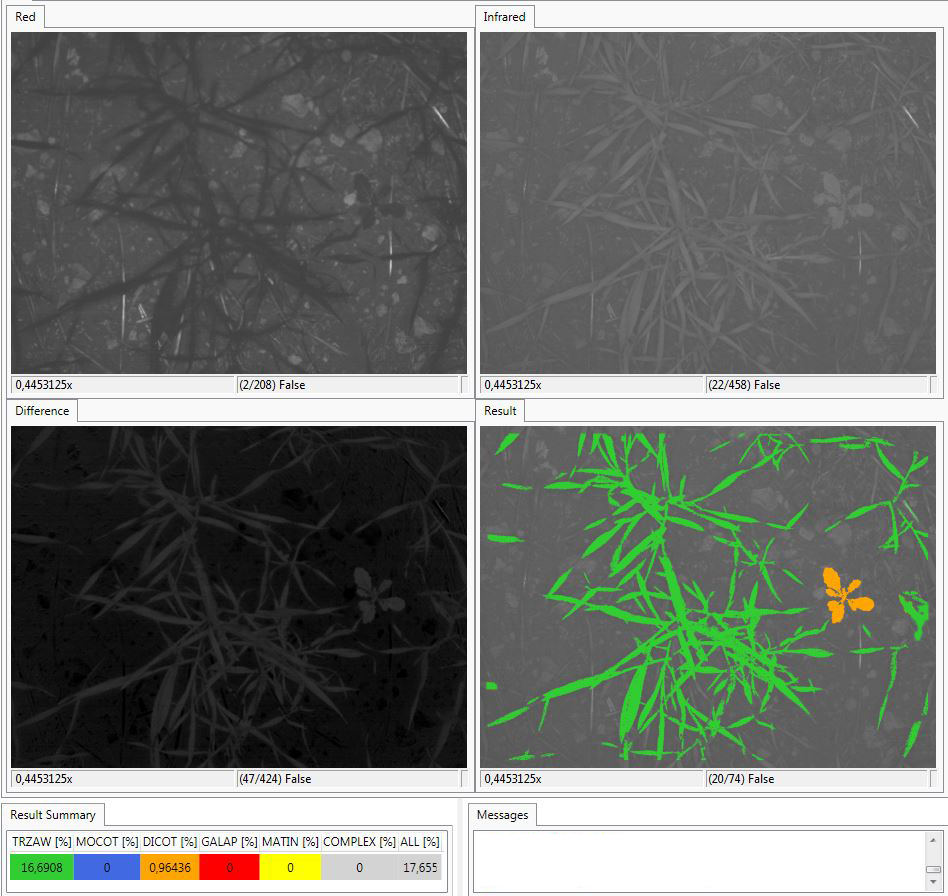

Agricon is a precision ag company in Germany that is developing and commercialising a weed ID sensor for the European market. This sensor uses near infrared and red imagery and leaf shape parameters to differentiate different weed types from crops. SAGIT is funding a project led by SPAA Precision Agriculture Australia to assess this weed ID sensor in Australian crops and to produce new adapted classifiers for identifying important Australian weeds in Australian crops. This includes all the grain legumes lentils, field peas, faba beans, chickpeas and lupins which are not typically grown in Germany. Examples of its application are discussed.

Figure 1: The H-Sensor mounted to the ute for mapping and collecting images of the crop and weeds.

Figure 2a (left): Wheat and an indian hedge mustard collected in the red and near infrared spectrum, and how the sensor has classified these differently. Figure 2b (right): Lentil and ryegrass collected in the red and near infrared spectrum, and how the sensor has classified these differently.

Variable rate herbicide application

The economic return from SSWM with herbicides can’t exceed the cost of the herbicide unless the herbicide has a phytotoxic effect on the crop and reduces yield. Therefore, when cost for weed mapping and variable rate application are considered, it is apparent that SSWM with low cost herbicides will not be economical.

In comparison, variable rate applications of pre-emergence herbicides in cereals are more economically viable, as these herbicides are typically more expensive. The herbicide savings are dependent on infestation level, but in one paddock where 35 per cent of the paddock was weed infested, variable rate application targeting Boxer Gold® to the high density patch and trifluralin to the low density patch would have generated a saving of $15.30/ha.

Variable rate applications reduced the risk of low returns from using high cost herbicides across the whole paddock.

Variable rate application made it economical to treat smaller patches. To make an economic return in the year of application with a uniform high cost treatment (e.g. Boxer Gold®) required at least 11 per cent of the paddock to have a high density ryegrass patch. With variable rate application it was economic to treat patches less than 6 per cent of paddock area. This assumes $7.50/ha for uniform rate application costs and $15/ha for variable rate application costs.

Across a number of paddocks in the 'high' density weed patches the highest efficacy treatments were also generally a higher cost, being greater than $25/ha in all cases. In high weed densities these higher costs were returned through increased yields. The exception was where the herbicides caused phytotoxic effects on the crop. The benefit of high efficacy treatments at high density weed sites was often observed in subsequent years with reduced seedling recruitment in following years. However due to the high background seed bank associated with the high density patches the populations were still elevated and required ongoing targeted management with high efficacy treatments to deplete the seed bank further. Where herbicide application was reduced at low density weed sites it was important to continue monitoring these sites for any population increase in subsequent seasons and treat where necessary. Improved weed detection systems will facilitate annual surveillance of weed patches and their change over seasons.

Variable rate seed

In addition to varying herbicides, crop seed rates can also be varied. Increased seed rates in the weed patch are used to increase crop competition and reduce weed vigour. This is generally simpler to apply than variable rate herbicide, too.

Variable rate herbicide to soil type

Several soil applied residual herbicides make label statements indicating different label rates for different soil types, with different soil types often defined by soil texture and organic matter levels. This information could form the basis for variable rate applications of herbicide based on soil type, with data layers such as EM38 potentially being suitable for defining soil types. The advent of ‘on-the-go’ pH sensors might also provide useful information for producing soil maps of herbicidal activity. While some growers may manually change rates ‘on-the-go’ according to their assessment of soil type change, there are few examples of this process being automated and used widely.

Application

Herbicide application can be targeted site specifically by varying the rate of a single tank mix with high and low doses targeted to different zones, or with multiple products being turned on and off independently. Varying rates of a single tank mix is the simplest application and can be achieved with current boom spray technology without modification. Varying the rate of a tank mix is achieved by changing the overall application volume, and therefore, the range of rates that can be achieved will be limited by nozzle selection, pressure and targeted spray quality. A greater range of rates can be achieved by decreasing ground speed where application volume increases. However, this may be problematic in practice. Nozzle technology such as pulse width modulation (Aim Command) allows a much greater range of application volume independent of ground speed and spray quality.

To target different herbicide products to different zones is more difficult. With current boom spray technology and a single tank mixture, this requires different herbicide products to be applied in separate applications. To achieve independent control of different herbicide products in one pass requires the use of direct injection systems or carrying two separate tanks at the same time that contain different products and are applied through two separate boom lines.

Conclusion

High density weed patches should be targeted with high efficacy treatments over several seasons to drive weed numbers down. Herbicide savings can be made by reducing inputs into low density populations and these savings are greatest when using high cost herbicides. It is important to monitor weed populations where herbicide application has been reduced for density increase and be prepared to treat where large increases occur. Improved weed mapping systems and an annual weed surveillance program will help to ensure population increases are monitored and managed.

Acknowledgements

Funding from SAGIT is gratefully acknowledged for supporting this research.

Contact details

Sam Trengove

PO Box 6, Bute, SA, 5560

0428 262 057

samtrenny34@hotmail.com

@TrengoveSam

Was this page helpful?

YOUR FEEDBACK