Spray application manual

10 June 2025

Module 21: Assessing spray deposits

21.5 Water and oil-sensitive paper

Published 24 January 2025 | Last updated 20 January 2025

Water sensitive paper (WSP) is a resource that has been available to spray applicators for many years. WSP is thick paper with a special coating that produces a stain when a droplet lands on it, which allows spray applicators to assess spray deposits.

Water-sensitive paper illustrating various spray qualities at the same application volume

Consider where to place WSP in the paddock. Often WSP will be place on the ground to measure horizontal coverage, however if your spray target is a small vertical target (i.e. 1-2 leaf grasses) then also position cards vertically against the direction of travel and check coverage on the front and back of the card.

Figure 2 Position WSP horizontally and vertically to understand coverage on small upright capturing surfaces.

Figure 3 This level of coverage may be adequate for the horizontal capturing surface, but may be inadequate for the vertical capturing surface (i.e. a small grass weed)

Figure 4 An example of coverage of droplets on the rear facing vertical card (left picture, 2% spray coverage), front facing vertical card (middle picture, 3.1% coverage) and horizontally placed card (right picture, 15.4% coverage) from an application applied to bare soil with no stubble coverage and a medium to coarse spray set up applied at approximately 16 kph and 50cm boom height.

While somewhat difficult to see with the naked eye, the droplets on the rear facing card are the very small end of the droplet spectrum that can wrap around the obstruction. This example was applied by a hand boom with no wind, allowing these small droplets to reach the capturing surface. Under conditions of a cross wind, high boom height, fast travel speed, high delta T conditions, or if a larger droplet spectrum was selected, these very small droplets are unlikely to reach the target at all.

Before the advent of image-analysis tools that could read WSP, spray applicators relied on visual assessments of the spray deposits and basic counts of the number of droplets per square centimetre (droplets per cm2) landing on the cards to be able to compare spray set-ups. While this is useful for determining if spray is depositing where it is required, it does not always provide a useful measurement for determining which set-up may be providing better coverage.

The difficulty with counting droplets per cm2 to determine if spray coverage is adequate is that it is only useful to compare similar droplet sizes, e.g. a medium spray quality with a medium spray quality. It becomes much more difficult to usefully compare 40 coarse droplets per cm2 to 40 medium droplets per cm2, as the amount of product deposited onto the target can be totally different.

Assessing the percentage covered on the WSP allows comparisons between different spray qualities and droplet sizes to be made, provided the WSP is placed where the droplets need to land and that the droplets themselves are able to deposit and remain on the WSP as they do on the intended target.

Find out more

For more information: Water sensitive paper can be purchased through Trial Supplies Trial Supplies or many nozzle or spray application equipment suppliers

WSP is available in several sizes and the most common size used is 76 x 26 millimetres, which comes in a pack of 50. The purchase price may be up to $2 per card (depending on where they are purchased), so it is important to plan how you are going to use them.

Measuring spray coverage on WSP using the SnapCard app

There is a lot of information that can be collected by taking measurements of spray coverage in the field using WSP, so spray applicators need to think about not only the comparisons they wish to make, but also how to measure, record and store the data they obtain.

Collecting a set of benchmarking data is a good place to start. Collecting spray coverage data based on how sprays are currently applied provides a basis for comparison when considering making changes to parameters in the future, or if the results highlight poor coverage for certain spray jobs.

Many growers have started to develop spray application guides for their own machine, photographing the WSP cards and recording the percent coverage for each set-up they use, as well as recording the impact of changing parameters such as pressure, application volume or travel speed. Over time this information becomes a valuable tool, especially when the information in the spray records allows for direct comparison between how the application was made and the results that were obtained.

The SnapCard app

The SnapCard app is the outcome of a research collaboration between the Department of Agriculture and Food, Western Australia, entomology group and the University of Western Australia’s applied entomology program that was supported by funding from the Council of Grain Grower Organisations.

The SnapCard app has been available as a downloadable app for both Android and IOS devices since 2014, and its use by growers and spray operators to measure spray deposition has continued to increased.

The SnapCard app has many useful features that spray operators can use to predict and measure spray coverage on WSP. Predictions in the app are based on agronomic variables, weather conditions and sprayer set-up and serve as a useful guide to compare actual measurements with. But its most powerful function is the measurement tool, which provides the user with a measurement of the percentage of WSP covered.

Find out more

The SnapCard app can be accessed from https://www.agric.wa.gov.au/grains/snapcard-spray-app

Accuracy of the SnapCard app

In a recent University of Queensland study comparing some of the image-analysis systems available to measure spray deposits. Results obtained from the SnapCard app were in general agreement with larger, laboratory-based equipment, which is often expensive and difficult to use in the field.

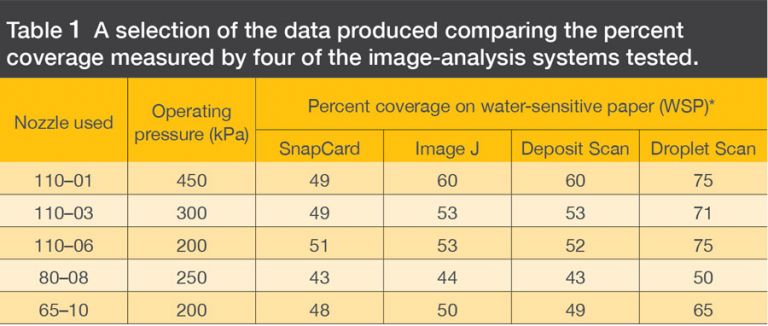

A selection of the results obtained from this study (Table 1) shows the percent coverage on WSP as measured using a range of image-analysis systems. The nozzles and operating pressures used in this study were the American Society for Agricultural and Biological Engineers (ASABE) reference nozzles, which determine the spray quality classification for nozzles according to the standard ASABE S572.1.

While the estimates of percentage coverage measured with SnapCard were marginally lower for the 110-01 nozzle outputs than those measured by other instruments (Table 1), there was strong agreement with other instruments for the range of droplet sizes that are likely to be used by Australian grain growers.

A selection of the data produced comparing the percent coverage measured by four of the image-analysis systems tested.

Tips for getting the best results with WSP using the SnapCard app

Download the SnapCard app

WSP is available through Trial Supplies, several nozzle suppliers and some machinery dealers.

Always use disposable gloves when handling WSP as fingerprints can produce a stain on them.

Do not use WSP when the relative humidity is above 70 to 80 per cent, as the cards will turn blue. Place out a single test card to assess this before starting any trial.

Consider the position of the WSP cards in relation to the sprayer. It is a good idea to set an A–B line for the sprayer, or use established wheel tracks, and then place pegs in the ground where the cards are located. Even in fallow the WSP cards can be hard to locate.

Place several cards out at each location you wish to collect coverage data from. After the measurements of spray coverage are completed, record an average for the group of WSP cards at that location.

Allow the cards to fully dry before collecting them.

Label the back of each card with a pencil for future reference and store them separately in snap-seal bags to avoid exposure to moisture or humid conditions.

After collecting all of the WSP cards, go to a place out of the wind where you can use SnapCard to capture images of the WSP cards and record all the results at one time, keeping the smartphone camera at a constant distance from the WSP cards, and under uniform light conditions.

Once all the WSP cards have been measured with the SnapCard app, they can be photographed or glued to a sheet of paper and scanned. It is a good idea to include details of each treatment and the sprayer set- up used in the photograph or scan. WSP cards that have been exposed to atmospheric humidity cannot be stored indefinitely, so make sure all photographs and measurements are done on the day of application. Unused WSP cards not protected from humidity may turn blue/green within days of opening the sealed foil packet and then can no longer be used.

Keep the results of all of your tests in one book or folder for future reference, making sure you record all of the application parameters and conditions for each test.

Situations where assessing spray coverage with WSP can identify areas of improvement

Many applicators may not have considered the number of situations where an accurate measurement of coverage could be useful for improving the sprayer set-up. While the following examples may not include every possible use of WSP, they do provide a useful guide for how to look at specific situations.

Assessing penetration into crop canopies

Placing WSP cards directly onto the crop canopy using staples or paper clips at various heights throughout the canopy can demonstrate how much penetration into the canopy can be achieved using different application parameters.

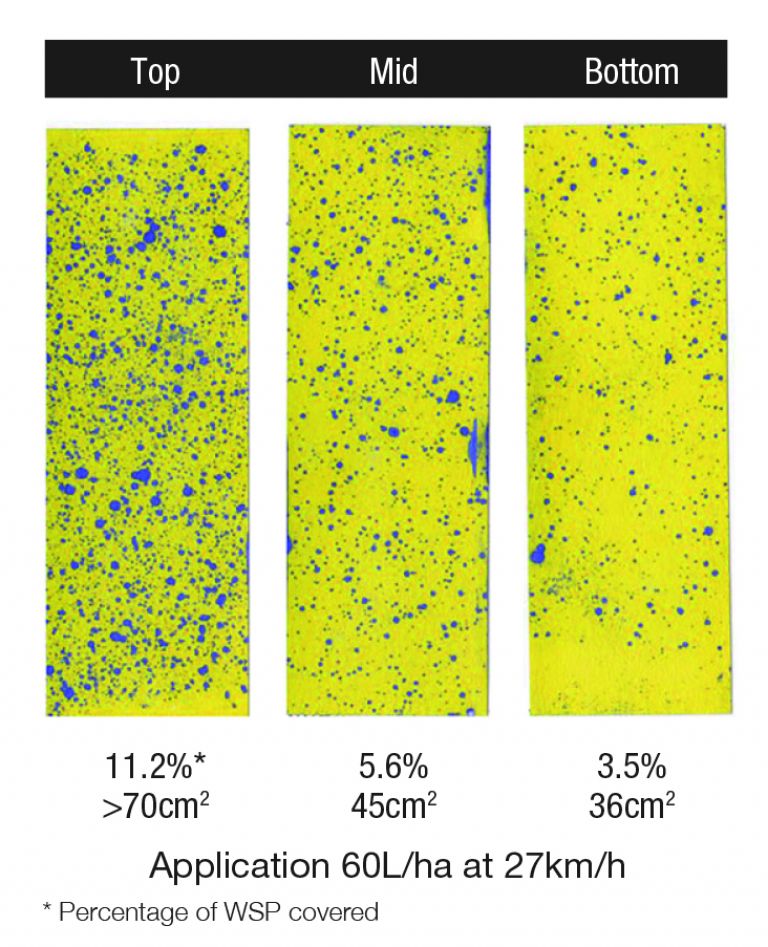

The images in figures 2 and 3 and 4 and the summary in Table 2 are from an example of using WSP and the SnapCard app provided by Bill Campbell of Farmanco Consultants in Western Australia. Figures 2 and 3 show the difference in coverage on WSP cards that a change in spraying speed with the same nozzles can produce in a late canola canopy, with the results summarised in Table 2.

Deposits onto WSP cards at three locations in the canopy (top, mid and bottom).

Deposits onto WSP cards at three locations in the canopy (top, mid and bottom).

Summary of spray coverage at three positions in the canopy (top, mid and bottom) at two spraying speeds.

Assessing spray deposits into standing stubble

To assess if the sprayer is set up to provide good spray deposition into standing stubble requires a comparison to be made between the spray deposits in the inter- row space and at the base of the standing stubble (within the stubble row). If a sprayer set-up can produce good spray coverage that is equivalent between the two locations, it generally indicates that the spray operator has selected an appropriate spray quality and application volume for stubble load and the spraying speed tested.

Placement of water-sensitive paper for assessing fallow sprays

For pre-emergent herbicides that bind tightly to stubble and cannot be washed off with rainfall (e.g. trifluralin) the spray droplets need to directly reach the soil to obtain satisfactory weed control. To access soil coverage, WSP should be place on the soil surface and under any stubble on the soil surface (ideally both in the stubble line and in the interrow). For good herbicide efficacy, target approximately 15-20% coverage of the WSP. If stubble interception prevents this from being able to be achieved by modifying application setup, then users should consider stubble removal before applying herbicides with strong stubble binding such as trifluralin.

Assessing deposition in fallow & wheel tracks

15 January 2025Assessing spray deposition in fallow and wheel tracks. Another video from GRDC's Spray Application GROWNOTES™ series.

This video appears in modules 4 and 21.

Bill Gordon: We're looking at assessing spray deposition in stubble, particularly in summer time because one of the issues we have on most machines is problems in the wheel tracks and issues with dusting around the wheels, so what we've been doing is positioning water sensitive paper down in amongst the stubble, but also in the inter-row. It's important to have a reference point when you do that, so when checking across the machine we'll start out on the boom and see what the deposition should be without interference, and then we'll come back into the machine.

So what we'll do is check some deposition in the standing stubble out on the boom here. Okay we're about the midpoint of the boom out from the machine, and we placed the cards in the inter-row or between the standing stubble but also at the base and what we're looking for is comparing the deposition between the two areas, so looking at where the droplets have landed, seeing if there's enough coverage there we're going to use this as a reference point. The things we're looking for on this water sensitive paper or card is how even that is between the two. If we get to the point where these are pretty even it's a great reference point, so on this we can see fairly uniform droplets, you actually use the core spectrum here at about 80 litres of water and the two cards look very similar.

Now we can use at base programs like snap card to actually measure that deposition as a percentage coverage and we can see how close it is, cos quite often with the naked eye they'll look similar but you might not pick up the subtle differences, but these two to me look pretty even and they'll form our reference point for comparing the other cards in closer to the machine, so whatever happens here out on the boom we'll be comparing other parts of the boom particularly around the wheel tracks in the center of the machine to see if it is as good as it is here. Now if we see any issues between these, like differences between what's happening in the inter-row and the stubble line, particularly reductions in the stubble, that should be a cue to us that we need to change something either volume or pressure, maybe manipulate droplet size a little bit, so this is our reference point. If we get this right across the boom then we can go and have a look at the center and see if there's anything also we need to adjust to tweak the wheel tracks or manipulate for dust.

We're moving into the wheel track area of the machine now and it's really important focus for summer fallow spraying, not only for dust but looking at what's going on around the wheel track, so we're looking at either outside the wheel or inside the wheel and coming down to the cards, this one placed on the outside of the tyre, so we're comparing what's going on in the inter-row to the standing stubble and I can see in the standing stubble on the outside of the tyre the deposition is quite a bit lower on this card. If I come to the inside of the tyre over here, again if we look at what's going on here in the standing stubble you can see the deposition is a lot less there in the standing stubble, so what we're going to do is have a look at the setup on the machine, see where the nozzles are and see if we can make some improvements.

We come in to look at the nozzle setup on this machine, I can see it's a dual boom and that in and around the wheel itself they've actually got a larger nozzle on here to increase the flow rate, which is very common for most operators, they'll increase the flow on the wheel to try and deal with dust and wheeltrack issues, but what we've seen is that the problem is actually also on the outside of the wheel, so rather than just increasing the flow rate in one spot by in this case including a bigger nozzle, what we should do is probably spread that flow, at least look at outside of either side of the wheel to try and even up that deposition and then run those tests again to see how well we've done.

Once we've done that we can look at other areas on the machine, so while we're doing the same test, I tend to not only focus on the outside of the boom or in the wheel tracks, I'll take a measurement in the center on these particular wheels inside and outside on the other wheel and also out on the center of the boom and make the same comparisons. Remembering that our reference point is what's going on out in the boom, if we see any differences in the center around the wheels this is where we're trying to improve things to get our fallow spraying to be a little bit better.

Determining wake effects and wheel-track issues

Placing WSP cards at different positions across the boom sprayer allows spray operators to look at the impact of changing travel speed on the amount of spray that deposits in the centre of the sprayer, adjacent to the wheels and out under the boom. This information is useful for looking at wheel-track issues and adjustments that can improve coverage.

Generally, when the spray deposits onto the WSP cards located in the midpoint of the boom are similar between the inter-row and the base of the stubble, the operator has selected a useful spray quality. If this has been achieved, then the depositions at other locations can be assessed.

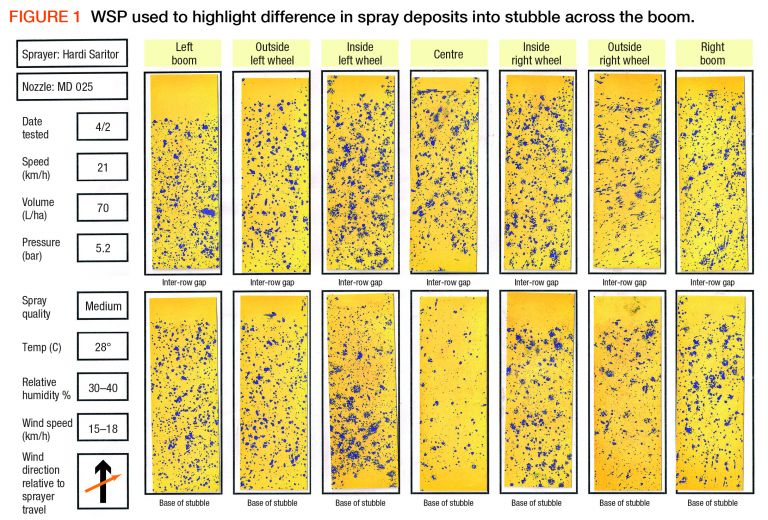

Figure 5 shows the spray deposits onto WSP across the boom for a Hardi self- propelled sprayer travelling at 21 kilometres per hour. The upper row of WSP cards show the deposition into the inter-row gap, and the lower row of WSP cards show the deposition at the base of the stubble at the same locations.

WSP can be used to highlight differences in the spray deposits into standing stubble at different locations across the sprayer

Placing water-sensitive paper cards in the inter-row and at the base of the standing stubble can highlight areas of poor deposition due to the wake effect. Figure 5 shows poor deposition in the centre of machine at base of stubble resulting from small droplets being transported upwards behind the machine.

Note that the deposition under the left and right booms is very similar for the base of the stubble and the inter-row, and that the coverage obtained with the Minidrift 025 is very good at 70 litres per hectare. However, we can also see that the coverage at the base of the stubble in the centre of the machine is lower than other locations.

This can indicate that the travel speed may be creating a wake effect behind the sprayer, displacing some of the smaller droplets. Where this effect is visible, it would be advisable to conduct another test at a lower spraying speed (maintaining a similar droplet size and pressure), or in a different direction of travel to see if the problem still remains.

Evaluating the impact of duty cycle on spray coverage with pulse width modulation

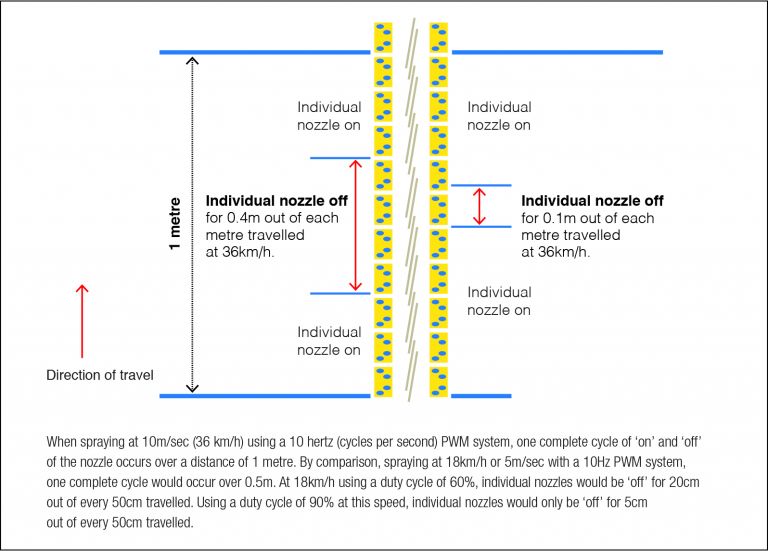

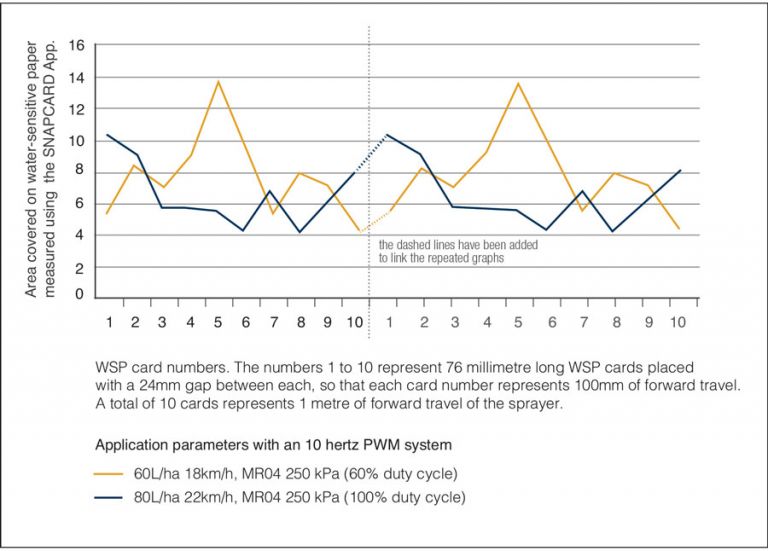

Placing the 76mm-long WSP cards at regular intervals, usually with a 24mm gap between them, onto strips of timber that are at least one-metre long can highlight possible coverage concerns if the duty cycle of a pulse width modulation (PWM) system is too low to provide even coverage.

Placement of water-sensitive paper to evaluate the impact of low duty cycle for PWM systems

Aligning the strips of timber with the direction of travel and spraying at different speeds can show the impact of low duty cycles, particularly with coarser spray qualities. Figure 7 highlights the potential impact on spray coverage that can occur due when the duty cycle of a PWM system is reduced and the droplet size is large (e.g. a coarse to very coarse spray quality).

Representation of spray deposits from a single nozzle onto water-sensitive paper

Note that the distance travelled for one complete cycle of ‘on’ and ‘off’ will change if the PWM system is designed to operate at a higher frequency (cycles per second) or hertz. Many older systems operate at 10 hertz, whereas newer systems typically operate at 15, 30 or even 100Hz. For a 30Hz system the distance travelled for one complete cycle will be three times less than a 10Hz system, this offers the opportunity for improved coverage and fewer potential ‘skips’ or misses.

Figures 7 and 8 show the results of actual measurements of area covered on WSP cards using the SnapCard app for two passes of a 10Hz PWM system, one at 60L/ha (60 per cent duty cycle) and the other at 80L/ha (close to 100 per cent duty cycle).

The area covered on water-sensitive paper, aligned with the standing stubble

At duty cycles between 50% and 100% peaks and troughs in deposition can occur aligned with the direction of travel. While deposition is more even with the sprayer at 100% duty cycle in the example above, the overall deposition is lower, impacted by the higher travel speed and interception of droplets by standing stubble, despite the higher water rate used.

Where nozzles producing a coarse spray quality or larger are used, there is less blending of spray between adjacent nozzles, which can highlight skips (area of low spray coverage) when flow to the nozzle is off, due to a lower duty cycle.

Identifying suitable spraying speeds and sprayed widths for target-selectable sprayers (also known as optical spot sprayer technology (OSST)

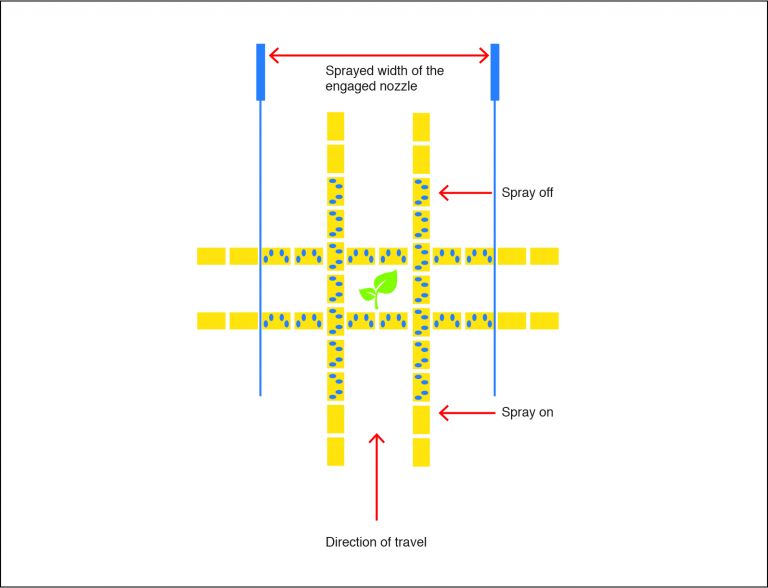

There are two simple checks the operator can do to evaluate the set-up of a target- selectable sprayer: one is to look at the timing of sprays turning ‘on’ and ‘off’ in relation to the target and spraying speed; the other is to look at the sprayed width at various travel speeds and operating pressures.

Water-sensitive paper placement for assessing target-selectable sprayers.

Placing cards on strips of timber aligned with the direction of travel can quickly illustrate when the individual sprays turn on and off in relation to the position of a weed for target-selectable sprayers.

Using the same type of timber strips, with WSP cards aligned perpendicular to the direction of travel (parallel to the boom) and the centre of the strip aligned with the weed, can show the actual sprayed width when the machine is operating at its usual spraying speed.

A number of product labels include a spot spray rate (rate of product per 100L of water) that may be used when application is made through a target-selectable sprayer. If a spot spray rate is not included on the label, and the applicator elects to apply the product at the litres-per-hectare rate with only a single nozzle firing over the target, then an even fan nozzle will be required and the rate will need to be calculated based on the width of ground cover, being a factor of nozzle fan angle, pressure and nozzle height.

To calculate the applied rate based on the sprayed width:

Litres per hectare = litres per minute per nozzle x 600 ÷ sprayed width per nozzle (in metres) ÷ speed (km/h)

Find out more

For more information go Module 20 Optical spot sprayers or Module 8 Calibration of the spray system.

Placement of water-sensitive paper to test the sprayed width for a WeedSeeker®

Often when testing the spray coverage of target-selectable sprayers it is useful to ensure the area for the trial is free of any green vegetation that might trigger the cameras, and to deliberately transplant weeds into the test area.

When the spraying speed is not appropriate for the nozzle type or timing, the spray droplets will deposit onto the WSP cards well before or well after the position of the weed.

Spray coverage obtained when the wrong nozzle is fitted to a target-selectable sprayer