Looking inside Grainbags

Author: Aidan Sinnott, SEPWA | Date: 25 Jan 2019

Key Messages

- Use of grainbags across WA is on the increase to assist in harvest logistics

- Anecdotal quality issues in malt barley attributed to grainbag storage is yet unproved

- Industry buyers of malt barley hesitant to purchase malt barley stored in grainbags

- Very little data available regarding inside bag conditions

- Data so far suggests that quality of wheat and barley is not affected when stored in grainbags in the short term

Aims

There has been a lot of conjecture in the agriculture industry relating to grain which has been stored in bags for extended periods of time. SEPWA is nearing the end of an 18-month project to investigate grain quality factors (moisture, temperature, germination, colour) and market liability risks associated with the use of silo bags in the WA grain export supply chain.

In the past 5 years the use rate of grain silo bags in the WA grain industry has increased dramatically. The key driver for this is the logistical advantage of rapid harvest followed by on site storage of grain. Farmers have found their use to be vital in areas such as moisture and grain quality management as well as potentially capturing freight cost advantages. Grain silo bags are now a proven tool for harvest management in WA – and particularly in the Esperance region.

There is however a gap in local technical data on their best practice guidelines and potential grain quality risk factors. In a pro-active approach to a potentially negative market response and to ensure maximum on farm supply chain flexibility, SEPWA members asked to conduct a research project to assess potential effects on grain quality associated with silo bags to highlight ways to minimize risk going forward.

This project has closely monitored numerous grain bags during the 2017/18 and 2018/19 harvest seasons to assess them for grain quality implications. In this process, the logistical and harvest management implications have been documented to understand best practice guidelines for all WA grain growers.

Method

SEPWA gained access to eight silo bags in total in 2017-18, seven of which were barley and one wheat. Two barley bags were located within the Salmon Gums area; two north of Rollond Road, between Field Road and Neds Corner Road. Another two barley bags and a wheat bag were located west of Cascade; and the final bag north east of the Munglinup area. The spread of silo bags across the region was deemed to be important due to the variety of climatic conditions between these areas.

The bags were laid on different dates, however SEPWA staff were at the location within a week, taking the first sample. Sampling method followed CBH parameters/ protocol for grain stored in bags. CBH provided SEPWA with a grain spear for the trial work. After the initial round of sampling, it was decided that the measurements of temperature required more rigorous analysis and SEPWA purchased Tinytags to monitor the temperature inside and outside the bag. A Tinytag was placed under shade on a star picket beside the bag, and a probe with two Tinytags set at 30cm and 120cm was inserted into the silo bag. The loggers measured and recorded temperature every 20 minutes for the duration of the grain being in the bag. Conditions inside silo bags are generally not well understood, with little data available.

Results

The effects of ambient temperature over summertime could be expected to play a large part in grain temperature within the silo bag, but the data collected over the course of the trial shows that the effects are minimal.

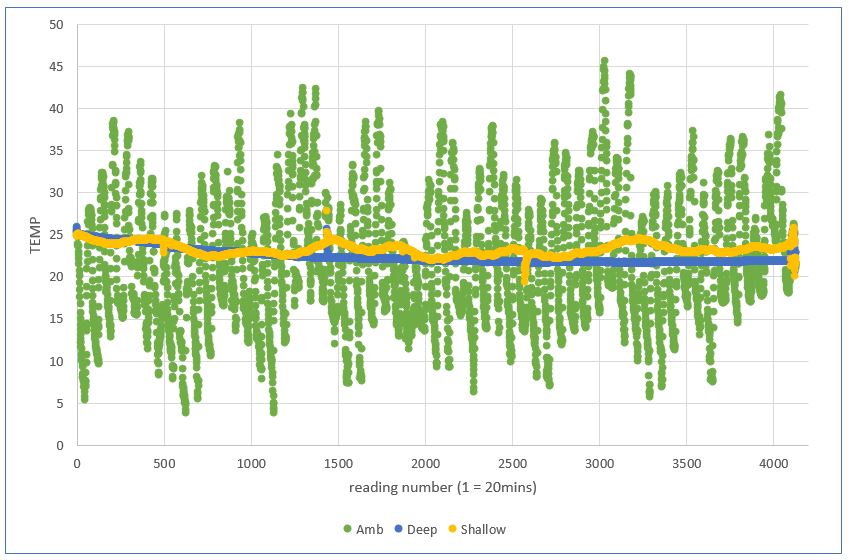

The graph in Figure 1 shows the ambient temperature over 71 days (green points), temperature on the shallow depth (yellow), and temperature at deep depth (blue). The data shown here was collected on a bag located west of Salmon Gums from the 22nd of November through to the 18th January. From when the sensors were installed, the grain temperature decreased over time, and particularly at depth within the silo bag. The variety was LaTrobe which was put in the bag at 11.9% moisture.

Figure 1: Ambient temperature, shallow and deep grain bag readings over 74 days.

The shallow temperature fluctuated with ambient temperature relative to the deep temperature. Interestingly while there were 6 days during this period with temperatures exceeding 40 degrees, there were also 6 nights which were around 5 degrees. Overall the ambient temperature was 66.9% of the time lower than the grain temperature within the bag.

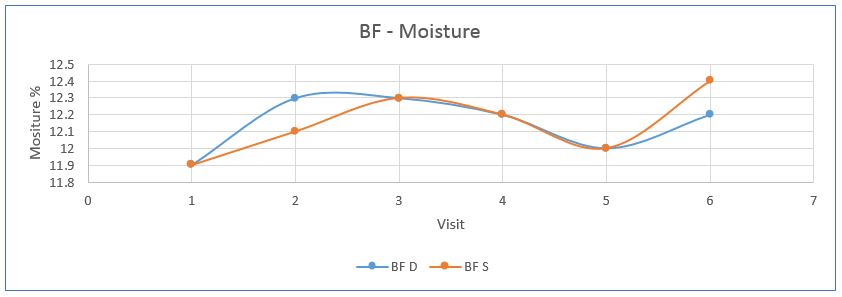

Figure 2: Moisture readings at Boomerang Farms over 74 days

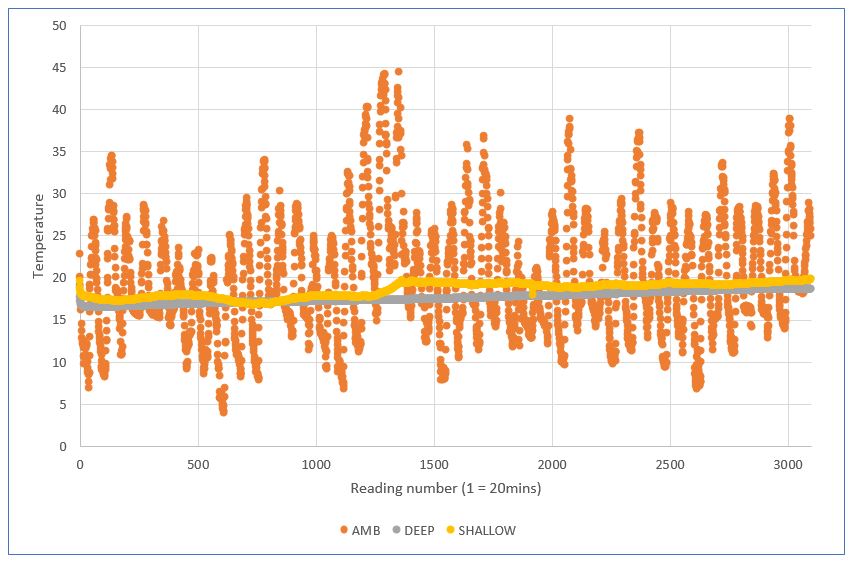

The pattern in Figure 2 was generally the case in most of the silo bags, with the exception being the bag at Munglinup (as shown in Figure 4). The ambient temperature is shown by the orange points, shallow is the yellow dots, and the deep is the grey dots.

Once temperature of the loggers had normalized, the grain within the bag was warming up over the course of the 43 days the bag was monitored. There is a relatively sharp increase around day 18, which followed 3 days where ambient temperatures were over 40 degrees. When the bags were emptied, the temperature of the grain was still below 20 degrees. The variety in the bag was LaTrobe, and went in at 13.5% moisture. At the end of the trial, the moisture was recorded as 14%. The average ambient temperature over the trial at this location was 19.7 degrees.

Figure 3: Ambient temperature along with deep and shallow grain bag readings at Munglinup

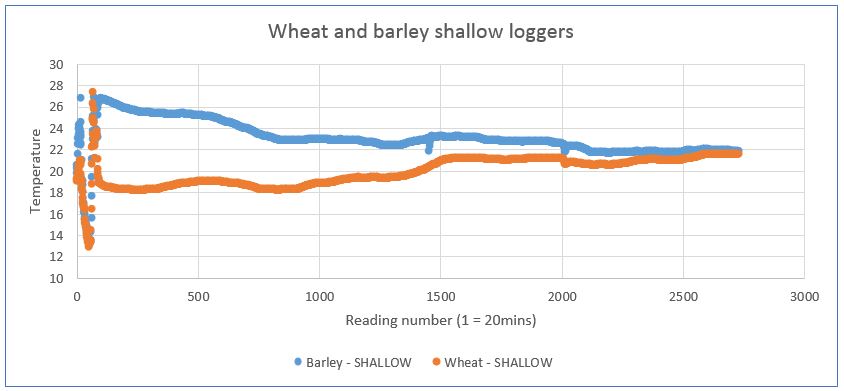

Interestingly when comparing wheat and barley bags in similar locations, in this case at Cascade, it appears that wheat grain has a much lower temperature than that of barley. This is illustrated in the conditions once temperature loggers were inserted into a bag of Mace (moisture 13.3%) and LaTrobe (moisture 10.3%). Both bags were under very similar weather conditions due to their proximity. The average ambient temperature at both sites was 19.9 degrees over 38 days. From the measurements it appears that the wheat is heating up and the barley is cooling down to get to the average ambient temperature.

Figure 4: Wheat and barley shallow temperature readings in bags in close proximity (<10km)

Finally, the main purpose was to assess the germination of barley post storage in bags, and to do that, CBH ran germination tests on the initial samples and final samples from the trial:

Initial sample (%) | Final sample (%) | Days in bag | |

|---|---|---|---|

Salmon Gums North (MASG) | 100 | 100 | 32 |

Salmon Gums West (BF) | 100 | 100 | 74 |

Cascade (MR) | 100 | 100 | 61 |

Munglinup (MA) | 99 | 100 | 60 |

Figure 5 : Germination results of barley stored in bags over time

Conclusion

Overall it appears that there would be very little or no effect on germination percentage under the conditions looked at over harvest 2017 and 2018. Further work is being conducted in the post 2018 harvest, grainbags are under scrutiny for longer periods of time, i.e. storage periods of over 3 months.

Acknowledgments

Many thanks to the growers who were involved; Gerard and Terry Antonio, Murray Ayers, Mark Walters, Mark Roberts, and Gary Walters, great to work with you. Also, thanks to Kim Thornton and Renee Dowsett at CBH Chadwick for lending SEPWA a grain spear, allowing access to an Infratec, and organising germination tests on samples at the laboratory.

GRDC Project Number: 9176003

GRDC Project Code: 9176003,

Was this page helpful?

YOUR FEEDBACK