National Paddock Survey – closing the ‘yield gap’ and informing decisions

Take home messages

(from work undertaken on eight paddocks on the Yorke Peninsula 2015 to 2018)

- Intensive monitoring of soils and crops over a rotation sequence has identified why crops do not achieve their potential yield.

- Reviewing paddock performance at the end of the season and using paddock records is essential for sustained improvement in agronomic performance.

- Insufficient nitrogen (N) was the main cause for the yield gap in National Paddock Survey (NPS) paddocks on five Yorke Peninsula monitored paddocks. Frost and heat shock were also responsible for significant yield penalties. Diseases, weeds and insects also contributed, but were less severe in impact.

- Three paddocks on the Yorke Peninsula achieved significantly higher yields than could be explained by either simulation modelling or WUE. The reasons are not clear and will be further investigated (no other paddocks in the 250-paddock data set have shown a similar result). A suggested explanation is access to deep soil water.

Background

The yield gap is the term applied to the difference between achieved and potential yield, where potential yield is estimated from simulation models. On average, Australia’s wheat growers are currently achieving about half their water-limited potential yield (Hochman et al. 2016, Hochman and Horan, 2018). Previous research with individual growers in the Wimmera/Mallee in Victoria determined that the long-term yield gap for those growers was approximately 20% (van Rees et al. 2012). See here for a National overview of the yield gap.

National Paddock Survey is a four-year (2015 to 2018) GRDC-supported project designed to quantify the yield gap on 250 paddocks nationally and to determine the causes for the yield gap. Additionally, its aim is to establish whether management practices can be developed to reduce the yield gap to benefit farm profitability and to provide growers and their advisers with information and the tools required to close the yield gap.

Method

Two hundred and fifty paddocks nationally, 80 in each of WA and northern NSW/Qld, and 90 in southern NSW, Vic and SA, were monitored intensively over a four-year rotation (2015 to 2018). Consultants and Farming Systems groups undertook the monitoring. Two zones in each paddock were monitored at five geo-referenced monitoring points along a permanent 200m to 250m transect. Each monitoring point was visited four times per season (pre- and post-season soil sampling and in-crop at the equivalent crop growth stages (GS)of GS30 and GS65). Yield map data was obtained for each paddock which enabled the yield of each zone to be determined accurately. Table 1 lists the annual monitoring undertaken in each zone.

All paddocks were simulated with the Agricultural Production Systems sIMulator (APSIM) (Holzworth et al. 2014) and during the season, Yield Prophet® was available to all consultants and growers.

The whole data set (four years x 500 paddock zones) is being analysed by Roger Lawes, CSIRO for factors primarily responsible for the yield gap in each of the three GRDC regions (Lawes et al. 2018).

This paper outlines the results of eight paddocks from one consultant, Stefan Schmitt, working on the Yorke Peninsula, SA. The results are discussed as a paddock specific yield gap analysis over four seasons focused on outcomes for the grower and consultant.

Results are presented as the modelled APSIM simulations in which:

- Ya = Actual Yield (as determined for each zone from yield map data).

- Ysim = Simulated Yield (for the same conditions as those in which the crop was grown).

- Yw= Simulated water limited, N unlimited yield (for the same conditions as those in which the crop was grown, but with N supply unlimited). Yw is considered the potential yield for the crop.

- The Yield Gap is calculated as the % difference between Yw and Ya ((Yw-Ya)/Yw).

Note: APSIM currently accurately simulates wheat, barley and canola. No attempt was made to simulate the other crop types grown (lentils, faba beans, chickpeas, vetch, field peas).

Table 1. Overview of monitoring and data collected per zone for each NPS paddock.

Monitoring | Timing | Monitoring | Timing |

|---|---|---|---|

Deep soil test 4 depths (0-100cm) | Pre-sow | Paddock yield and yield map data | Post-harv |

Predicta®B (0-10cm) | Pre-sow | Crop density, weeds, foliar diseases, insects (/m2) | GS30 |

Deep soil test 4 depths (0-100cm) | Post-harv | Cereal root sample to CSIRO | GS30 |

Crop and Cultivar | Weeds, foliar diseases, insects /m2) | GS65 | |

Sowing date and rate | Cereal stubble/crown for Fusarium | Post harv | |

Fertiliser, herbicide type, rate, date | General observations | ||

Temp buttons (1 per paddock) | GS60-79 |

Data was entered via the NPS website and stored in a purpose-built structured query language (SQL) Server database.

Results and discussion

Annual individual paddock results

Data from three paddocks on the Yorke Peninsula are presented as examples of outputs as informed by the paddock monitoring.

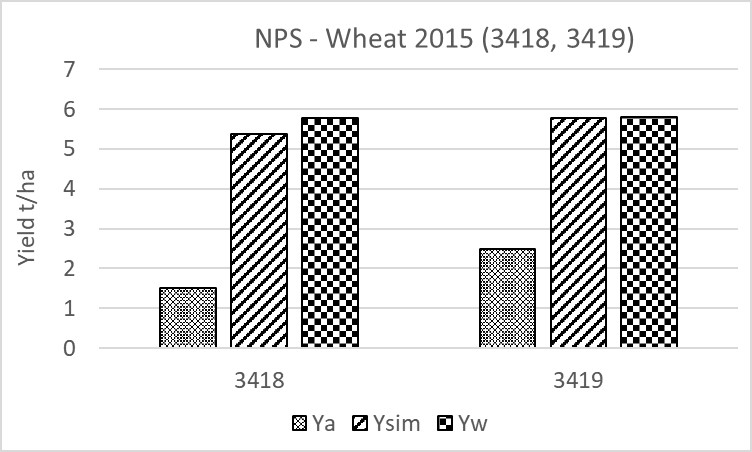

- Example 1: Paddock yield (Ya) was lower than the simulated yield (where Ysim = Yw) (Figure 1).

Paddock on Yorke Peninsula 2015 (zone A – 3418, sandy loam; Zone B – 3419, clay loam). Ya=Actual yield; Ysim=Simulated yield; Yw=Water limited (potential) yield. | Paddock and crop information specific to 2015. Note - nd is ‘not detected’ |

| N available: 169 & 201kg/ha (A&B) Water avail: 271 & 277mm (A&B) Soil disease – Predicta®B: nd Root health GS30: Moderate Stubble disease: nd In-crop disease GS65: nd Weeds GS65: Zone A – Ryegr 1 /m2; Insects GS65: Zone A: Luc flea 8 /m2, RWA 5 /m2 Zone B: Luc flea 96 /m2 Frost (GS60 to 79): 2 days 0 to -2oC Heat shock (GS60 to 79): nd |

Figure 1. Data from example paddock 1 monitored according to the NPS project (Table 1).

Interpretation

Crop 2014: lentils (1.8t/ha).

Wheat in 2015: had a simulated yield equal to the potential yield (Ysim = Yw), which is a strong indication that the crop is not N limited. This is supported by the N available to the crop (soil test results plus N fertiliser application of 169kg N/ha and 201kg N/ha for Zone A and B respectively).

The simulated yield was much higher than the actual yield (Ysim > Ya) which indicates there were factors limiting production. The crop did not have measurable disease, weed or insect problems. The main factor contributing to the loss in yield appears to be frost damage caused by two nights of temperatures between 0oC and -2oC during GS60 to GS79.

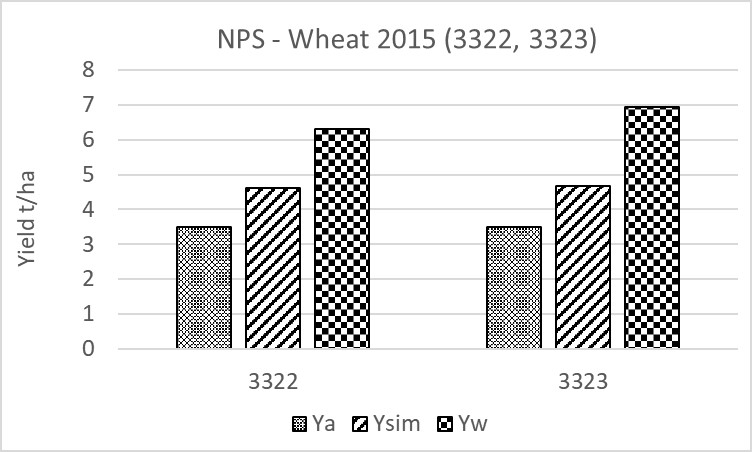

- Example 2: Paddock yield (Ya) was lower than the simulated yield (Ysim) which in turn was lower than the potential yield (Yw) (Figure 2).

Paddock on Yorke Peninsula 2015 (zone A – 3322, sandy loam; Zone B – 3323, clay loam). Ya=Actual yield; Ysim=simulated yield; Yw=water limited (potential) yield. | Paddock and crop information specific to 2015. |

| N available: 163 & 167kg/ha (A&B) Water avail: 251 & 311mm (A&B) Soil disease Predicta®B: Fusarium and Pythium High (A&B), YLS High (A) Root health GS30: Moderate Stubble disease: Fusarium 60% of stems (A&B) In-crop disease GS65: nd Weeds GS65: Zone A – W. oats 2 /m2; Insects GS65: Zone A: nd Zone B: Snails 42 /m2 Frost: 1 day 0 to -2oC (GS60 to 79) Heat shock: 2 days 32 to 34oC |

Figure 2. Data from example paddock 2 monitored according to the NPS project (Table 1).

Interpretation

Crop 2014: wheat (5.3t/ha).

Wheat in 2015: simulated yield lower than the potential yield indicates that N was limited. This is supported by relatively low available N for a potential yield of between 6t/ha and 7t/ha (soil N at sowing + fertiliser N of 163kg/ha and 167kg/ha for Zones A and B, respectively). A common rule of thumb is that 40kg N is required per tonne of production, which corresponds well with the achieved yield of approximately 3.5t/ha. The simulated yield was higher than the actual yield (Ysim > Ya) by approximately 1t/ha, which indicates other factors were limiting production. The crop in 2015 was wheat on wheat. Soil disease levels as assessed through the Predicta®B soil test was high for Fusarium and Pythium in both zones; Zone A also had high levels of soil DNA for yellow leaf spot (YLS). Fusarium was detected post-harvest in the stubble. Weeds and insects (including snails) were present but were at relatively low levels and are unlikely to have had a yield impact. Frost (0 oC to -2oC) occurred on one night and heat shock of 32 oC to 34oC on two days between GS60 and GS79 may also have contributed to the loss in potential yield.

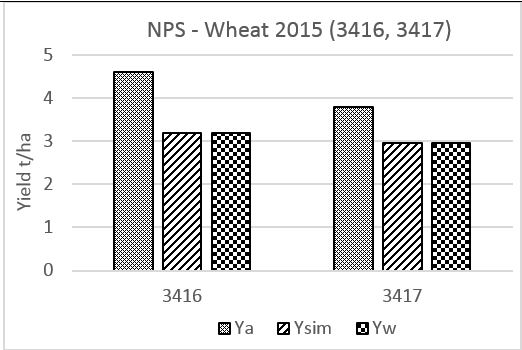

- Example 3: Paddock yield (Ya) is significantly higher than the simulated yields (Ysim and Yw) (Figure 3).

Paddock on Yorke Peninsula 2015 (zone A – 3416, sandy loam; Zone B – 3417, clay loam). Ya=Actual yield; Ysim=Simulated yield; Yw=Water limited (potential) yield. | Paddock and crop information specific to 2015. |

| N available: 251 & 289kg/ha (A&B) Water available: 179 & 172mm (A&B) Feature: chicken manure applied at 2.5t/ha every 3 to 4 years. Soil disease – Predicta®B: nd Root health score GS30: Moderate Stubble: Fusarium (16% of stems) In-crop disease GS65: nd Weeds GS65: Zone A – Ryegr. 28 /m2; Insects GS65: nd Frost: nd Heat shock: nd |

Figure 3. Data from example paddock 3 monitored according to the NPS project (Table 1).

Interpretation

Crop 2014: lentils (1.2t/ha).

Wheat in 2015: the simulated and potential yield were the same (Ysim = Yw) in both zones, which indicates the crop was not N limited. However, Ya > (Ysim = Yw) which indicates a cause for the crop to perform better than the simulations (Note: water use efficiency (WUE) of crops grown in these three paddocks is also substantially higher than the current potential of 22kg/mm/ha – hence it is unlikely to be a simulation aberration). There are only three paddocks in the NPS database which show this trend consistently over the four years of the project. All three paddocks received regular applications of chicken manure and all three responded with substantially higher yields than simulated (the three paddocks are on the same farm). Using simulation, it was determined that an additional 80mm of plant available water (PAW) was required to achieve a simulated yield equal to the actual yield. It is possible that manure is changing the plant available water holding capacity of the soil. However, we could not determine any changes in soil water holding capacity through the measurements undertaken. The crop may be accessing water from deeper down the profile. It is also possible the manure is releasing carbon dioxide (CO2) which is enhancing crop growth. The crop was modelled with an additional 50ppm CO2 (from 400ppm CO2 to 450ppm CO2), but this made very little difference in the simulated yield (increase in yield of approximately 50kg/ha).

Results of four years of monitoring on the Yorke Peninsula

The results of the monitoring for all eight paddocks on the Yorke Peninsula are presented in Table 2 (note: the table does not contain all the results of the monitoring).

The primary reasons for the yield gap are:

- Insufficient N for 10 of the 34 wheat paddocks in the rotation where Yw > Ysim.

- Predicta®B is a good indicator of likelihood for a yield penalty, especially for Fusarium.

- Frost and heat shock negatively affect yield potential.

Weeds and insects on these paddocks had little impact on yield.

Good paddock monitoring records are essential for identification of factors leading to a yield penalty. The interpretation and improvement of individual crop yields, as revealed by the yield gap analysis using simulation modelling, requires further consideration of the yield-determining factors and we need to continue to improve our understanding of these factors and especially the interactions between them.

Table 2. Four years of monitoring on eight paddocks on the Yorke Peninsula - SA(Note: paddocks 3418/19, 3322/23 and 3416/17 were used in Examples 1 to 3 above)

NPS | Crop type | Ya | Ysim | Yw | Ygap % | WUE | Avail. N | Avail. water | Predicta®B | Disease Roots GS30 | Fusarium stubble | Disease In crop GS65 | Weeds GS65 / m2 | Insects GDS65 /m2 | Heat days > 34o GS60-79 | Frost days 0 to -2o GS60-79 | Frost days < -2o GS60-79 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

3046 | 2015 | Barley | 4.1 | 2.1 | 6.3 | 35 | 16 | 91 | 243 | YLS high | Low | Brome3 | 0 | 0 | 0 | ||||||||||

2016 | Lentils | 3.2 | 0 | 0 | 0 | ||||||||||||||||||||

2017 | Wheat | 5.1 | 4.4 | 4.4 | -16 | 26 | 327 | 154 | nd | Mod | Sept. L | 0 | 0 | 0 | |||||||||||

2018 | Oats | Hay | |||||||||||||||||||||||

3047 | 2015 | Barley | 3.8 | 4.5 | 4.4 | 15 | 20 | 158 | 243 | YLS high | Low | NFNB L | 0 | 0 | 0 | ||||||||||

2016 | Lentils | 2.2 | Rye1 | 0 | 0 | 0 | |||||||||||||||||||

2017 | Wheat | 4.7 | 3.3 | 3.3 | -44 | 15 | 348 | 263 | nd | Low | Sept. L | 0 | 0 | 0 | |||||||||||

2018 | Oats | Hay | |||||||||||||||||||||||

3320 | 2015 | Wheat | 3.4 | 4.0 | 6.9 | 51 | 11 | 148 | 379 | Fus & Pyth. high | Mod | 34% | Brome1 | 0 | 2 | 0 | |||||||||

2016 | Lentils | 3.7 | 0 | 0 | 0 | ||||||||||||||||||||

2017 | Wheat | 7.4 | 7.4 | 7.4 | -1 | 17 | 280 | 513 | nd | Mod | 0 | 0 | 0 | ||||||||||||

2018 | Lentils | 2.6 | Brome2 | ||||||||||||||||||||||

3321 | 2015 | Wheat | 3.2 | 3.2 | 6.9 | 54 | 12 | 113 | 442 | Fus & Pyth. high | Mod | 69% | 0 | 2 | 0 | ||||||||||

2016 | Lentils | 3.5 | 0 | 0 | 0 | ||||||||||||||||||||

2017 | Wheat | 8.2 | 7.4 | 7.4 | -12 | 18 | 271 | 513 | nd | Mod | 0 | 0 | 0 | ||||||||||||

2018 | Lentils | 2.9 | |||||||||||||||||||||||

3322 | 2015 | Wheat | 3.5 | 4.6 | 6.3 | 45 | 14 | 163 | 349 | Fus & Pyth high, YLS mod | Mod | 60% | WO2 | 1 | 1 | 0 | |||||||||

2016 | Lentils | 3.7 | 0 | 0 | 0 | ||||||||||||||||||||

2017 | Wheat | 4.9 | 6.9 | 6.9 | 29 | 8 | 283 | 465 | nd | Mod | 20% | Snails15 | 0 | 0 | 0 | ||||||||||

2018 | Lentils | 2.3 | |||||||||||||||||||||||

3323 | 2015 | Wheat | 3.5 | 4.7 | 6.9 | 50 | 16 | 167 | 359 | Fus & Pyth high | Mod | 60% | Brome2 | Snails42 | 1 | 1 | 0 | ||||||||

2016 | Lentils | 3.6 | 0 | 0 | 0 | ||||||||||||||||||||

2017 | Wheat | 6.4 | 5.9 | 6.9 | 8 | 14 | 232 | 698 | nd | Mod | 20% | Rye1 | 0 | 0 | 0 | ||||||||||

2018 | Lentils | 2.1 | Snails5 | ||||||||||||||||||||||

3348 | 2015 | Wheat | 4.0 | 4.1 | 5.0 | 21 | 18 | 121 | 285 | Rhizoc&YLS mod Pyth high | Rhizo | 6 | no data | no data | |||||||||||

2016 | Lentils | 1.6 | 71 | Rye19 | 0 | 0 | 0 | ||||||||||||||||||

2017 | Lentils | 1.2 | 2.7 | 2.7 | 56 | 0 | 0 | 0 | |||||||||||||||||

2018 | Wheat | 2.7 | 3.2 | 103 | 366 | nd | |||||||||||||||||||

3349 | 2015 | Wheat | 4.0 | 4.4 | 4.4 | 10 | 19 | 169 | 322 | Rhizoc mod | Rye18 | 6 | no data | no data | |||||||||||

2016 | Lentils | 1.6 | Rye6 | 0 | 0 | 0 | |||||||||||||||||||

2017 | Lentils | 1.1 | Rye13 | 0 | 0 | 0 | |||||||||||||||||||

2018 | Wheat | 1.7 | 1.7 | 174 | 378 | nd | |||||||||||||||||||

NPS | Crop type | Ya | Ysim | Yw | Ygap % | WUE | Avail. N | Avail. water | Predicta®B | Disease Roots GS30 | Disease stubble | Disease In crop GS65 | Weeds GS65 | Insects GDS65 | Heat days 34-36o GS60-79 | Frost days 0 to -2o GS60-79 | Frost days < -2o GS60-79 | ||||||||

3352 | 2015 | Lentils | 0.9 | 1 | 3 | 0 | |||||||||||||||||||

2016 | Wheat | 6.1 | 2.2 | 6.6 | 8 | 18 | 136 | 626 | Rhizoc high | Low | Rye1 | RWA1 | 0 | 0 | 0 | ||||||||||

2017 | Lentils | 0.9 | 0 | 0 | 0 | ||||||||||||||||||||

2018 | Wheat | 3.3 | 3.4 | 157 | 138 | nd | Low | Rye2 | |||||||||||||||||

3353 | 2015 | Lentils | 1.2 | 1 | 3 | 0 | |||||||||||||||||||

2016 | Wheat | 6.0 | 4.3 | 6.6 | 9 | 15 | 118 | 727 | Rhizoc high | Low | 12% | 0 | 0 | 0 | |||||||||||

2017 | Lentils | 1.0 | 0 | 0 | 0 | ||||||||||||||||||||

2018 | Wheat | 3.4 | 3.8 | 141 | 461 | nd | Low | Rye2 | |||||||||||||||||

3414 | 2015 | Wheat | 4.1 | 2.1 | 2.1 | -93 | 22 | 314 | 219 | Rhizoc high | Low | Rye68 | 3 | 0 | 0 | ||||||||||

2016 | Lentils | 6.0 | Rye2 | 0 | 0 | 0 | |||||||||||||||||||

2017 | Wheat | 5.5 | 3.5 | 3.5 | -57 | 26 | 305 | 179 | nd | Mod | Rye26 | 0 | no data | no data | |||||||||||

2018 | Lentils | 1.2 | Rye10 | ||||||||||||||||||||||

3415 | 2015 | Wheat | 3.0 | 1.9 | 1.9 | -57 | 17 | 294 | 301 | nd | Low | Rye1 | 3 | 0 | 0 | ||||||||||

2016 | Lentils | 4.9 | Medic6 | 0 | 0 | 0 | |||||||||||||||||||

2017 | Wheat | 3.3 | 1.8 | 1.8 | -83 | 19 | 272 | 203 | nd | Mod | 0 | no data | no data | ||||||||||||

2018 | Lentils | 1.3 | 0.1 | 0.1 | Rye1 | ||||||||||||||||||||

3416 | 2015 | Wheat | 4.6 | 2.0 | 2.0 | -132 | 27 | 251 | 199 | nd | Mod | 16% | Rye28 | 2 | 0 | 0 | |||||||||

2016 | Lentils | 2.6 | 37 | Rye34 | 0 | 0 | 0 | ||||||||||||||||||

2017 | Wheat | 5.5 | 1.2 | 1.2 | -363 | 38 | 129 | 138 | nd | nd | Rye108 | 0 | 0 | 0 | |||||||||||

2018 | Lentils | 0.8 | 51 | Rye21 | |||||||||||||||||||||

3417 | 2015 | Wheat | 3.8 | 3.0 | 3.0 | -29 | 20 | 289 | 247 | nd | Mod | Rye16 | 2 | 0 | 0 | ||||||||||

2016 | Lentils | 4.3 | 10 | 0 | 0 | 0 | |||||||||||||||||||

2017 | Wheat | 4.8 | 3.7 | 3.7 | -30 | 24 | 227 | 190 | nd | nd | Rye11 | LucF27 | 0 | 0 | 0 | ||||||||||

2018 | Lentils | 0.9 | |||||||||||||||||||||||

3418 | 2015 | Wheat | 1.5 | 5.4 | 5.8 | 74 | 6 | 161 | 341 | nd | Mod | Rye1 | 0 | 0 | 2 | ||||||||||

2016 | Wheat | 8.2 | 6.5 | 7.4 | -11 | 23 | 254 | 394 | nd | Mod | RWA5 | 0 | 0 | 0 | |||||||||||

2017 | Lentils | 1.5 | 0 | 0 | 0 | ||||||||||||||||||||

2018 | Wheat | 1.5 | 3.9 | 3.9 | 62 | 193 | 466 | Report 60 to 90% loss | |||||||||||||||||

3419 | 2015 | Wheat | 2.5 | 5.8 | 5.8 | 57 | 9 | 201 | 325 | nd | Mod | 20% | Rye6 | LucF96 | 0 | 0 | 2 | ||||||||

2016 | Wheat | 6.9 | 6.9 | 7.6 | 9 | 11 | 287 | 460 | nd | Mod | RWA6 | 0 | 0 | 0 | |||||||||||

2017 | Lentils | 1.5 | Rye1 | 0 | 0 | 0 | |||||||||||||||||||

2018 | Wheat | 2.2 | 5.0 | 5.0 | 56 | 234 | 353 | Rye5, Br2 | Report 50% loss | ||||||||||||||||

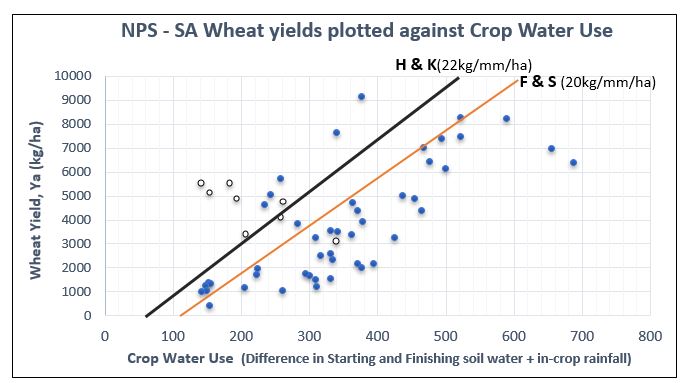

Assessing crop performance: WUE versus modelling

The first paper on WUE was published by French and Schultz in 1984. It was a break through at the time, enabling growers and agronomists to benchmark crop performance against a target and compare performance against other wheat crops. The French and Schultz WUE equation has since been updated by Sadras and Angus (2006) and Hunt and Kirkegaard (2012).

Hunt and Kirkegaard (2012) calculate Crop Water Use as: Soil water pre-sowing – Soil water post- harvest + Rainfall during the same period. WUE is then calculated as Yield (kg/ha) / (Crop Water Use - 60). Potential yield is calculated as 22 x (Crop Water Use – 60).

The SA 2015 to 2018 NPS wheat yields are plotted against Crop Water Use in Figure 4. The graph reveals a general tendency for Ya to increase with Crop Water Use with an upper boundary of yield. The upper boundary is reasonably interpreted as Yw for well-managed crops as Crop Water Use increases. The two lines included on the diagram are the Yw lines proposed by French and Schultz (1984) and Hunt and Kirkegaard (2012) calculated as Yw = 22 x (Crop Water Use – 60), to describe the most efficient use of water. This establishes a common maximum WUE of 22kg/mm/ha.

Figure 4. South Australian NPS wheat yields (Ya) plotted against Water Use (2015 to 2018) (note: the open circles are paddocks with chicken manure).

The other outliers are located on the Yorke Peninsula and on the Eyre Peninsula.

How useful is WUE compared with computer modelled assessments of potential yield and what will the future hold?

Figure 4 and other data analysed by French and Schultz (1984) and Sadras and Angus (2006) demonstrates a considerable variation in Ya relative to Yw, i.e. a considerable yield gap in many crops. Key questions for growers and agronomists are what is the cause of the yield gap in each individual case and how can it be alleviated?

There are many possible causes that cannot be identified without careful paddock monitoring of abiotic and biotic factors, as attempted in the present project.

We must remember that WUE to assess yield potential is a ‘bucket approach’ to a complex problem in a system with many interactions. WUE will not explain the causes of a yield gap, nor can it inform on reasons for favourable outcomes. It may identify the presence of a yield gap but not their cause.

Causes of yield gaps

Abiotic factors

Variability is a feature of farming in Australia and there are several reasons why crop roots cannot access soil water such as soil type (texture) and physical and chemical limitations. Chemical and physical constraints to root development can have a large impact on potential yield.

Interactions between soil type, available soil water and the amount of water extracted by the growing crop are influenced by crop growth and the distribution and amount of rainfall. If these factors are ignored there is limited predictive capability of yield.

High and low temperatures at critical times of crop development also can cause devastating yield loss.

Biotic factors

Crop nutrition appropriate to achieving potential yield (Yw) is relatively well understood and in the case of N, with many examples of successful tactical responses to fertilisation. But this is not matched for other nutrients such as phosphorus (P) and potassium (K), and micronutrients such as zinc (Zn).

Major infestations of weeds, pests and diseases can cause dramatic yield loss and less serious infestations may cause greater losses than is commonly appreciated and remain unknown without careful paddock monitoring.

The nature of these biotic causes of yield loss vary greatly from site to site, paddock to paddock and within paddock also.

Going forward with crop simulation models

Crop models, such as APSIM used in this study, are focussed on abiotic factors, but include biotic factors such as N nutrition. Their objective is to simulate yield (Ysim) in the absence of biotic factors such as weeds, diseases and pests and to estimate Yw by removing the effect of N shortage. For this, APSIM grows the crop on a daily time step and takes into account daily solar radiation, rainfall and availability of N. It uses soil-specific information for the crop lower limit (CLL) (wilting point) of the soil, defined as the soil water content below which water is not accessible to the crop. CLL is influenced by soil texture (sand, silt, clay content) and subsoil limitations (such as high chloride levels). APSIM also explains the importance of rainfall distribution in terms of growth reductions due to transient water stress. Extreme events of temperature (hot and cold), which may be important at less-than daily time scales need to be further addressed.

Over the last decade our industry has made huge advances in engineering, with precision agriculture enabling mapping soil types across paddocks, understanding what affects the crop’s ability to extract water and most importantly empowering growers to adopt precision seeding and to apply nutrients as required.

To fully utilise the power of crop models, on-the-go modelled outputs to field operations need to be incorporated, such as seeding and nutrient applications. This could well be the next frontier in crop management. Biotic stresses such as weeds, diseases and pests can be included if the appropriate in-field observations are made.

Conclusion

The NPS project has demonstrated that, as crop management becomes more sophisticated, it is essential to understand the reasons why crops fail to perform at their potential. When the reasons for why crops do not reach their potential yield is understood, consultants can better advise the growers that they are working with.

References

French, R.J. and Schultz, J.E. 1984. Water use efficiency of wheat in a Mediterranean-type environment: 1. The relationship between yield, water use and climate. Australian Journal of Agricultural Research 35, 743-764.

Hochman, Z., Gobbett, D., Horan, H., Navarro Garcia, J., 2016. Data rich yield gap analysis of wheat in Australia. Field Crops Res. 197, 97-106.

Hochman, Z. & Horan, H. 2018. Causes of wheat yield gaps and opportunities to advance the water-limited yield frontier in Australia. Field Crops Research 228, 20-30.

Holzworth, D.P., Huth, N.I., et al. 2014. APSIM – evolution towards a new generation of agricultural systems simulation. Environ. Model. Software. 62, 327–350.

Hunt, J. & Kirkegaard, J. 2012. A guide to consistent and meaningful benchmarking of yield and reporting of water-use efficiency. CSIRO publication (GRDC National Water-Use Efficiency Initiative).

Lawes. R., Chen. & van Rees. 2018. The National Paddock Survey – What causes the yield gap across Australian paddocks? GRDC Grains Research Update, Wagga Wagga, February 2018.

Sadras, V. & Angus, J. 2006. Benchmarking water-use efficiency of rainfed wheat in dry environments. Australian Journal of Agricultural Research 57, 847-856.

van Rees, H., McClelland, T., Hochman, Z., Carberry, P., Hunt, J., Huth, N. & Holzworth D. (2014). Leading farmers in South East Australia have closed the exploitable wheat yield gap: Prospects for further improvement. Field Crops Research 164, 1-11.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support. The support of GRDC staff in the regional offices is also much appreciated.

Contact details

Harm van Rees

RSD Mandurang South Victoria 3551

0419 325 252

harm@cropfacts.com.au

GRDC Project Code: BWD00025,

Was this page helpful?

YOUR FEEDBACK