Real time soil tests in the field? Science fiction or just over the horizon

Author: Mike McLaughlin, José M. Soriano Disla, Les Janik and Mohsen Fruzangohar (CSIRO Land and Water, Waite Campus, Urrbrae, SA), Michael Zerner (University of Adelaide), Sean Mason (Agronomy Solutions, Magill 5072), | Date: 26 Feb 2018

Key messages

- New hand-held and miniature infrared instruments have great promise for use in predicting soil properties in situ in the field.

- Generally, instrument performance is a case of ‘you pay for what you get’ — the cheapest instruments were the least useful for predicting soil properties, due to the restricted spectral ranges of these instruments.

- Integration of infrared spectroscopy sensors into commercial soil sampling equipment could offer significant opportunities to reduce the costs of assessment across paddocks and down the profile, improving precision management of soils and subsoils.

- Two real time examples of specific soil (PBI) and plant (crop N content) measurements taken by IR in the field outline the potential of IR technology.

Aims

Soil analysis is slowly moving from the complex laboratory physical and chemical analytical procedures to the field by adapting rapid and simple spectroscopic methods. Recent developments in spectroscopic instrumentation have reduced the cost and size of instruments, with the newest and cheapest instruments costing only a few hundred dollars. The falling cost of instrumentation opens up opportunities for growers, consultants and soil sampling contractors to consider either hand-held use of instruments for soil analysis in the field, or for integration of smaller instruments into commercial soil testing equipment. This could speed up assessment of soil both across paddocks as well as down the profile to characterise subsoil constraints to grain crop production.

The most common spectroscopic method used to measure multiple soil properties is infrared (IR) spectroscopy, using either the near or mid infrared wavelengths (NIR and MIR) (Soriano-Disla et al., 2014). Several new low-cost, portable IR spectrometers are now available off-the-shelf. It is vitally important that these spectrometers are sufficiently tested for performance before they become common tools used by advisors in a field scenario.

Method

This article outlines results from a survey of spectrometer performance in assessing a range of soil properties using over 400 soil samples encompassing the major soil orders used for agriculture in Australia. We have also outlined two specific examples of how IR can be used in field to determine two important soil and plant parameters 1) Assessment of PBI values across a paddock landscape and 2) determination of crop N content in season.

Results

Spectrometer comparison

Soil samples were scanned with five hand-held or miniature IR probes and compared with scans from a laboratory instrument. Multivariate prediction models for a number of key soil properties were developed for each of the soils as follows:

- Extractable boron (B).

- Exchangeable bases, Ca2+, Mg2+, K+, Na+.

- Cation exchange capacity (CEC).

- Air-dry moisture (ADM) content.

- Electrical conductivity (EC).

- pH.

- Chloride.

- Organic carbon (C).

- Particle size distribution (sand, silt, clay).

- Bulk density (BD).

- Drained upper limit (DUL) (0.1 BAR) moisture.

- Lower limit (15 BAR) (LL15) moisture.

- Saturated Moisture (SAT).

The instruments tested are detailed in Table 1.

The best (R2 values above 0.70) predictions (relationship between measured and predicted soil property) were obtained for total and organic C and nitrogen (N), pH, CEC, exchangeable sodium percentage (ESP), clay/sand, exchangeable Ca, magnesium (Mg) and sodium (Na), and DUL and LL15.

The two best performing IR devices were the UV-Vis-NIR device (SM-3500 OreXpress by Spectral Evolution, MA, USA) and the handheld MIR device (4100 ExoScan by Agilent A2 Technologies, CA, USA) (Figure 1).

Table 1. Infrared instruments and main features — note the Frontier instrument is the non-portable laboratory ’benchmark’ instrument.

Instrument | Frontier | ExoScan | FlexScan | SM-3500 | NIRscan | SCiO1 |

|---|---|---|---|---|---|---|

Brand | Perkin Elmer | Agilent | Agilent | Spectral Evolution | Texas instruments | SCiO |

Spectral range | 7800-370 | 6000-650 | 6000-650 | 350-2500 | 900-1700 | 740-1070 |

Used range | 4000-450 | 4000-750 | 4000-750 | 400-2450 | 950-1650 | 740-1000 |

Scanning time | 15 s | 15 s | 15 s | 30 scans | 30 scans | 1.5 s |

Weight | 34kg | 3.2kg | 3.4kg | 4kg | 100g | 35g |

Size | 520x600x300 | 171 x 119 x 224 mm | 340×220×160 mm | 216x305x89 | 62x58x36 | 19x40x68 |

Portability | Bench-top | Hand-held | Hand-held - cord | Hand-held - fibre cable | Miniature | Miniature |

Back freq | 60 m | 60 m | 60 m | 30 m | 30 m | 5 m |

Sample | Manual holder | Stainless cups | Stainless cups | Petri dish | Glass vials | Petri dish |

Price | ~$80,000 | ~$60,000 | ~$60,000 | ~$80,000 | ~$1,000 | <$1,000 |

1Due to poor performance and technical issues, only n = 215 samples scanned

2Standard normal variate

Compared across all soil property predictions, the cheaper instruments performed poorly overall (Table 2).

Table 2. Median R2 over all soil analyses (relationship between predicted and measured soil properties) for each instrument.

Instrument | R2 |

|---|---|

ExoScan | 0.73 |

FlexScan | 0.73 |

Frontier | 0.70 |

SM-3500 full range | 0.66 |

NirScan | 0.49 |

SM-3500 (NirScan range) | 0.48 |

SM-3500 (SCiO range) | 0.42 |

SCiO | 0.22 |

In field case studies

PBI

PBI is an important soil characteristic describing P mobility which drives P fertility, P fertiliser reactions and is crucial in defining critical levels of Colwell P (Moody 2007). The main soil parameters that influence PBI values and generate higher fixation of added P inputs are calcium carbonate, and iron/aluminium oxides. These soil characteristics can change rapidly across soil landscapes which influences the resulting soil PBI. Therefore, a technique which enables rapid and cheap analysis of PBI across a paddock would potentially add great value to variable rate technology by focusing P inputs where P fertiliser efficiencies are low.

Mid-Infrared technology (MIR) has been shown to accurately determine the concentrations or proportions of major soil properties that influence the soil’s ability to retain P. MIR-predicted P buffering values have been shown to be strongly related to PBI measurements across a large range of PBI values (Forrester et al. 2014). Handheld MIR potentially allows for the generation of paddock PBI maps but the influence of field conditions on MIR-PBI predictions has yet to be tested.

An assessment of the ability of MIR technology to be able to map PBI across a paddock was performed at a focus paddock near Karoonda, South Australia which had a typical dune swale system and varying PBI values. Samples were taken in a grid format (120m x 60m) after significant rainfall events and therefore the effect of soil wetness on the MIR determination of PBI could be evaluated (wet soil is particularly problematic for MIR analysis of soils). The soil sampling methodology involved taking 2 cores to a depth of 0-10 cm in a concentrated area. The soil cores were directly scanned by a hand held ExoScan MIR instrument to obtain spectra from intact field cores. Cores were also combined, mixed and rescanned with the MIR (Field – homogenised). The composite soil sample was then bagged and brought back to the laboratory for further analysis. On reaching the laboratory, the sample was dried and sieved (< 2 mm) and fine ground (< 150 µm). MIR spectra were again obtained on the laboratory-processed samples in addition to the chemical PBI determination in the laboratory. Partial least square regression (PLSR) models were derived from the MIR spectra and reference data.

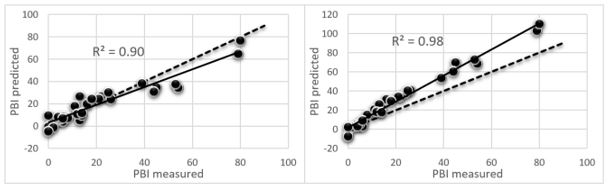

Using a site-specific calibration model developed from a subset of the Karoonda samples, PBI values were predicted for all samples with high accuracy (R2 = 0.9, Figure 1). There was a strong relationship between PBI and soil moisture content at this site (R2= 0.9). Thus, an additional model was built from a combination of MIR spectral information plus soil moisture as the independent input variables, obtaining an even better and very accurate model for predicting PBI (R2 = 0.98, Figure 1). These results confirmed the excellent potential of the hand-held MIR spectrometer for the prediction of PBI values in soils from a specific site, using both a site-specific and a global model. Similar highly accurate models have been developed across P response trials at four other locations.

Figure 1. Site-specific validation of PBI values from Exoscan spectra of field-moist Karoonda soils versus laboratory determined PBI. PLSR calibration models derived from only PBI data and MIR spectra (left), and PBI data and MIR spectra plus soil moisture contents (right).

Crop N content

In-season nitrogen applications can be a highly efficient method of meeting crop N requirements if seasonal conditions are favourable. Decisions around the timing of N applications can be made based on numerous factors including follow up rain, current crop N content and predicted yield potentials. In some cases, these assessments need to be made quickly and therefore the time delay involved with sending crop samples off to a laboratory for N analysis might be costly. Rapid analysis of current crop N status in situ could potentially alleviate these pressures.

Two small plot N response trials assessing effects of two different times of sowing on utilisation of N inputs on a rage of wheat varieties were used to determine the capabilities of NIR to predict crop N contents in field environments. These plot trials were located at Mintaro, in the Mid-North region of S.A. Plots were scanned using a NIR instrument (FieldSpec Handheld Spectroradiometer) at a height of approximately 0.5 metres similar to the method that Greenseekers™ use to scan vegetative growth. Plots were scanned at early and late reproductive growth stages. Samples of crop from each plot were taken and brought back to the laboratory where they were dried and ground. Processed samples were then scanned by portable NIR instruments. in addition to a benchtop MIR/NIR (Perkin-Elmer Frontier FTIR) instrument followed by traditional laboratory analysis to determine total N contents. PLSR) models were derived from the NIR/MIR spectra and reference data.

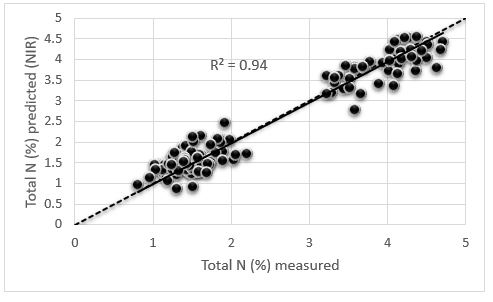

Initial cross validation models for in-field assessment of wheat N content, using portable NIR, are promising (Figure 2). Data across all sowing times and growth stages was combined and high coefficients of determination (R2 = 0.94) were obtained between measured and predicted crop total N contents. It appears that scans on the earlier vegetative stage (GS31) are more accurate compared to the flowering growth stage, but interestingly, the two different growth stages appear to sit in the same regression line.

Figure 2. Cross validation of measured total N crop values with predicted crop N contents using portable NIR in field spectrometer.

Conclusion

Current prices of suitable handheld IR spectrometers restrict the uptake of the technology for use in the field. With the assumption that prices will decrease due to competition and advancement of IR technology it is important that quality control measures from the laboratory are transferred to field use. It is also recommended that instrument performance in the field is continually benchmarked against the laboratory methods which are the industry standards. Accurate performance of IR is largely dependent on the number and variety of previously analysed soil samples that form calibration models allowing predictions to be performed. The greater the number of soil samples, and the greater the heterogeneity of soils, built into the models the more powerful IR becomes. Skills associated with software management, spectral interpretations and regression analysis are also required.

Acknowledgments

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC — the authors would like to thank them for their continued support. The authors also wish to acknowledge Dr Ed Barrett-Lennard (Department of Agriculture and Food WA) for the supply of intact soil cores.

GRDC Project Number: CSO00020

GRDC Project Code: CSO00020,

Was this page helpful?

YOUR FEEDBACK