Desiccating mungbeans - is windrowing an alternative?

Author: Jayne Gentry (DAF Qld), Cameron Silburn (DAF Qld), Paul McIntosh (Pulse Australia/Weedsmart), James Hagan (DAF Qld), Rod O'Connor (DAF Qld) | Date: 28 Feb 2023

Take home message

- Windrowing mungbeans is a viable alternative to chemical desiccation with no serious yield impact, less overall harvest losses and improved grain quality

- Windrowing may be an option in the following situations: multiple flushes of pods, hard to kill vigorous plants, pending wet weather, heavy powdery mildew infestation, accessing markets with low glyphosate maximum reside levels and growing for seed &/or sprouting

- Windrowing is not an option in the following situations: uneven ground, predicted very large amounts of rainfall, no windrowing machinery and very wet soil.

Background

Currently Australian mungbeans are chemically desiccated prior to harvest to aid in dry down of the crop to facilitate mechanical harvest. It is estimated that 90 - 95% of the crop is desiccated with glyphosate. Glyphosate is recommended to be applied when pods are black or brown (label instructions vary). Timing of desiccation is critical to ensure maximum dry down whilst minimising chemical residue in the seed. With the improvement in mungbean varieties resulting in more vigorous plants, desiccation has become increasingly problematic. Often growers struggle harvesting mungbean crops due to the moisture remaining in the stem after desiccation causing problems. Stem sap can cause seed coat staining which results in downgrading grain quality. As a result, growers have resorted to increasing rates of herbicides.

The mungbean industry must be ready to adapt if needed to meet market specifications as export markets becoming increasingly sensitive to pesticide maximum residue limits (MRL’s). To further complicate this, international markets are amending their MRL’s in very short time frames – often too slow for the industry to respond. Residues of glyphosate in mungbeans are already affecting the acceptance of Australian mungbean in some export markets. With over 90% of Australian mungbeans exported, options for alternative harvest practices that do not use crop protection products was deemed as a priority by the national industry body, the Australian Mungbean Association (AMA), in their current strategic plan.

The Mungbean Agronomy Project supported by the Queensland Government Department of Agriculture and Fisheries, the Grains Research and Development Corporation and the Australian Mungbean Association undertook research assessing the potential of mechanical desiccation of mungbeans, also known as swathing/windrowing, as an alternative to chemical desiccation. A series of commercial scale trials were implemented in 2022 which built on small plot trials conducted in 2021. Windrowing is the mechanical process of swathing or cutting the crop to form the mungbeans into a windrow which is placed onto the ground. Several days later the windrow is harvested by a header with a specialised pick-up front designed to harvest the crop off the ground. The 2021 trials successfully showed that mechanical desiccation of mungbeans was a viable method. This paper explores the results from the 2022 commercial scale trials.

Methods

15 trials were implemented, however only 12 had complete data sets due to rain. More trials were planned, however unseasonably high rainfall limited the final number. These trials were situated across southern Queensland and northern New South Wales.

Two treatments were used throughout this trial: windrowing (Figure 1) and glyphosate (Figure 2) desiccation.

Figure 1. Windrowed mungbeans

Figure 2. Chemically desiccated mungbeans

The trials established on each growers’ property were unique for every paddock to best cater for the grower’s unique machinery configuration (control traffic systems) (Table 1). As a result, each trial varied in size and sample amounts, however where possible several samples were taken for each treatment to account for as much variability as possible. Treatments were assessed via a range of parameters including grain yield, plant moisture at desiccation and harvest, and grain losses.

Grain losses were measured at various stages, using a variety of techniques, at the implementation of the treatments.

- Pre-harvest losses – Measured from the point of desiccation to just prior to harvest in the glyphosate desiccated crops only. Hessian bags were placed around the base of the mungbeans prior to chemical desiccation which captured falling seed until harvest. This measurement was assessing shattering losses during dry down.

- Swathing losses – Measured at the time of swathing (cutting). This was done using 50 x 50 cm quadrat randomly placed in the swathed area with mungbean seeds collected and weighed. This measured the losses resulting from the swathing of the crop such as shattering at the comb.

- Header losses – Measured at the time of harvest using a harvest loss system known as a Bushels Plus (Primary Sales Australia). The tray was attached to the header on the rear axle and triggered during harvest of both windrow and glyphosate treatments. This assessed loss out of the rear of the header.

- Comb losses –Measured at the time of harvest for glyphosate only treatment using hessian bags placed in the paddock. The header harvested directly over these and the seed which was on the bags after harvest was collected and weighed. This measurement assessed losses such as shattering at the reel.

- Total losses – Measured after harvest using 50 x 50 cm quadrat which was placed directly where the windrow was harvested and in a similar position in the paddock for glyphosate desiccation. This measure assessed overall losses for both treatments throughout the whole period of the crop through to after harvest. This was an independent measure.

Note: losses were extremely variable across the paddock hence were very difficult to measure accurately hence the data presented is only indicative.

Grain quality and glyphosate residue level in the seed (MRL) were also assessed.

Results

The results show that mungbeans via windrowing is a viable method (Table 1).

Table 1. Summary of results from 12 growers which had complete datasets for the respective treatments.

| Glyphosate minimum | Glyphosate maximum | Glyphosate Average | Windrow Minimum | Windrow Maximum | Windrow Average | |

|---|---|---|---|---|---|---|

Days to harvest from desiccation | 8 | 16 | 11 | 5 | 16 | 9 |

Plant moisture at harvest (%) | 19 | 47 | 31 | 13 | 27 | 19 |

Pre-harvest losses (kg/ha) | 7 | 52 | 22 | - | - | - |

Swathing losses (kg/ha) | - | - | - | 1 | 212 | 58 |

Yield (t/ha @12% moisture) | 1.00 | 4.2 | 2.13 | 1.2 | 4.1 | 1.95 |

Header losses (kg/ha) | 1 | 28 | 10 | 6 | 67 | 18 |

Comb losses (kg/ha) | 15 | 161 | 100 | - | - | - |

Total losses (kg/ha)* | 74 | 328 | 153 | 14 | 192 | 67 |

*Measured as an independent variable

Yield

On average, windrowed mungbeans showed a small yield penalty compared to glyphosate desiccated mungbeans (1.95 t/ha versus 2.13 t/ha) (Table 1), but this relationship was not consistent across all trials. Some crops achieved higher yields when windrowed, indicating the viability of the management practice when correctly implemented. The crop yields across these trials varied widely; from 1 to 4 t/ha. Although the lowest crop yield was 1 t/ha, it still had a relatively high biomass.

Days to harvest from desiccation

When directly comparing windrow and glyphosate desiccation across 12 grower sites with complete data sets, windrowing mungbeans had the benefit of a shorter period to harvest by at least three days (Table 1). Due to trial and harvest logistics, harvesting of the windrow didn’t occur at the optimal time in several cases. The majority of the windrows could have been harvested within the 4–7-day window, potentially halving the time to harvest compared to glyphosate desiccation. The earlier harvest with windrowing was possible due to the rapid dry down of plant material; windrowed plant moisture was 19% at harvest compared to glyphosate which was 31% (Table 1). This was also a similar trend in the 2021 small plot trials at DAF Hermitage research station (data not shown). Three days post windrowing the plant moisture had almost halved and continued a rapid decline. It wasn’t until 14 days after desiccation that glyphosate treatments reached a similar plant moisture level compared to windrowed treatments.

Grain losses

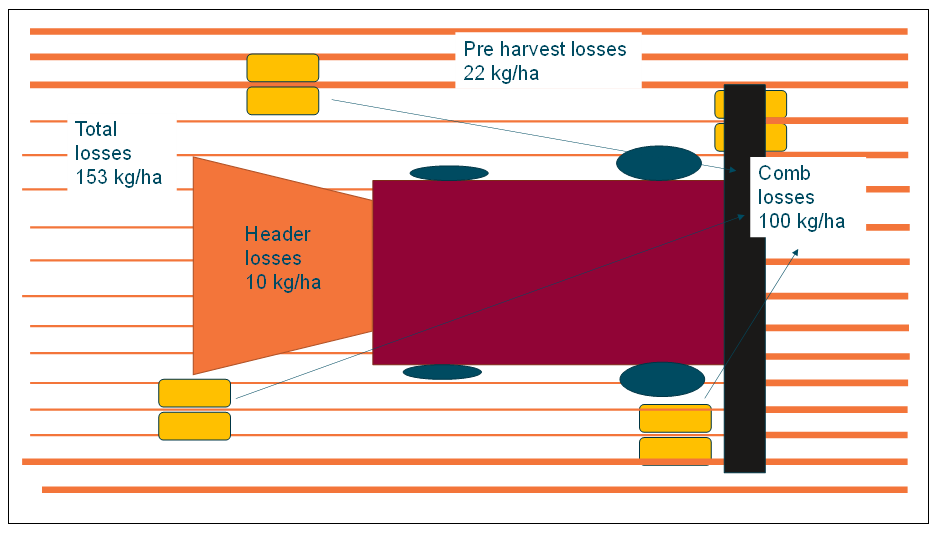

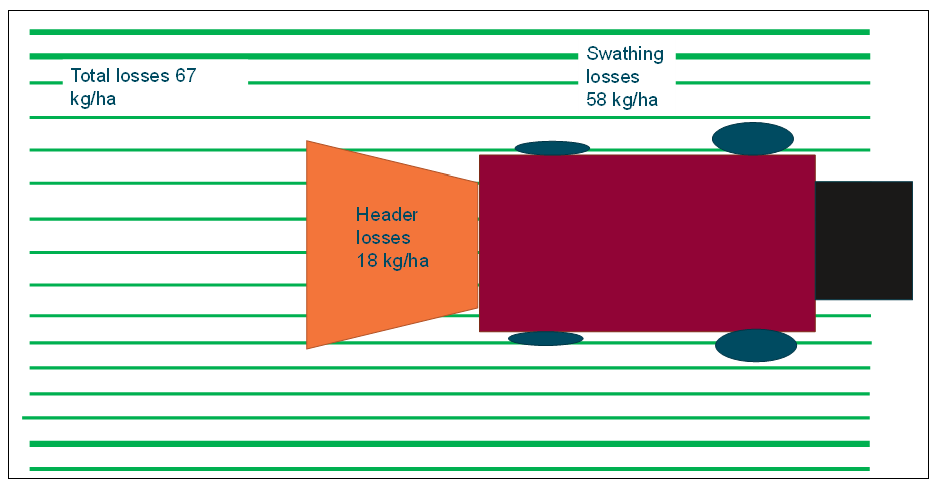

Grain losses were measured at various times across the process from desiccation to harvest (Figure 3 and 4). Total losses (measured as an independent variable) were lower in windrowed mungbeans compared to glyphosate desiccated mungbeans (Table 1). Average loss for windrowed treatments was 67 kg/ha compared to 153 kg/ha for glyphosate desiccated mungbeans. The highest loss of 328 kg/ha for glyphosate desiccation was a result of delayed desiccation due to rain.

Swathing (i.e. the process by which the mungbeans were cut and thrown into a windrow) losses for windrowed treatments measured the loss which occurred during the swathing process (Figure 4). Results showed a loss of 58 kg/ha on average and ranged from 1 to 212 kg/ha (Table 1). The swathing losses between sites varied due to weather conditions and swathing machinery. The trials with lower swathing losses were achieved by swathing when conditions were more conducive i.e., when the mungbean pods were still slightly soft in hand. When these conditions were met, swathing losses were below 30 kg/ha. The highest swathing loss of 212 kg/ha was recorded in a trial on a flood irrigated furrow system. The mungbean plants were leaning over into the furrow and the swather wasn’t set up correctly (with crop lifters) to capture these pods which were below the machine’s sickle bar. When removing this site from the results, the average swathing losses reduce to 43 kg/ha.

Figure 3. Diagram of harvest losses when harvesting glyphosate desiccated mungbeans

Figure 3. Diagram of harvest losses when harvesting glyphosate desiccated mungbeans

Figure 4. Diagram of harvest losses when harvesting windrowed mungbeans

Grain quality

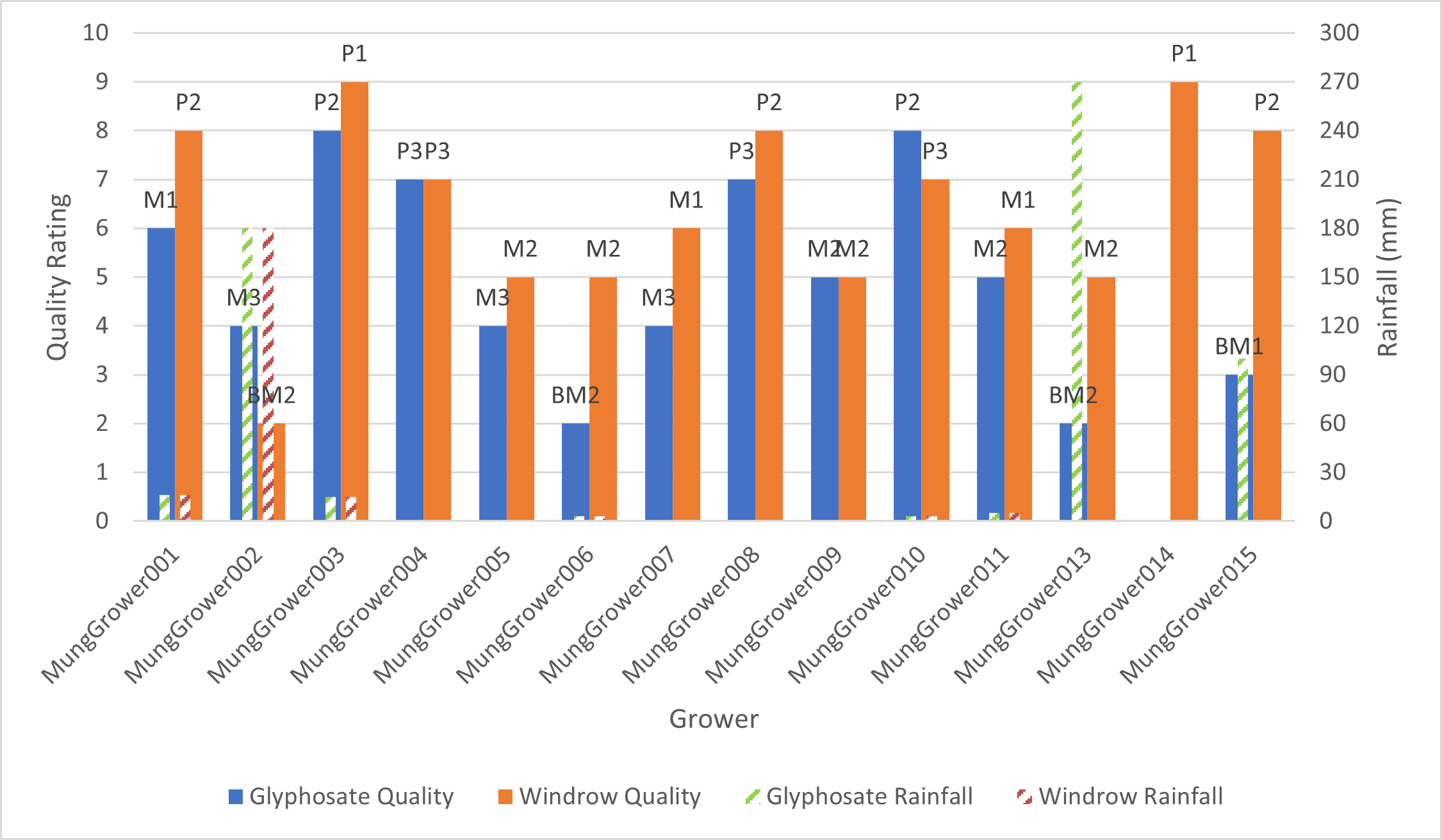

Mungbean grain quality was variable, however, most trials were manufacturing grade and above(Figure 5, Table 2). Generally windrowed crops achieved higher quality levels (10 out of 15 higher and 2 out of 12 with the same). These trials showed that moderate falls of rain on the windrowed treatments, no more then 25- 50 mm, didn’t have a serious impact on mungbean quality and harvestability. There was rain of approximately 15 mm in two crops (MungGrower001, 003) and in both cases the windrowed treatment had better quality mungbeans. However, extreme weather events of more than 100 mm, resulted in complete loss of the windrowed mungbeans and severe quality downgrades for both treatments (MungGrower002). In the case of MungGrower013, 014 and 015, windrowing enabled the crop to be harvested before rain due to faster dry down and no withholding periods resulting in a large increase in quality (Figure 5). Mungbeans deemed below manufacturing (BM) made this level due to large amounts of rain e.g., more than 100 mm post desiccation.

Figure 5. Quality rating for glyphosate and windrowed mungbeans. Dashed bars represent rainfall between desiccation and harvest. Letters and number on top of bar represent grain quality rating.

Table 2. Grain quality rating scale conversion table from commercial code to number code.

Rating scale | No. rating scale | |

|---|---|---|

P=Processing | P1 | 9 |

P2 | 8 | |

P3 | 7 | |

M=Manufacturing | M1 | 6 |

M2 | 5 | |

M3 | 4 | |

BM = below manufacturing | BM1 | 3 |

BM2 | 2 | |

BM3 | 1 |

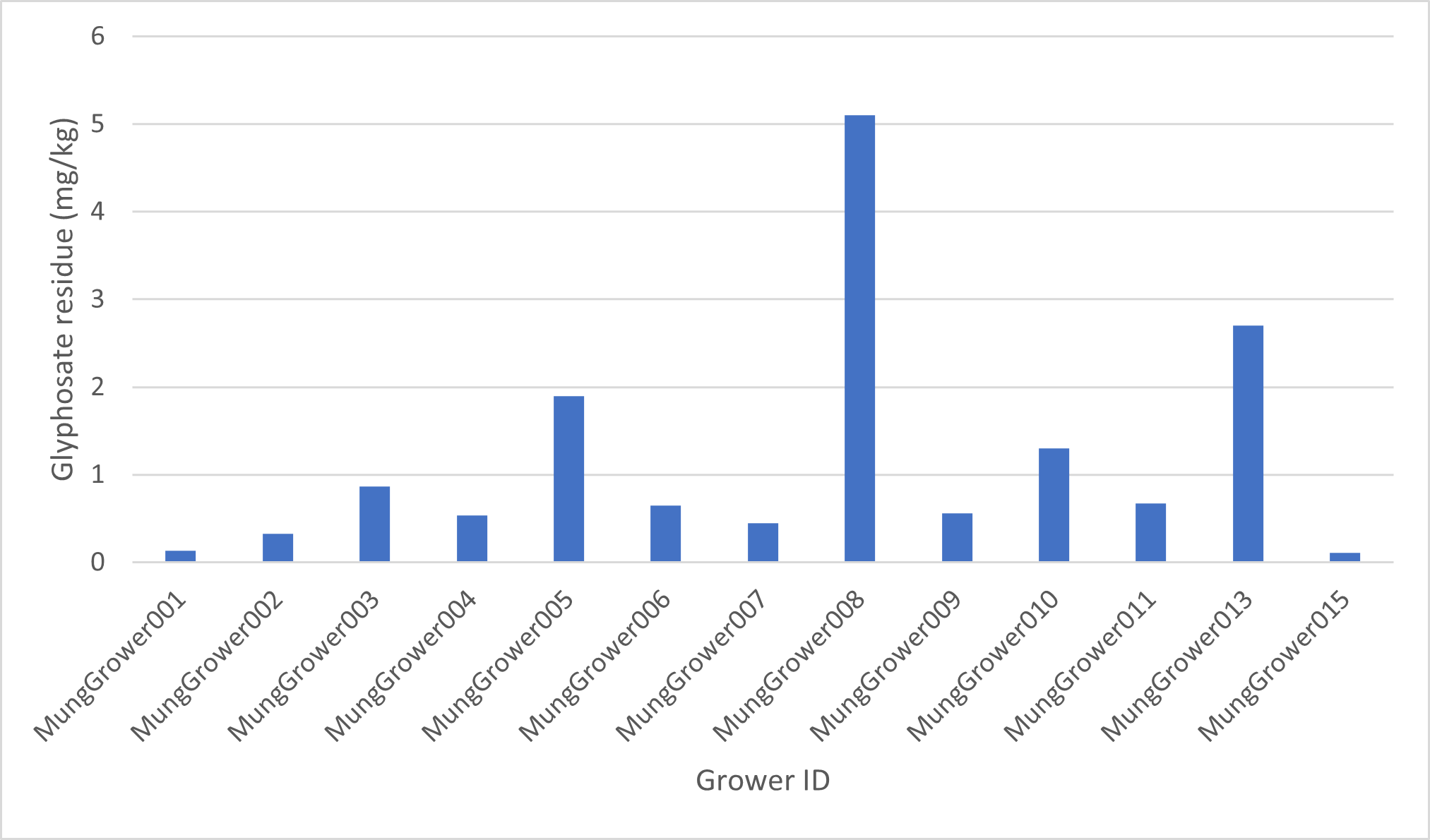

Glyphosate desiccated treatments were tested for glyphosate residue in the harvested seed. All samples recorded glyphosate, however, all were under the Australian maximum reside level (MRL) of 10 mg/kg (Figure 6). Individual countries set their own MRLs. For example, Taiwan currently has the lowest MRL of 2 mg/kg. Only two crops recorded over this MRL (MungGrower008 and 013), 5 mg/kg and 2.7 mg/kg respectively. MungGrower008 most likely had a higher percentage of green and immature pods at the time of glyphosate desiccation resulting in translocation of this chemical into immature seeds.

Figure 6. Mungbean grain desiccated with glyphosate residue levels (mg/kg)

Gross margins

Partial gross margins were calculated comparing the cost of implementation of the treatments (Table 3):

- Glyphosate 570 g/L (highest label rate of 1.7 L/ha)

- Windrowing

- Diquat 200 g/L (highest label rate of 3 L/ha)

These calculations indicate that windrowing mungbeans costs approximately $13/ha more than glyphosate desiccation, however, half the cost of a full label rate of diquat. Considering seed crops and crops for the sprouting market are recommended to be desiccated with diquat (as glyphosate reduces germination) – windrowing may be an option purely based on profitability.

Table 3. Cost estimates for mungbean desiccation

Treatment | Costs 2022 |

|---|---|

Glyphosate 1.7L/ha | $29.20 |

windrowing | $42.05 |

diquat 3L/ha | $83.40 |

2022 Assumptions: 12 m Swath, 7 km/hr Swathing speed, $14/L glyphosate, $26/L diquat, 36 m boomspray, 15 km/hr spraying speed, $1.8/L fuel. | |

Further, an increase in quality of the mungbeans e.g. from manufacturing to processing would increase the price paid by marketers by $50 to $100/t. Considering these crops were on average over 2 t/ha this represents a large increase in gross margin, more than covering the extra cost of windrowing.

Conclusions

Growers can have the confidence to successfully harvest their mungbean crops by windrowing. Windrowing has two major benefits over glyphosate desiccation; faster dry down and no potential glyphosate residue. Other benefits of windrowing include potential for earlier desiccation and harvest, easier threshing, no sap staining, and better grain quality. The results of these on-farm commercial strip trials also showed that there are fewer overall losses from windrowed mungbeans, and yield is similar to glyphosate desiccated mungbeans.

However, windrowing mungbeans involves more costly operations with two slower passes (swather and header). The requirement for specialised machinery is a major limitation to windrowing. Swathers and pickup fronts are not common pieces of machinery in Queensland; hence this is the biggest barrier to adoption of mungbean windrowing in Queensland. In NSW, it is suspected that this would be less of a barrier due to more availability of this specialised machinery which is also used for canola harvesting.

Mungbean regrowth post windrowing could add to the cost as a post-harvest spray. However, depending on rainfall patterns, a post-harvest fallow spray is likely to be required regardless. Participating growers in these trials felt that they would rather spray regrowth post windrow harvest compared to desiccating mungbeans with glyphosate, as there was no risk of chemical translocation to the seed. Spraying regrowth mungbeans also gives far greater flexibility to use herbicides with various modes of action.

Timing of harvest operations and harvester set-up is critical to minimising harvest losses across both techniques. Timing windrowing is not as critical as it is for chemical desiccation as there is no risk of chemical translocation. It is recommended that windrowing occur when ~90% of the pods have reached physiological maturity. The mungbean crop needs to be cut earlier in the day when pods are ‘doughy’ in hand or crop isn’t as mature. If the pod is crispy and shattering in hand i.e., late in the afternoon, this will result in high swathing losses.

Growers need to be aware of the rapid dry down of windrowed mungbeans and time pickup accordingly. This research was carried out in relatively mild conditions from April to June. If mungbeans were windrowed in hotter summer conditions, for example January and February (30oC plus days), dry down could be as short as 2-3 days. Harvest losses may be reduced by picking-up early in the morning whilst there is still moisture on the crop. If the crop is too dry, harvest losses can be significant. In comparison there is a withholding period of seven days prior to harvest of glyphosate desiccated mungbeans.

Once the mungbean crop has been swathed and put into a windrow, it can tolerate small amounts of rain, of up to ~50mm. In contrast, large amounts of rain and very wet ground can result in mould and reductions in yield and quality. Growers also need to be aware of ground surface moisture which can result in the swather or pick-up front also harvesting smalls clumps of dirt. This will directly impact mungbean quality.

Spraying glyphosate earlier than recommended prior to physiological maturity, may result in translocation of the chemical to the seed. This translocation to immature seeds will result in detectable levels in these seeds which may have implications for marketing. Ensure you discuss with your marketer prior to desiccation. Minimise glyphosate seed residues by accurately assessing physiological maturity and not desiccating immature crops.

It is still uncertain how successful windrowing would be in low biomass crops, as this research was conducted on crops with high biomass.

Mechanical desiccation may be an option in situations when:

- Multiple flushes of pods

- Hard to kill vigorous plant

- Pending wet weather (i.e., in 7-14 days)

- Heavy powdery mildew infestation when glyphosate can’t be taken up by the plants

- Accessing market with low glyphosate MRL e.g., Taiwan

- Desiccating crops for seed &/or sprouting market.

Mechanical desiccation is not an option in situations when:

- Uneven ground e.g., flood irrigated mungbeans with large furrows can result in very high losses. Set-up needs to be seriously considered to minimize losses

- Very large amounts of rainfall are predicted

- No machinery available

- Very wet soil as this will result in wheel tracks and compaction

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support. Further thanks to the Australian Mungbean Association for both their funding and support of this research.

Finally, this research would not be possible without a team of dedicated research and technical staff, specifically Cameron Silburn who drove this research and spent many days on the road following harvesters across southern Queensland.

Contact details

Jayne Gentry

Department of Agriculture and Fisheries

Toowoomba

Ph: 0428 459 138

Email: Jayne.gentry@daf.qld.gov.au

Date published: March 2023

GRDC Project Code: DAQ1806-003RTX,

Was this page helpful?

YOUR FEEDBACK