Chemical residues/MRLs – impact, understanding and potential trade issues

Author: Gerard McMullen, Chair National Working Party on Grain Protection | Date: 10 Feb 2020

Key messages

- It is a legal requirement to follow all label directions when applying any chemical.

- Perceptions and legal/contractual requirements surrounding chemical residues differ between key domestic and export markets.

- There are market access implications when using chemicals – applying a chemical according to label directions does NOT necessarily mean that grain will meet market requirements.

- There is a need for advisors and growers to understand their markets and seek advice on the maximum residue limits (MRLs) that apply. If possible, advisors/growers should talk to marketers before applying chemicals to a crop.

What is a maximum residue limit (MRL)?

A maximum residue limit or MRL is the maximum concentration of a residue resulting from the registered use of an agricultural chemical that is legally permitted or recognised as acceptable to be present in or on a food, agricultural commodity or animal feed.

A range of different types of chemicals are applied to crops for varying reasons. Chemicals can be used before planting, during the crop growth stage or following harvest. In Australia, only those chemicals registered in Australia for use on a particular crop can be applied. It is a legal requirement in Australia that all chemicals registered in Australia be used according to label directions with regards to application rates and withholding periods.

When using chemicals, residues can remain on the harvested grain. Residues can also arise when moving grain using equipment such as augers and trucks that have previously held grain containing chemical residues.

The nature of residues arising is considered by the APVMA and, if necessary, a MRL is set for the chemical and crop commodity combination.

What are the market requirements for chemical residues?

At present, chemical residues on imported food, and food safety in general, are arguably the key focus points for markets.

When marketing grain in Australia or overseas, residue levels must meet the regulated MRL and customer contract specifications. It is important to note that the MRL specifications can differ between markets.

Each market, whether in Australia or overseas, is responsible for ensuring the food that is imported and subsequently consumed is safe to eat in terms of chemical residues. Each market has its own chemical legislation based on its own particular chemical usage and consumption patterns. Hence, different MRLs for the same chemical and commodity can apply in each market.

There is a trend towards markets developing their own chemical regulations rather than relying on international standards such as Codex Alimentarius. There is also a trend towards markets requiring lower (or nil) residues on supplied grain. Markets are also increasing their level of monitoring of imported grain via sampling and testing to check compliance with their needs.

Grain traded internationally may cause a market access issue for Australian grain where:

- The market has no MRL (missing MRL).

- The market does not apply a Codex MRL (divergent MRL).

- There is no Codex MRL for those markets that follow or default to Codex.

- The market does not have a default policy and hence a zero limit applies.

- The market applies a low level of detection (LOD).

In some instances, contracts do not state the MRLs that apply. It is the responsibility of the supplier or marketer of the grain to ensure they understand the regulations and that the grain supplied meets those regulatory requirements.

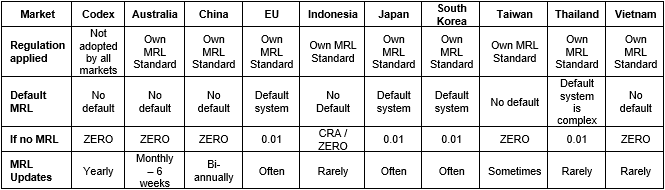

Table 1. Some key Australian markets and their chemical MRL regulations*

*Note: information as at 6 January 2020, variations exist for specific chemicals. MRLs quoted in mg/kg.

Implications for advisors and growers

Many growers do not know the market requirement before they use a chemical.

It is important to realise that while a grower can apply a chemical correctly and in accordance with label directions, the resulting grain residues may not meet market requirements.

All grain trading standards have wording in relation to chemical use that growers must comply with. An example from the Grain Trade Australia: wheat trading standards is outlined below.

Chemicals not approved for wheat (Grain Trade Australia)

A nil tolerance applies to chemicals not approved for wheat including:

- Chemicals used on the growing crop in the state or territory where the wheat was grown in contravention of the label requirements.

- Chemicals used on stored wheat in contravention of the label requirements.

- Chemicals not registered for use on wheat.

- Wheat containing any artificial colouring, pickling compound or marker dye commonly used during crop spraying operations that has stained the wheat.

- Wheat treated with or contaminated by carbaryl, organochloride chemicals, or diatomaceous earth.

- Chemical residues in excess of Australian Commonwealth, state or territory legal limits.

Residue testing is done on domestic grain and export grain shipments by either the marketer or via the National Residue Survey, which is funded through a grower levy. If residues arise that exceed the market MRL, price penalties can occur, or the shipment can be rejected and returned to Australia. Costs can be passed from the marketer to the supplier of that grain where there is evidence of chemical misuse or false chemical-use declarations. As a consequence, future grower loads and shipments can be subject to sampling and testing or additional segregations created, all of which will generate costs. These increased costs can be passed onto the grower through the purchase price offered for the grain.

The post-farmgate sector expects that growers apply chemicals following legal requirements. It is cost prohibitive to sample and test all deliveries for all possible chemicals used on-farm. Rather, targeted sampling and testing is done based on market risk. Thus, growers must provide accurate information on chemicals used on their crops. Growers are encouraged to complete ‘Commodity Vendor Declarations’ correctly when details of chemicals used are sought by the trade. Failure to do so risks supply of grain that fails to meet market requirements, a loss in reputation of Australian grain and increased costs for all along the supply chain.

Tools to assist meeting market requirements

On behalf of industry the National Working Party on Grain Protection (NWPGP) is the body responsible for providing management and leadership to industry in the areas of post-harvest storage, chemical use, market requirements and monitoring changing chemical regulations and their impact on market access.

The NWPGP is the linkage between government and industry and provides:

- Feedback on issues of concern with chemicals.

- Advice on whether government to government submissions are required.

- Strategies for dealing with changing market requirements and the industry actions required to address these.

An annual two-day conference is held providing participants with the latest research and developments in the area of post-harvest storage and hygiene, chemical usage and outturn tolerances, and international and domestic market requirements and regulations. The outcomes are provided to industry to assist with market access compliance.

In the past two years, a greater focus has been placed on providing industry with knowledge of market requirements. This has involved significant communication and liaison with the pre- and post-farmgate sectors. The gap between knowledge of the market requirements and what happens on-farm was recognised and communication to the pre-farmgate sector has increased through development of fact sheets and presentations to a range of stakeholders throughout Australia. This has occurred via both the Chair of NWPGP, the GRDC and various government departments. However further communication with grower and advisor sectors is required.

Conclusion

Given the changing nature of market regulations, all stakeholders along the supply chain need to be aware of market requirements in relation to MRLs. Given the implications of incorrect chemical use, there is a need for greater transparency and understanding by growers and their advisors of the impact of chemical use on market access.

Going forward, there will be a focus on ensuring all supply chain participants (including chemical registrants, re-sellers, agronomists, growers and their advisors) understand the risks of non-compliance with label directions.

Growers need to talk to their advisor/agronomist and storage agent/marketer and, where needed, other experts to seek advice on market requirements.

Useful resources

- On-farm Stewardship Guide ‘Growing Australian Grain’ http://grainsguide.grainproducers.com.au

- National Working Party on Grain Protection www.graintrade.org.au/nwpgp

- National Residue Survey https://www.agriculture.gov.au/ag-farm-food/food/nrs

- APVMA https://apvma.gov.au

Acknowledgement

This project is being undertaken as a GRDC-specific project and is made possible by the significant contribution of growers through the support of the GRDC. The author would like to thank growers and the GRDC for their continued support.

Contact details

Gerard McMullen, Chair, National Working Party on Grain Protection

76 Bruce Street, Coburg, VIC, 3058

0419 156 065

gerardmcmullen@optusnet.com.au

GRDC Project Code: MCM00003,

Was this page helpful?

YOUR FEEDBACK