Summary of key weed research activities in the northern grains region

Author: Michael Walsh (University of Sydney) | Date: 26 Feb 2019

Take home messages

- High amounts of chaff are required for suppression of weed emergence in chaff lines.

- ‘Weed chipper’ is a targeted tillage system for fallow weed control.

- Site-specific weed control creates the opportunity to use alternative physical weed control technologies.

Background

Chaff lining and chaff tramlining

With many annual weeds in Australian cropping systems retaining their seed at maturity, harvest weed seed control (HWSC) is an alternative approach to weed control that is now widely adopted by Australian grain growers (Walsh et al. 2017). Several similarly effective HWSC systems have been developed to suit a range of crop production practices (Walsh et al. 2013). Chaff lining and chaff tramlining have recently become very popular with growers due to the low cost and simplistic approach of these systems to targeting weed seeds at harvest. These techniques concentrate the chaff fraction into very narrow windrows (<30cm) directly behind the harvester or onto dedicated wheel tracks. The chaff environment is sub-optimal for seedling establishment and these practices can be as effective as other forms of HWSC (Broster et al. 2018).

Targeted tillage

Tillage can provide highly effective weed control, but when used conventionally (i.e. 100% soil disturbance), it cannot be routinely used in conservation cropping systems due to the impact on soil health. The development of weed detection technologies creates the opportunity to incorporate strategic tillage operations for targeting individual weeds or weed patches in fallow situations. The ’weed chipper’ is a targeted tillage system that incorporates weed detection with rapid response tynes for site-specific fallow weed control.

Alternative weed control technologies

Physical and thermal weed control techniques were in use well before herbicides were introduced and the development of new options has continued throughout the herbicide era. Most of these technologies have not been developed, primarily due to cost, speed of operation and fit within farming systems. The introduction of weed detection and actuation technologies creates the opportunity to target individual weeds. This greatly increases the cost-effectiveness of many directional alternative weed control techniques. The challenge now is to identify which of these research and development activities should focus on.

Materials and methods

Chaff lining and chaff tramlining

A series of pot experiments investigated the influence of increasing amounts of wheat, barley, canola and lupin chaff on the emergence of annual ryegrass. In trials at three locations — Toowoomba, Wagga Wagga and Narrabri, eight rates of chaff were spread over a known number of annual ryegrass seed (100 or 200) on the surface of potting mix filled trays or pots. Chaff amounts used (0, 3, 6, 12, 18, 24, 30, and 42t/ha) were calculated as amounts equivalent to those concentrated in a 30cm wide row during the harvest of 0, 0.25, 0.5, 1, 1.5, 2, 2.5 and 3.5t/ha yielding wheat crops using a 12m front. Once the chaff was evenly spread across the soil surface, the pots were watered thoroughly and maintained at or near field capacity for 28 days.

Chaff amount = 0.3 x grain yield (t/ha) x (harvester width (m)/tramline width (m)).

Note: Assuming chaff yield is 30% of grain yield.

Differences between chaff types and rates on annual ryegrass emergence over a 28 day period.

Targeted tillage

A rapid response tyne system has been developed with the operational specifications of being able to specifically cultivate targeted weeds when present in a field at densities of up to 1.0 plant/10m2 at an operational speed of 10km/h. The rapid response tyne was based on the retrofit of a Shearer Trashworker tyne with a hydraulic breakout system. The hydraulic breakout system is typical of many other manufacturers thus permitting a design approach which could be adapted to accommodate other arrangements. The design focused the engineering on minimising the number of additional components and keeping the design simple whilst achieving the chipping action similar to a conventional hoe in well under half a second. A modular approach to the design was taken so as to permit the system to be readily scaled.

Field testing using two prototype rigs at Narrabri and Toowoomba was conducted on a range of problematic fallow weed species. The targeted tillage system was evaluated in a series of field trials for efficacy on weeds of winter fallows (annual ryegrass, wild oats, sowthistle and wild turnip) and summer fallows (barnyard grass, feathertop Rhodes grass, fleabane and sowthistle). The efficacy of the response tyne on the targeted weeds species across a range of growth stages was also investigated.

Comparison of weed control technologies

There is a diverse array of alternative physical and thermal weed control technologies with a proven ability to control weeds. The majority of these have not been commercialised and evidence of their efficacy is from a range of strictly controlled laboratory trials or studies, making cost-effectiveness comparisons difficult. While inputs and control methods differ significantly between physical control options, all systems share an energy requirement value for activation and use. Therefore, the energy required for effective weed control can be a reasonably accurate approach to comparing the efficiency and efficacy of physical control systems on an energy consumed per weed or hectare basis.

The direct energy requirements for the control of two-leaf weed seedlings were estimated from published reports on the weed control efficacy of a comprehensive range of physical weed control techniques (Table 1). To determine the energy requirement per unit area, a weed density of 5.0 plants/m2 was chosen to represent a typical weed density in Australian grain fields (Llewellyn et al. 2016).

Results and discussion

Chaff lining and chaff tramlining

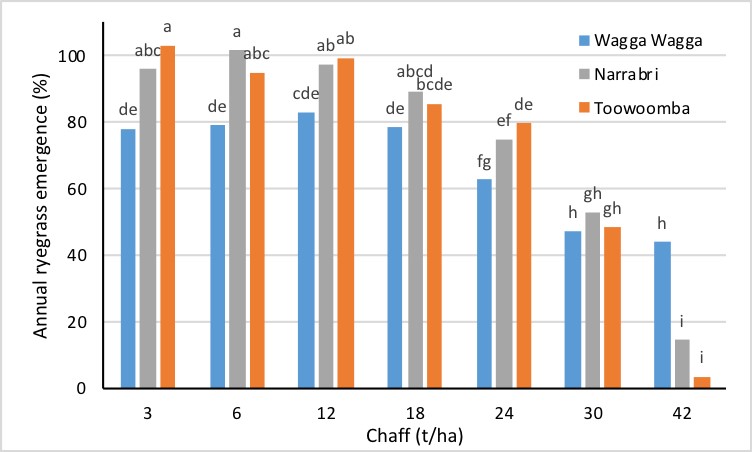

Preventing the emergence of annual ryegrass in chaff lining or chaff tramlining systems requires the concentration of very high rates (>42t/ha) of chaff material. The enhanced suppression of annual ryegrass emergence with increasing amounts of wheat chaff was clearly evident in pot trials conducted at three locations in 2018 (Figure 1). Regardless of location, there were no differences (P>0.05) in annual ryegrass emergence for chaff treatments between 3t/ha and 18t/ha (Figure 1). The 30t/ha and 42t/ha chaff treatments produced the lowest (P<0.05) emergence of just 49.5% and 20.7%, respectively. However, annual ryegrass emergence was not prevented in these studies, even at the highest wheat chaff rate of 42t/ha. At the lower chaff rates (3t/ha to 12t/ha), annual ryegrass emergence was consistently lower (P<0.05) at Wagga Wagga than the two other locations. Emergence in the Wagga Wagga trial was lower (P<0.05) than both sites at 3t/ha, 6t/ha and 12t/ha chaff rates and lower than one site at the 24t/ha chaff rate. However, at the 42t/ha chaff rate, emergence at Wagga Wagga was higher (P<0.05) than at the other two sites.

Figure 1. Influence of increasing amounts of wheat chaff on the emergence of annual ryegrass in pot trials conducted at three locations. Means with same letter are not significantly different (P=0.05.)

Barley chaff was generally more suppressive of annual ryegrass emergence at equivalent rates of wheat, canola and lupin chaff. When these four chaff types were compared in a single study at Wagga Wagga, there was generally lower annual ryegrass emergence through barley chaff, however these values were only significantly lower (P<0.05) at the highest chaff rates (30t/ha and 42t/ha) (Figure2).

Figure 2. Influence of increasing amounts of wheat, barley, lupin and canola chaff on the emergence of annual ryegrass in pot trials conducted at Wagga Wagga, NSW. Means with same letter are not significantly different (P=0.05).

Targeted tillage

Engineering research, development and testing were conducted on the University of Western Australia (UWA) test rig at (Figure 3A). As with any engineering design, the process involved iterative improvements to the design layout. Once the system was able to achieve a chipping cycle time of less than 400m from actuation to return to standby position and the design had been simplified and deemed reliable, the pre-commercial rig (Figure 3D) was designed and built.

Figure 3. Initial proof-of-concept rig, UWA (A), University of Sydney (USyd) trailer mounted self-powered rig (B), Qld Department of Agriculture and Food (QDAF) 3-point-linkage rig (C) and pre-commercial rig – the ‘Weed Chipper’ (D) used in the testing and validation of targeted tillage fallow weed control.

Weed kill field testing achieved very high efficacy on all targeted summer and winter annual weeds regardless of growth stage (Tables 1, 2 and 3). The survival of any weeds during testing was due to the design of current cultivator sweeps not being suitable for targeted tillage. Weed control was 100% effective when the weed was targeted by the point of the sweep, however there was high weed survival when the weed was hit by sweep side. There was also reduced efficacy when weeds were excessively large. When feathertop Rhodes grass was >70cm diameter, there was only poor control (Table 2). The system is highly effective on both broadleaf and grass weeds with potentially little resulting soil disturbance (Figure 4).

Table 1. Response tyne efficacy following direct or partial sweep impact on four winter and three summer weed species at eight growth stages, Narrabri, NSW, 2017 and 2018.

Planting date | Wild oats (% control) | Turnip weed (% control) | Sowthistle (% control) | Annual ryegrass (% control) | Feathertop Rhodes grass | Barnyard grass | Fleabane | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Direct contact | Partial contact | Direct contact | Partial contact | Direct contact | Partial contact | Direct contact | Partial contact | Direct contact | Partial contact | Direct contact | Partial contact | Direct contact | Partial contact | |

2 leaf | 100 | 0 | 100 | 100 | 100 | 100 | 0 | 100 | - | 100 | - | 100 | - | |

4 leaf | 100 | - | 100 | 0 | 100 | - | 100 | 0 | 100 | - | 100 | - | 100 | - |

6 leaf | 100 | - | 100 | 100 | 100 | - | 100 | 0 | 100 | - | 100 | - | 100 | - |

8 leaf | 100 | 0 | 100 | - | 100 | 100 | 0 | 100 | - | 100 | - | 100 | - | |

10 leaf | 100 | 0 | 100 | - | 100 | - | 100 | 0 | 100 | - | 100 | - | 100 | - |

Bolting/tillering | 100 | 0 | 100 | - | 100 | - | 100 | 0 | 100 | - | 100 | - | 100 | - |

Early flowering/heading | 100 | 0 | 100 | - | 100 | 100 | 0 | 100 | - | 100 | - | 100 | - | |

Flowering | 100 | - | 100 | - | 100 | - | 100 | 0 | 100 | - | 100 | - | 100 | 0 |

- Indicates no treatments where there was partial contact of the tyne with the weed.

Table 2. Response tyne efficacy on two winter weed species at three growth stages, Gatton, Qld, 2017.

| Weed Size | Wild Oats | Sowthistle |

Control (%) | ||

Small | - | 100 |

Medium | 100 | 85 |

Large | 98 | 75 |

* Indicates that established weeds were either missed by the tyne (alignment issue) or the tyne did not activate.

Table 3. Response tyne efficacy on three summer weed species at three growth stages, Gatton and Hermitage, Qld, 2017.

Summer 2016/2017 | Weed size | Barnyard Grass | Feathertop Rhodes Grass | Windmill Grass |

|---|---|---|---|---|

Control (%) | ||||

Gatton | Medium | 100 | 94 | 100 |

Large | 96 | 91 | 100 | |

X-Large | 99 | 87 | 96 | |

Hermitage | Medium | 98 | 78 | 100 |

Large | 92 | 33 | 100 | |

X-Large | 83 | 8 | * | |

* Indicates that established weeds were either missed by the tyne (alignment issue) or the tyne did not activate.

Figure 4. Wild oats pre- targeted tillage (A), post-targeted tillage (B) and the resulting ’divot’(C).

The efficacy of targeted tillage for weed control is entirely reliant on accurate weed detection. Given that the initial use of targeted tillage will be in fallow, then it is appropriate that current available real-time detection technologies be incorporated in preparation for commercial use. Current boom spray mounted detection systems (Weed Seeker® and WeedIt) are coupled to spray nozzles that can be rapidly triggered. Preliminary tests using the WeedIt sensing system on the Shenton Park rig demonstrated its high suitability for fallow weed control. The WeedIt system was chosen as being a more suitable system for targeted tillage and has now been incorporated into the pre-commercial Weed Chipper rig. Trials using the system coupled to a 6m pre-commercial Weed Chipper (Figure 3D) are currently underway.

Comparison of weed control technologies

As a group, soil disturbance-based options are the most energy efficient form of physical weed control when applied as a broadcast (whole field) treatment (Table 4) with no additional energy inputs beside the draft force requirements. Although tillage can be a highly effective weed control option, the soil disturbance involved is not compatible with conservation cropping systems and therefore, this approach needs to be used sparingly. There are a group of thermal weed control technologies (flaming, hot water foaming and steaming) using chemical or electrical energy that may be used for broadcast weed control (Table 4). In comparison to tillage and herbicide-based options, these approaches are considerably more energy expensive. With 100-fold to 1000-fold higher energy requirements, it is not surprising that these technologies have not been widely adopted for use in large scale cropping systems.

Table 4. Total energy requirement estimates for alternative weed control options applied as broadcast treatments. Estimates are based on the control of two-leaf weeds present at five plants/m2.

Weed control method | Energy consumption |

|---|---|

Flex tine harrow | 4 |

Sweep cultivator | 11 |

Rotary hoe | 13 |

Organic mulching | 16 |

Rod weeding | 18 |

Spring tooth harrow | 22 |

Basket weeder | 29 |

Roller harrow | 29 |

Disc mower | 31 |

Tandem disk harrow | 36 |

Flail mower | 57 |

Offset disk harrow | 64 |

| UV | 1701 |

Flaming | 3002 |

Infrared | 3002 |

Hot water | 5519 |

Hot foam | 8339 |

Steam | 8734 |

Freezing | 9020 |

| Hot air | 16902 |

| Microwaves | 42001 |

| Plastic mulching | 211003 |

Site-specific weed control

The opportunity for substantial cost savings and the introduction of novel tactics are driving the future of weed control towards site-specific weed management. This approach is made possible by the accurate identification of weeds in cropping systems using machine vision typically incorporating artificial intelligence. Once identified, these weeds can be controlled through the strategic application of weed control treatments. This precision approach to weed control creates the potential for substantial cost savings (up to 90%) and the reduction in environmental and off-target impacts (Keller et al. 2014). More importantly for weed control sustainability, site-specific weed management creates the opportunity to use alternative physical weed control options that currently are not suited for whole paddock use.

Accurate weed detection allows physical weed control treatments to be applied specifically to the targeted weed. As weed identification processes develop to include weed species, size and growth stage, there exists the potential for some approaches (such as electrical weeding, microwaving and lasers) to be applied at a prescribed lethal dose. This dramatically reduces the amount of energy required for effective weed control (Table 5). For example, microwaving, as one of the most energy expensive weed control treatment as a broadcast treatment (42,001 MJ/ha), requires substantially less energy when applied directly to the weed targets (17.8MJ/ha). Thus, even though the same numbers of weeds are being controlled (5 plants/m2) the specific targeting of these weeds results in a 99% reduction in energy requirements.

Table 5. Total energy requirement estimates for alternative weed control options when applied as site-specific treatment. Estimates are based on the control of two-leaf weeds present at five plants/m2.

Weed control method | Energy consumption |

|---|---|

Concentrated solar radiation | 14.4 |

Precise cutting | 14.4 |

Pulling | 14.4 |

Electrocution: spark discharge | 14.5 |

Nd:YAG IR laser pyrolysis | 15.2 |

Herbicides | 14.8 |

Hoeing | 15.7 |

Water jet cutting | 15.8 |

Stamping | 16.5 |

Nd:YAG IR laser pyrolysis | 16.9 |

Microwaves | 17.8 |

Abrasive grit | 24.5 |

Thulium laser pyrolysis | 25.9 |

CO2 laser cutting | 54.8 |

Targeted flaming | 59.9 |

Electrocution: continuous contact | 60.9 |

Nd:YAG laser pyrolysis | 84.4 |

CO2 laser pyrolysis | 92.3 |

Nd:YAG UV laser cutting | 129.4 |

Hot foam | 131.3 |

Dioide laser pyrolysis | 133.1 |

Nd:YAG IR laser cutting | 204.4 |

| Targeted hot water | 204.4 |

Conclusions

The emergence of annual ryegrass can be significantly suppressed by increasing amounts of chaff concentrated in chaff lines and chaff tramlines. It was only at very high rates of wheat (42t/ha) that the annual ryegrass emergence was effectively reduced, therefore much higher amounts will be needed to prevent suppression.

The Weed Chipper is currently being demonstrated throughout the northern grains region. It is hoped that this system will become widely used as an alternative to herbicides for fallow weed control.

The specific targeting of individual weeds results in significant energy savings and makes previously impractical options available for use in commercial production systems. The opportunities here are immense for the future management of problem weeds.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC — the author would like to thank them for their continued support.

References

Broster J, Rayner A, Ruttledge A, Walsh MJ (2018). Impact of stripper fronts and chaff lining on harvest weed seed control. GRDC Crop Updates. West Wyalong.

Keller M, Gutjahr C, Möhring J, Weis M, Sökefeld M, Gerhards R (2014). Estimating economic thresholds for site-specific weed control using manual weed counts and sensor technology: An example based on three winter wheat trials. Pest Management Science 70:200-211.

Walsh MJ, Newman P, Powles SB (2013). Targeting weed seeds in-crop: A new weed control paradigm for global agriculture. Weed Technology 27:431-436.

Walsh MJ, Ouzman J, Newman P, Powles SB, Llewellyn R (2017). High levels of adoption indicate that harvest weed seed control is now an established weed control practice in Australian cropping. Weed Technology. 31:1-7.

Contact details

Michael Walsh

University of Sydney

12656 Newell Highway, Narrabri 2390

02 6799 2201; 0448 847272

m.j.walsh@sydney.edu.au

Was this page helpful?

YOUR FEEDBACK