Weed control in Australian grain production systems, now and into the future

Author: Michael Walsh (University of Sydney), John Broster (Charles Sturt University) and Greg Condon (Grassroots Agronomy; 4Australian Herbicide Resistance Initiative) | Date: 19 Feb 2019

Take home messages

- Harvest weed seed control (HWSC) is an important component of a successful weed management package.

- Suppression of weed emergence increases with increasing amounts of chaff.

- Site-specific weed control creates the opportunity to use alternative physical weed control technologies.

Background

The reliance on herbicidal weed control has resulted in the widespread evolution of herbicide resistant weed populations (Boutsalis et al. 2012; Broster et al. 2013; Owen et al. 2014). Changing regulations and expensive herbicidal development costs, combined with the perennial threat of herbicide resistance, means the effectiveness of future weed control programs will depend on the availability of alternative weed control technologies.

With many annual weeds in Australian cropping systems retaining their seed at maturity, harvest weed seed control (HWSC) is an alternative approach to weed control that is now widely adopted by Australian grain growers (Walsh et al. 2017). Several similar effective HWSC systems have been developed to suit a range of crop production practices (Walsh et al. 2013). Chaff lining and chaff tramlining have recently become very popular with growers due to the low cost and simplistic approach of these systems to targeting weed seeds at harvest. These approaches to HWSC concentrate the weed seed bearing chaff fraction into very narrow windrows (<30cm) directly behind the harvester or onto dedicated wheel tracks. The chaff environment is sub-optimal for seedling establishment and this practice can be as effective as other forms of HWSC in depleting weed seed banks.

Physical and thermal weed control techniques were in use well before herbicides were introduced and the development of new options has continued throughout the herbicide era. However, most of these technologies have not been adopted, primarily due to cost, speed of operation and fit with new farming systems. The introduction of weed detection and actuation technologies creates the opportunity to target individual weeds i.e. site-specific weed management. This greatly increases the potential cost-effectiveness of many directional physical weed control techniques in conservation cropping systems.

The use of alternative weed control tactics is obviously critical to achieving near zero weed status, but ultimately successful growers keep seed bank numbers low every year through the strategic use of all available tools. This stems from a commitment by the grower and their agronomist to plan ahead and target weeds at every opportunity using an integrated approach, not just with herbicides alone. There are numerous benefits of near zero weed densities including reduced weed control costs, prevention/delayed herbicide resistance evolution and increased flexibility in production practices. Significantly, lower weed densities create the opportunity for using cheaper and more accurate site-specific approaches to weed control.

Materials and methods

Chaff lining and chaff tramlining

The purpose of the experiments was to investigate the influence of different amounts of wheat, barley, canola and lupin chaff on seedling emergence of annual ryegrass. Wheat chaff trials were conducted at three locations — Toowoomba, Wagga Wagga and Narrabri with barley, canola and lupin chaff trials at Wagga Wagga. The similar approach used at each location involved eight rates of chaff with four replicates of each experimental unit. The trials were established by spreading a known number of annual ryegrass seed (100 or 200) on the soil surface potting mix filled trays or pots. Treatments were established by spreading chaff material, collected during the 2017 harvest, over the surface of the pots or trays. Chaff amounts used (0, 3, 6, 12, 18, 24, 30, and 42t/ha) were calculated as amounts equivalent to those concentrated in a 30cm wide row during the harvest of 0, 0.25, 0.5, 1, 1.5, 2, 2.5 and 3.5t/ha yielding wheat crops using a 12m front. Once the chaff was evenly spread across the soil surface, the pots were watered thoroughly and maintained at or near field capacity for 28 days.

Chaff amount = 0.3 x grain yield (t/ha) x (harvester width (m)/tramline width (m))

Note: Assuming chaff yield is 30% of grain yield

Differences between chaff types and rates were assessed using emergence over the 28 day period as a proportion of the 0t/ha chaff treatment.

Comparison of weed control technologies

There is a diverse array of effective physical weed control options with a proven ability to control weeds. The majority of these have not been commercialised and evidence of their efficacy relates to research findings, making cost-effectiveness comparisons difficult. While inputs and control methods differ significantly between physical control options, all systems share an energy requirement value for activation and use. Therefore, the energy required for effective weed control can be a reasonably accurate approach to comparing the efficiency and efficacy of physical control systems on an energy consumed per weed or hectare basis.

The direct energy requirements for the control of two-leaf weed seedlings were estimated from published reports on the weed control efficacy of a comprehensive range of physical weed control techniques (Table 1). To determine the energy requirement per unit area, a weed density of 5.0 plants/m2 was chosen to represent a typical weed density in Australian grain fields, based on results from a recent survey of Australian grain growers (Llewellyn et al. 2016).

Results and discussion

Chaff lining and chaff tramlining

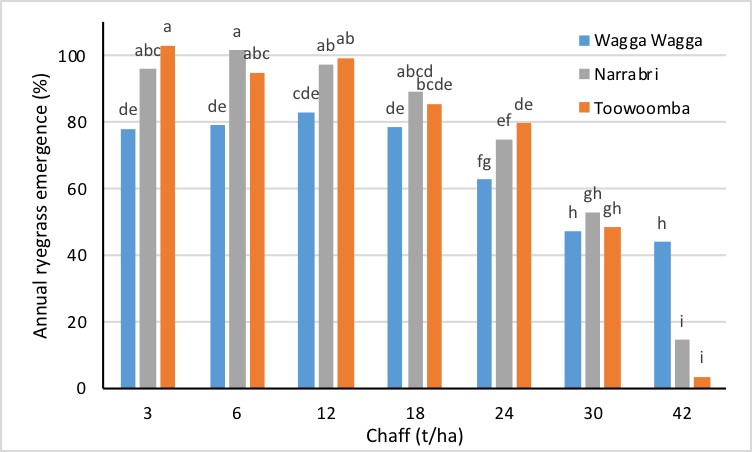

Preventing the emergence of annual ryegrass in chaff lining or chaff tramlining systems requires concentration of very high rates (>42t/ha) of chaff material. The increased suppression of annual ryegrass emergence with increasing amounts of wheat chaff was clearly evident in pot trials conducted at three locations in 2018 (Figure 1). Regardless of location, there were no differences (P>0.05) in annual ryegrass emergence for chaff treatments between 3t/ha and 18t/ha (Figure 1). The 30t/ha and 42t/ha chaff treatments produced the lowest (P<0.05) emergence of just 49.5% and 20.7%, respectively. However, annual ryegrass emergence was not prevented in these studies, even at the highest wheat chaff rate of 42t/ha. At the lower chaff rates (3t/ha to 12t/ha), annual ryegrass emergence was consistently lower (P<0.05) at Wagga Wagga than at the two other locations. Emergence in the Wagga Wagga trial was lower (P<0.05) than at both sites at 3t/ha, 6t/ha and 12t/ha chaff rates and lower than one of these sites at 24t/ha chaff rate. However, at the 42t/ha chaff rate, emergence at Wagga Wagga was higher (P<0.05) than at the other two sites.

Figure 1. Influence of increasing amounts of wheat chaff on the emergence of annual ryegrass in pot trials conducted at three locations. Means with same letter are not significantly different (P=0.05.).

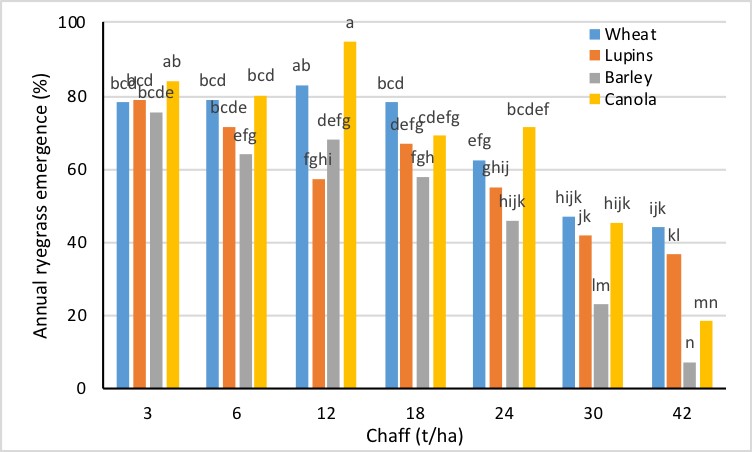

Barley chaff was generally more suppressive of annual ryegrass emergence at equivalent rates of wheat, canola and lupins. When these four chaff types were compared in a single study at Wagga Wagga, there was generally lower annual ryegrass emergence through barley chaff, however these values were only significantly lower (P<0.05) at the highest chaff rates (30t/ha and 42t/ha) (Figure 2).

Figure 2. Influence of increasing amounts of wheat, barley, lupins and canola chaff on the emergence of annual ryegrass in pot trials conducted at Wagga Wagga, NSW. Means with same letter are not significantly different (P=0.05).

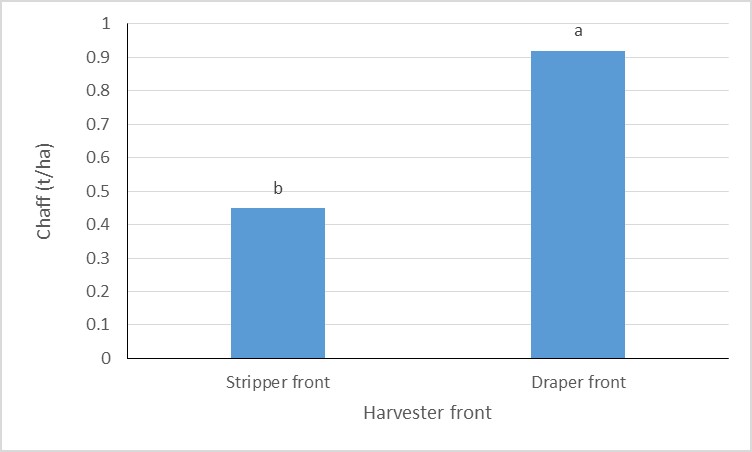

The greater emergence inhibition by the barley chaff at Wagga Wagga may be due to it being a greater physical barrier. For any weight of chaff, more barley chaff was needed than wheat chaff, with lupins and canola requiring even less. It is also unlikely that all crop species and/or varieties will have the same chaff percentage. In addition, a harvester using a stripper front will also produce less chaff (Figure 3) for a chaff line compared to a draper front.

Figure 3. Amount of chaff fraction (t/ha) produced when harvesting wheat using two different harvester fronts. Means with same letter are not significantly different (P=0.05).

Comparison of energy requirements for weed control

Historically, tillage was relied on for weed control as well as seedbed preparation and continues to be used extensively in global cropping systems despite the extensive reliance on herbicides. As a group, soil disturbance-based options are the most energy efficient form of physical weed control (Table 1) with no additional energy inputs beside the draught force requirements. Tillage acts to control weeds by uprooting plants, severing roots and shoots and/or burial of plants. Consequently, the efficacy and impact of this approach are reliant on rainfall and soil moisture. Effective control can only be achieved when disturbed weeds are exposed to a drying environment after the tillage operation. Although tillage can be a highly effective weed control option, the soil disturbance involved is not compatible with conservation cropping systems, therefore this approach needs to be used sparingly.

There are a group of thermal weed control technologies (flaming, hot water foaming, steaming, etc.) using chemical or electrical energy that may be used for broadcast weed control (Table 1). In comparison to tillage and herbicide-based options, these approaches are considerably more energy expensive. With 100 to 1000-fold higher energy requirements, it is not surprising that these technologies have not been widely adopted for use in large scale cropping systems, although in more intensive operations, flaming is used to some extent.

Table 1. Total energy requirement estimates for alternative weed control options applied as broadcast treatments. Estimates are based on the control of two-leaf weeds present at five plants/m2.

Weed control method | Energy consumption |

|---|---|

Flex tine harrow | 4 |

Sweep cultivator | 11 |

Rotary hoe | 13 |

Organic mulching | 16 |

Rod weeding | 18 |

Spring tooth harrow | 22 |

Basket weeder | 29 |

Roller harrow | 29 |

Disc mower | 31 |

Tandem disk harrow | 36 |

Flail mower | 57 |

Offset disk harrow | 64 |

UV | 1701 |

Flaming | 3002 |

Infrared | 3002 |

Hot water | 5519 |

Hot foam | 8339 |

Steam | 8734 |

Freezing | 9020 |

Hot air | 16902 |

Microwaves | 42001 |

Plastic mulching | 211003 |

Site-specific weed control

The opportunity for substantial cost savings and the introduction of novel tactics are driving the future of weed control towards site-specific weed management. This approach is made possible by the accurate identification of weeds in cropping systems using machine vision typically incorporating artificial intelligence. Once identified, these weeds can be controlled through the strategic application of weed control treatments. This precision approach to weed control creates the potential for substantial cost savings (up to 90%) and the reduction in environmental and off-target impacts (Keller et al. 2014). More importantly for weed control sustainability, site-specific weed management creates the opportunity to use alternative physical weed control options that currently are not suited for whole paddock use.

Accurate weed detection allows physical weed control treatments to be applied specifically to the targeted weed. As weed identification processes develop to include weed species, size and growth stage, there exists the potential for some approaches (such as electrical weeding, microwaving and lasers) to be applied at a prescribed lethal dose. This dramatically reduces the amount of energy required for effective weed control (Table 2). For example, microwaving, as one of the most energy expensive weed control treatments as a broadcast treatment (42,001 MJ/ha), requires substantially less energy when applied directly to the weed targets (17.8MJ/ha). Therefore, even though the same number of weeds are being controlled (five plants/m2), the specific targeting of these weeds results in a 99% reduction in energy requirements.

The accurate identification of weeds allows the use of alternative weed control technologies that are not practically suited for use as whole paddock treatments. For example, lasers are typically a narrow beam of light focused on a point target. In a site-specific weed management approach with highly accurate weed identification and actuation, lasers can be focused precisely on the growing points of targeted weeds, concentrating thermal damage. By reducing the treated area of the weed, off-target losses are further reduced allowing additional energy savings.

Table 2. Total energy requirement estimates for alternative weed control options when applied as site-specific treatment. Estimates are based on the control of two-leaf weeds present at five plants/m2.

Weed control method | Energy consumption |

|---|---|

Concentrated solar radiation | 14.4 |

Precise cutting | 14.4 |

Pulling | 14.4 |

Electrocution: spark discharge | 14.5 |

Nd:YAG IR laser pyrolysis | 15.1 |

Herbicides | 14.8 |

Hoeing | 15.7 |

Water jet cutting | 15.8 |

Stamping | 16.5 |

Nd:YAG IR laser pyrolysis | 16.9 |

Microwaves | 17.8 |

Abrasive grit | 24.5 |

Thulium laser pyrolysis | 25.9 |

CO2 laser cutting | 54.8 |

Targeted flaming | 59.9 |

Electrocution: continuous contact | 60.9 |

Nd:YAG laser pyrolysis | 84.4 |

CO2 laser pyrolysis | 92.3 |

Nd:YAG UV laser cutting | 129.4 |

Hot foam | 131.3 |

Dioide laser pyrolysis | 133.1 |

Nd:YAG IR laser cutting | 204.4 |

Targeted hot water | 517.6 |

Diverse weed control – the need for both herbicide and cultural tactics

Ryegrass cross resistance and stacking HWSC with crop competition

Growers and agronomists now have a wide range of cultural tools to manage herbicide resistant weeds without compromising profit. Tactics such as HWSC, crop competition and diverse rotations are used to complement herbicide options including double knock strategies, pre-emergent herbicides and late season crop-topping. Known as the ‘big six’, these diverse weed management tactics are used in conjunction with best practice agronomy to drive weed seedbank numbers to zero.

Non-chemical tactics remain critical to controlling herbicide resistant weeds, particularly with new data emerging about cross resistance to pre-emergent herbicides in annual ryegrass. A population of annual ryegrass from South Australia (SA) has confirmed resistance to all pre-emergent herbicides – Avadex®, Arcade®, trifluralin, propyzamide and Sakura® (Brunton et al 2018). Sampled in 2014, testing by the University of Adelaide Weed Research Group showed that metabolic cross resistance was at play.

In addition, a random survey of 64 paddocks in the south-east of SA found populations of annual ryegrass with multiple cross resistance to a range of pre-emergent herbicides including Arcade®, Butisan® and Sakura®.

These findings by the University of Adelaide have huge implications for an industry now heavily dependent on pre-emergent herbicides in no-till systems, showing they can quickly break down in the face of metabolic cross-resistance. The diverse tactics outlined in the ‘big six’ are more important than ever to prevent seed set in resistant weed populations and to protect the longevity of pre-emergent herbicides for future use.

Research has shown that stacking of the ‘big 6’ tactics can have a far greater impact on preventing weed seed set than using them in isolation. Walsh & Broster (2018) highlighted that seed capture for HWSC was enhanced when combined with crop competition. A survey of 71 wheat crops across Australia showed that the more competitive crops caused ryegrass to grow upright (seeking out light) and set seed higher in the crop canopy, where a greater proportion can be captured through HWSC.

The survey found that in an average wheat crop with a biomass of 9t/ha, 74% of the ryegrass seed was retained above 10cm in the canopy. However, there was a 12% difference in ryegrass seed above 10cm between the low and high biomass crops (<7t/ha and >12t/ha, respectively) due to differences in crop competition. Narrow row spacing, vigorous varieties and/or higher plant densities all contribute to crop competition and are already recognised for reducing weed seed set and improving crop yield, but this data shows the impact they can also have on improving the success of HWSC.

Chaff lining agronomy and advances in mill technology

HWSC is becoming recognised as one of the key tactics for managing herbicide resistant weeds with growers shifting to make the practice more mainstream. Narrow windrow burning (NWB) has long held the mantle as the most popular form of HWSC, but chaff lining and chaff tramlining (or chaff decks) are rapidly gaining favour. An online survey by WeedSmart of 269 growers at harvest 2017 indicated 32% of growers were planning to use NWB, with 27% chaff lining and 12% using chaff decks. Chaff carts were stable at 12%, mill technology at 3% and 14% indicated they would not use HWSC.

The increase in adoption of chaff lining and chaff decks seems largely due to the ability to retain stubble instead of burning rows or chaff dumps. The principle involves collecting chaff and weed seeds off the main sieve to drop in a single row or split onto three metre tramlines, with real time kinematic (RTK) allowing rows to accumulate in the same area each year. Weed seeds remain on the surface where they can be grazed or left to rot, while straw is chopped and spread. A reduction in dust from the tracks when summer spraying is a huge benefit of the chaff deck system for growers in controlled traffic farming (CTF) systems.

With any new practice, there have been challenges and these have occurred either at harvest or the following season dealing with rows of dense chaff and weeds. Harvest issues have primarily involved header blockages or dust accumulation around the engine bay. Modifications with baffle and chute set-up have helped minimise issues, but with so many different makes of header, growers have had to sort many of the problems in the paddock.

Dealing with chaff rows the following season has also created issues, particularly as growers aim to promote rotting of weed seeds, while also allowing crop rows to establish and compete in the chaff line. Sowing the chaff line with a disc unit is generally preferred, along with increasing herbicide rates of pre-emergent and post-emergent herbicides over the chaff rows. Growers and their agronomists need to be aware that weed numbers can be confronting during the early years of chaff lining or chaff decks in high pressure blocks. Remember that weed seeds will be captured in following seasons and placed back on the same rows so that weed numbers and selection pressure are confined rather than spread across the paddock.

Controlling high numbers of weeds in chaff rows using selective or shielded sprayers is an option in dense populations and is well suited to CTF systems. Growers can target dense populations of weeds on tramlines while only spraying a small percentage of the paddock, e.g. two 700mm tramlines (or 1.4 metres every 12 metres) only represents 12% of the paddock. Any survivors are again picked up at harvest and put back onto the chaff rows for further treatment or rotting the following year.

Mill technology remains the ultimate form of HWSC and complements all forms of weed control. With the mill pulverising all material leaving the sieves, it eliminates the need for burning or leaving weed seeds to rot. Mills can destroy 93% to 99% of the weed seeds while spreading residue back onto the paddock without any loss of nutrients or stubble. A higher capital investment is required with mills compared to other HWSC practices, with costs ranging from $85,000 to $180,000 depending on mechanical or hydraulic drive options.

The 2018 harvest has generally been a successful season for the different types of mills available. The hydraulic integrated Harrington Seed Destructor (iHSD) operates as two hydraulically driven cage mills, while the Seed Terminator uses a mechanically driven multi-stage hammer mill. A number of concerns with the mills and their performance have been addressed by the manufacturers, following an extensive review process in 2018. Issues included excessive mill wear in sandy soils, reductions in harvest capacity and high running costs.

A new vertical iHSD mill was also released for the 2018 harvest by McIntosh and Son and the de Bruin Group. This is a mechanical drive mill with several key features including less cost ($85,000 plus GST and fitting), less moving parts, less fuel usage, less horsepower (compared to the hydraulic iHSD), an auger on the shaft to help minimise blockages, a stone trap to catch any mill destroying objects and the ability to measure harvest losses. Ten machines were running for this harvest with another 100 units sold for the 2019 harvest.

Conclusions

The emergence of annual ryegrass can be significantly suppressed with increasing amounts of chaff concentrated in chaff lines and chaff tramlines. It was only at very high rates of wheat (42t/ha) that annual ryegrass emergence was adequately controlled. The different crop species also provided different rates of reduction in emergence, although for wheat and barley the relative effectiveness varied between the three locations. Targeting treatments on individual plants such as in site specific weed management, results in significant energy savings and makes previously impractical options on a broadcast basis available for use on a site-specific basis. The opportunities here are immense for the future management of problem weeds.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC — the authors would like to thank them for their continued support.

Useful resources and references

Boutsalis P, Gill GS, Preston C (2012). Incidence of herbicide resistance in rigid ryegrass (Lolium rigidum) across South Eastern Australia. Weed Technol. 26:391-398.

Brunton D, Boutsalis P, Gill GS, Preston C (2018). Resistance to multiple PRE herbicides in a field-evolved rigid ryegrass (Lolium rigidum) population. Weed Sci. 66:581-585.

Broster JC, Koetz EA, Wu H (2013). Herbicide resistance levels in annual ryegrass (Lolium rigidum Gaud.) and wild oat (Avena spp.) in southwestern New South Wales. Plant Prot. Quart. 28:126-132.

Keller M, Gutjahr C, Möhring J, Weis M, Sökefeld M, Gerhards R (2014). Estimating economic thresholds for site-specific weed control using manual weed counts and sensor technology: An example based on three winter wheat trials. Pest Management Science 70:200-211.

The University of Western Australia - Australian Herbicide Resistance Initiative (AHRI)

Llewellyn R, Ronning D, Clarke M, Mayfield A, Walker S, Ouzman J (2016). Impact of weeds in Australian grain production: the cost of weeds to Australian grain growers and the adoption of weed management and tillage practices. CSIRO, Australia.

Owen MJ, Martinez NJ, Powles SB (2014). Multiple herbicide-resistant Lolium rigidum (annual ryegrass) now dominates across the Western Australian grain belt. Weed Res. 54:314-324.

Walsh M, Broster J, Aves C, Powles S (2018). Influence of crop competition and harvest weed seed control on rigid ryegrass (Lolium rigidum) seed retention in wheat crop canopies. Weed Sci. 66:627-633.

Walsh M, Ouzman J, Newman P, Powles S, Llewellyn R (2017). High levels of adoption indicate that harvest weed seed control is now an established weed control practice in Australian cropping. Weed Technol.31:1-7.

Walsh MJ, Newman P, Powles SB (2013). Targeting weed seeds in-crop: A new weed control paradigm for global agriculture. Weed Technology 27:431-436.

Contact details

Michael Walsh

University of Sydney

12656 Newell Highway, Narrabri 2390

02 6799 2201; 0448 847272

m.j.walsh@sydney.edu.au

John Broster

Charles Sturt University

Locked Bag 588, Wagga Wagga NSW 2678

02 6933 4001; 0427 296 641

jbroster@csu.edu.au

@JohnCBroster

Greg Condon

PO Box 73 Junee NSW 2663

0428 477 348

greg@grassrootsag.com.au

@grassrootsag

Was this page helpful?

YOUR FEEDBACK