Quality assessment of Australian oat varieties and their performance in processing Asian oat products.

Author: Dr Sabori Mitra, Mr Nabeen Dulal and Mr Mark Tucek (Australian Export Grains Innovation Centre (AEGIC), South Perth, WA 6151, Australia). | Date: 26 Feb 2019

Key messages

- There is the potential to increase the demand for Australian oats as a high value crop domestically and in the export market, especially in Asia through new oat-based foods.

- The quality of Australian oat varieties can be affected by genotype and growing season.

- Varietal variation of oats in their composition and physical properties making them particularly suitable for different oat-based food products according to different or specific end-user requirements.

- Australian oat varieties are suitable to produce traditional oat flakes and several innovative oat-based Asian style food products such as oat noodle and oat rice.

Introduction

Oat is known for its health benefits mainly due to its β-glucan content, along with other soluble/insoluble dietary fibre, nutritionally superior protein, fatty acids and micronutrients (Webster 2002; Rasane et al 2015). Market demand for Australian oats has been increasing due to the growth of health-conscious middle-class population in Asian countries, especially China. Australia’s reputation for growing high quality, clean and safe milling oats along with its geographical proximity make it an ideal source of oats to the expanding Asian markets. Due to an increase in consumers’ desire for healthier lifestyle, the Chinese health food market is becoming more sophisticated. This is increasing the utilisation of oats not only as breakfast items, such as flakes, but also as new oat-based Asian style food products such as oat rice, oat noodles and oat milk. In-market analyses conducted during this project showed that quality requirements of oats for processing these new products are beginning to become more sophisticated. As oat markets become more sophisticated, an understanding of the variation of qualities between different oat varieties and their suitability for different oat food products will create value by allowing selection of oat varieties for specific end products. This understanding may also positively influence breeding targets. The technical information from this work will also support the demand of Australian oats in China, and other Asian as well as domestic markets.

Aims

To increase the value and consumption of Australian export oats by:

- better understanding the variation in quality characteristics between Australian oat varieties; and

- investigating the functionality of Australian oat varieties and their suitability for various oat-based Asian food products.

Methods

Oat samples

A total of eight Australian milling oat varieties (Bannister, Dunnart, Mitika, Williams, Wombat, Yallara, Durack and Kowari) were selected from four different locations: Cunderdin and Pingelly in Western Australia (WA); and Riverton and Turretfield in South Australia (SA) over two growing seasons (2015 and 2016).

Oat sample preparation

Farmer dressed oats from WA and SA were cleaned and sorted to remove contaminants, free groats, immature and undersize oat grains. Oat kernels were de-hulled into groats (non-heat treated groats: NHT) which were cleaned to remove the residual hull and dust. Heat treatment of groats was achieved using a combi-steamer oven. A hydrothermal treatment was developed through multiple trials for efficient and complete deactivation of rancidity causing oat enzymes. Heat treated (HT) groats were milled into wholegrain flour using a rotor beater mill fitted with a sieve.

Oat product processing

Oat-wheat noodles: Oat-wheat noodles were processed using more than 50% oat flour mixed with wheat flour, salt, distilled water and additives acceptable in the Chinese industry. The oat-wheat noodle crumb made with wholegrain oat flour of different varieties was incubated before sheeting and cutting into noodle strands. Noodles were dried under controlled conditions. The noodle samples were then used for sensory and instrumental analyses.

Oat rice: The oat rice samples were pearled using a standardised method which did not compromise the β-glucan content and also improved its cooking quality i.e. reduced the cooking time similar to that of white rice. Presentation of the product is similar to rice and it could be a substitute for and blended with rice in many recipes.

Analyses of oat and oat products

Quality parameters of oat and oat-based food products were analysed to correlate them with functional properties and sensory panellist preferences. For oat kernel, hectolitre weight (HLW) and groat percentage were measured. The physical properties of oat groats such as colour, dimensions and shape of the groats were also measured. Hardness index and pasting properties of the wholegrain flour were also determined. The chemical composition of groats such as starch, fat, protein, and β-glucan were analysed along with mineral composition. Total dietary fibre, amylose, ash and fatty acid composition were also measured. Protein, starch, fat, fatty acid composition, total dietary fibre and β-glucan are reported on dry weight basis.

Texture analysis, colour and cooking loss of solids were measured as the quality parameters of oat-wheat noodles. Similarly, quality parameters of oat rice such as texture and colour were measured. Sensory analyses of the selected oat products were conducted in China by nine Chinese panellists who were trained for sensory analyses of each products separately.

All the oat quality and oat product quality parameters were measured using standard and/or published methods. The statistical analyses of variance (ANOVA) was performed and correlations between variables were identified.

Results

Oat quality

Variation in HLW of oat kernels was observed amongst the varieties. Durack had the significantly highest HLW (60.1kg·hl-1) while Dunnart (54.16kg·hl-1) had the lowest. Similar variation was also observed in groat percentage. Yallara had the highest groat percentage (72.7%) followed by Kowari (72.4%) and Durack (71.9%) while Williams had the lowest groat percentage (68.1%). However, it has be noted that the variation in the size of oat kernels affect their packing characteristics while measuring their HLW (Doehlert et al 2006). Therefore, groat percentage is a better indicator of milling yield for oat varieties than HLW. Although, Yallara and Durack had the highest groat percentage, their β-glucan content was relatively low. Kowari on the other hand stands out as it had relatively high β-glucan content and groat percentage: varieties with such quality characteristics are likely to be preferred by milling customers.

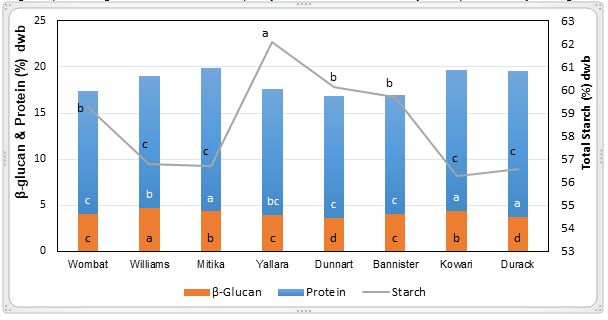

Figure 1. β-glucan, protein and starch content in oats.

Protein (12.92%-15.79%), β-glucan (3.64%-4.69%) and starch content (56.27%-62.08%) of groats for different Australian oat varieties are illustrated in Figure 1. Protein and β-glucan content were found to have a significant negative association with total starch content. Generally, a higher accumulation of protein and β-glucan in grain is known to reduce the energy available for starch accumulation during grain filling. Therefore, Yallara having the highest starch content, can be noted to have the lowest protein and β-glucan content combined (Figure 1). Williams, Mitika and Kowari on the other hand had highest β-glucan and protein content, and low total starch content.

Significant variation was observed amongst the Australian oat varieties for β-glucan, total dietary fibre, insoluble dietary fibre, amylose, ash, protein, lipid, total starch and all minerals except Selenium. Growing years or seasons had a significant impact on some important quality parameters of oats. In the 2015 growing year, β-glucan and amylose content were significantly higher while soluble and total dietary fibre content were significantly lower than in 2016. Year 2016 was a wetter and cooler growing season compared to 2015. This supports previous findings (Stewart and McDougall 2014) that a warmer and dryer climate is known to have a positive effect on β-glucan content.

The information of varietal variations on oat quality observed in this work is likely to grow in importance for the Chinese oat market over the next 5-10 years as this market becomes more technically sophisticated. Although, in more sophisticated Asian oat markets such as Taiwan β-glucan content of oats is an important quality parameter for selection of oat varieties, for the Chinese market, β-glucan content of oats is not universally a vital grain quality. However, as the middle-class Chinese population is becoming more health conscious, the nutritional qualities such as β-glucan will drive the consumption of oats in future. Research can support increased demand for Australian oats by developing new and innovative healthy oat food products.

From in-market survey it was noted that the Chinese markets are constantly looking for new marketing benefits to increase demand for oat-based food products. Some aspire to label their oat food products as a “superfood” for attracting more consumers. There are other nutritional aspect which could be researched to further enhance the health image of oats. Along with β-glucan, oats are also rich in other health promoting nutrients such as minerals and fatty acids. In comparison to other cereals, the concentration of minerals is relatively high in oats (Welch 2011). The mineral composition of oat varieties was determined as: potassium (2756-3156mg/kg), calcium (357-440mg/kg), iron (30.31-39.25mg/kg), zinc (16.38-21.88mg/kg), sodium (14.18-26.31mg/kg) and selenium (0.19-0.24mg/kg). Kowari had the highest amount for most of the minerals followed by Durack, Wombat and Mitika. The fat content (7.8%-11.2%) of oats comprised of a good balance of monounsaturated fatty acids (MUFA:50%), polyunsaturated fatty acids (PUFA: 40%). The majority of fatty acids such as oleic acid (MUFA) and linoleic acid - Omega - 6 (PUFA) contained in oats can promote heart health (Clifton and Keogh 2017). Yallara, Dunnart and Williams had highest linoleic acid.

Oat product quality

Oat-wheat noodles: We successfully incorporated more than 50% oat flour in oat-wheat noodles and produced acceptable quality dried oat-wheat noodles. The addition of oat flour in the wheat noodle formulation produced oat-wheat noodles with lower brightness and yellowness, and higher redness value as shown in Figure 2. However, health-conscious consumers associate white-coloured cereal products as being processed from ingredients depleted in nutrients and therefore consider dark-coloured noodles with specks more appealing (Mitra et al 2012; Izydorczyk et al 2005).

Figure 2. Image of cooked oat-wheat noodle and wheat noodle.

The project found that the Chinese market prefers oat noodles which reflect the colour of oats, however, they still prefer the oat noodles to be bright. Durack and Mitika produced the brightest noodles followed by Yallara while Williams produced the darkest noodles.

The composition of oat flour affects its pasting properties (peak viscosity: PV; final viscosity: FV) which can influence oat-wheat noodle quality. Oat flour pasting PV and FV were positively correlated with protein and β-glucan and negatively correlated with lipid. The high water binding capacity of β-glucan is known to increase the PV (Choi et al 2012). However, lipids tend to interact with starch granules and interfere in their complete hydration, which affects gelatinisation or pasting properties of oat flour (Zhou et al 1999; Mitra et al 2016). Therefore, the pasting properties of oat flour are not only dominated by starch and protein but also their interaction with other components such as β-glucan and lipids. The oat varieties such as Kowari and Mitika had the highest peak viscosity (PV) while Yallara and Kowari had the highest final viscosity (FV).

Similar to the pasting properties of oat flour, the composition of oats also influenced the textural properties of oat-based food products. For instance, the Australian oat-wheat noodles were found to be softer than wheat noodles due to the presence of β-glucan and other additives which aid in more water absorption. Similarly, recovery to compression (REC) which is a texture measurement that mimics chewing, and resiliency which defines how well the noodle fights to regain its original height after compression were positively correlated with protein. Resiliency was positively correlated with β-glucan and all textural parameters were negatively correlated with fat. Oat-wheat noodles made with Mitika, Yallara and Wombat had the highest resilience and REC. It was also found that oat flour pasting PV and FV were positively correlated to firmness and resilience of oat-wheat noodles. Varietal variation in the composition of oats was observed to influence the oat flour pasting properties and noodle textural parameters.

The Chinese sensory panel selected Wombat, Mitika, Yallara and Kowari as the most preferred oat varieties for oat-wheat noodles when different varieties of oat were evaluated from a location and a growing season. Cooking loss of solids in cooking water of oat-wheat noodles ranged from 8.7% to 9% and did not significantly vary between varieties, locations and year of cultivation. A positive correlation was found between starch damage and cooking loss.

Oat-rice quality

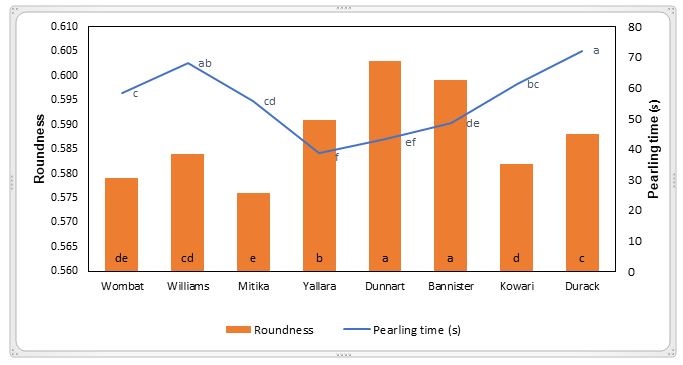

Oat rice processing was influenced by the physical characteristics of groats. The roundness of groats had a negative association and the hardness of groats had a positive association with pearling time. Figure 3 illustrates that Dunnart and Bannister have the highest roundness values and require the least time to pearl.

Pearling improved the colour and cooking time of oat rice in comparison to oat groats. Brightness was increased, redness was decreased, and yellowness remained unchanged for uncooked oat rice. For cooked oat rice colour, Mitika was the brightest followed by Durack, Yallara and Wombat. The redness value of oat rice was highest for Kowari. The yellowness value, which is the most preferred colour parameter in the Chinese market (as per verbal communication with Chinese oat rice processors), was high for Dunnart, Durack and Wombat. The impact of pearling on β-glucan for all Australian varieties processed into oat rice from one location and year indicated that there was no significant reduction in β-glucan content due to the pearling process.

Figure 3. Relationship between roundness and pearling time of NHT groats.

The textural properties of oat rice analysed instrumentally showed that all its parameters such as hardness, adhesiveness, springiness, cohesiveness, gumminess, chewiness and resilience had varietal variations. For instance, Kowari had the highest hardness which was followed by Yallara, Dunnart, Durack and Mitika.

Durack, Yallara, Dunnart and Wombat were selected as the most preferred oat varieties for processing oat rice when different Australian oat varieties from a location and a growing season were evaluated by the Chinese sensory panel. The panel selected these varieties based on aroma, taste, appearance and textural properties. Few of these selected varieties could be differentiated using the instrumental analysis. For example, Dunnart and Yallara had higher hardness values. Additionally, Yallara and Wombat had higher brightness values, and all selected varieties had higher yellowness values which is the preferred colour of oat rice in the Chinese market. Therefore, the statistical analyses will be performed to correlate the quality parameters of oats, different instrumental quality parameters of oat products and sensory results for all the oat-based food products processed in this work.

The oat rice processed by the standardised method has a great potential as a minimally processed food product in Asian and domestic markets due to its improved cooking time, appealing taste and texture properties and unaffected β-glucan content.

Conclusions

Varietal variation was significant for most of the oat quality parameters and such information will be of value in technically sophisticated markets. Seasonal variation was also noted for some of the oat quality parameters. A warmer and dryer growing year (2015) had a positive impact on β-glucan content in comparison to a wetter and cooler growing season (2016). A higher accumulation of protein and β-glucan had a negative association with starch accumulation during grain filling.

Although β-glucan content of oat is not a universally important quality parameter at present amongst Chinese oat processors, the increase in health-conscious population in China will drive the consumption of oat products for nutritional benefits offered by β-glucan over time. Along with the benefits of β-glucan, the balanced composition of MUFA and PUFA together with a higher content of minerals such as potassium, calcium, iron, sodium and selenium in the oats will increase its demand in the health markets.

The oat flour composition was successfully increased to more than 50% of the oat-wheat blend in the development of high quality, dried oat-wheat noodles. From instrumental analyses, Durack and Mitika were found to produce the brightest oat-wheat noodles followed by Yallara. Chewiness and resiliency were the highest for Mitika, Yallara and Wombat. For oat-wheat noodles, the sensory panel chose Wombat, Mitika, Yallara and Kowari as the most preferred oat varieties.

Pearling to produce oat rice improved colour and texture properties and reduced the cooking time of groats without deteriorating its β-glucan content. Oat rice has considerable market potential as a minimally processed staple food product with very high nutrient value. The sensory panel selected Durack, Yallara, Dunnart and Wombat as the most preferred varieties for oat rice. Instrumental textural parameters such as hardness of oat rice was higher from Durack, Dunnart, Yallara, Mitika and Kowari. Furthermore, instrumental quality analyses of oat rice showed that Durack and Wombat had the highest brightness and yellowness values as preferred by the Chinese market.

In the final reporting of this project, the quality analyses of six Chinese oat varieties (Baiyan 11, Yanke 2, Dingyou 9, Bayou 1, Baiyan 2 and Bayou 6) grown over two years (2016 and 2017) in two locations (Hebei-Zhangjiakou, Inner Mongolia-city of Wulanchabu) along with their performance when processed into four oat products (oat noodles, oat rice, oat milk and oat flakes) will be included. This dataset will be used to benchmark the quality and performance of the oat varieties from both China and Australia in oat-based Asian style food products. Complete sensory data on the oat products processed using Australian and Chinese varieties will also be included in the final report.

Knowledge of the variation of qualities between different oat varieties and their suitability for different oat products will drive increased value for growers as oat markets continue to become more sophisticated over time. High quality oat noodles and oat rice products using Australian oats varieties were produced. With these examples of innovative oat food products, oats have the potential to increasingly become a staple of daily diets, moving beyond just breakfast style foods. This could offer big potential for increased demand for oats in future.

References

Choi, I., Han, O., Chun, J., Kang, C. S., Kim, K. H., Kim, Y. K., Cheong, Y., Park, T., Choi, J. S. and Kim, K. J. 2012. Hydration and pasting properties of oat (Avena sativa) flour. Prev. Nutr. Food Sci. 17:87.

Clifton, P. and Keogh, J. 2017. Dietary fats and cardiovascular disease: an evidence check rapid review brokered by the Sax Institute for the National Heart Foundation of Australia.

Doehlert, D.C., McMullen, M.S., and Jannik, J.L. 2006. Oat grain/groat size ratios: A physical basis for test weight. Cereal Chem. 83(1): 114-118.

Izydorczyk, M. S., Lagassé, S. L., Hatcher, D. W., Dexter, J. E. and Rossnagel, B. G. 2005. The enrichment of Asian noodles with fibre-rich fractions derived from roller milling of hull-less barley. J. Sci. Food Agric. 85:2094-2104.

Mitra, S., James, A.P., Fenton, H.K., Cato, L., Solah, V.A. 2016. The impact of oat quality on white salted noodles containing oat flour. Cereal Chem. 93(3): 282-292.

Mitra, S., Cato, L., James, A. P. and Solah, V. A. 2012. Evaluation of white salted noodles enriched with oat flour. Cereal Chem. 89:117-125.

Rasane, P., Jha, A., Sabikhi, L., Kumar, A. and Unnikrishnan, V. S. 2015. Nutritional advantages of oats and opportunities for its processing as value added foods - a review. J. Food Sci. Technol. 52:662-675.

Stewart, D. and McDougall, G. 2014. Oat agriculture, cultivation and breeding targets: implications for human nutrition and health. Bri. J. Nutr. 112: S50-S57.

Webster, F. H. 2002. Whole-grain oats and oat products. Pages 83-123 in: Whole-Grain Foods in Health and Disease. L. Marquart, J. L. Slavin and R. G. Fulcher, eds. AACC: St. Paul, MN, USA.

Welch, R. 2011. Nutritional composition and nutritional quality of oats and comparisons with other cereals. Pages 95-105 in: Oats: chemistry and technology. F. Webster and P. Wood, eds. American Association of Cereal Chemists: St. Paul: MN.

Zhou, M., Robards, K., Glennie-Holmes, M. and Helliwell, S. 1999. Effect of oat lipids on groat meal pasting properties. J Sci. Food Agric. 79: 585-592.

Acknowledgements

We would like to acknowledge the contribution of our collaborators for this report, Dr Pamela Zwer and Peter McCormack from SARDI (National Oat Breeding Program) for providing us with all the Australian oat samples; Prof. Xinzhong Hu and his team from Shaanxi Normal University, China for providing Chinese samples, technical support and significantly contributing to data collection for this project; Dr Glen Fox (Senior Research Fellow) and Thoa Nguyen (PhD Student) from Queensland Alliance for Agriculture and Food Innovation (QAAFI), University of Queensland for analysing and providing the carbohydrate data. We would also like to appreciate Ms Regina Buswell from AEGIC for her contribution to this work. The research undertaken as part of this project was made possible by the co-investment of GRDC and AEGIC. The authors would also like to thank GRDC for their continued support.

GRDC Project Code: AEG00007,

Was this page helpful?

YOUR FEEDBACK