Spray application manual

4 June 2025

Module 17: Pulse width modulation systems

17.4 Nozzle orifice sizes

Published 24 January 2025 | Last updated 20 January 2025

Suitable nozzle types for PWM systems

Nozzles that can be operated on PWM systems are limited to nozzle designs that are not adversely impacted by the rapid on and off cycles utilised to control the flowrate.

The most common nozzle types fitted to PWM systems are standard or extended range flat fans or versions of pre-orifice nozzles (for more information on the various types of nozzles available refer to Module 3 – Nozzle design and function).

While some nozzle manufacturers will support the use of specific air inducted nozzle models and orifice sizes on selected PWM systems, many manufacturers of PWM systems have not recommended the use of air induction nozzles on their systems.

Air induction nozzles (which rely on a venturi to create the spray pattern and to control the droplet size) may not operate effectively when fitted to PWM systems particularly at low duty cycles (below 30-40 percent) with lower pulse frequencies (typically less than 20-30Hz).

The narrow range of operating pressures for some PWM systems may also limit the choice of nozzle models due to spray quality requirements of the products being applied.

Always refer to the PWM system manufacturer’s recommendations for suitable nozzle types, models and operating pressures for their PWM systems.

Nozzle selection and duty cycle for pulse width modulation

24 January 2025Nozzle selection and duty cycle for pulse width modulation. Another video from GRDC's Spray Application GROWNOTES™ series.

Bill Gordon: Ok one of the things I want to talk about when it comes to pulse width modulation or any system that actually runs a solenoid that opens and closes very quickly, is a style of nozzles that we're going to run on it and our choices and how that operates in conjunction with that duty cycle or the speed at which this opens and closes. So when we open and close a solenoid very quickly, we have difficulty running things like air induction nozzles.

You have to run specialist pre-orifice, a bit like your low drift types or standard flat fans on these, and you can see on this one we actually have a model number it's an 05 orifice, now for most of growers you know that might be running in the mid twenties they might choose an 025 or an 03 nozzle. If i put an 05 on there that means the percentage of time this is going to be on it's not going to be running continuously or a hundred percent of the time, so if I'd normally run an 025 and I put an 05 orifice on there it's going to be running about fifty percent of the time. That's one of the issues that we find with these is that if you put too big a nozzle on here that duty cycle or percentage of time that it actually stays open gets too low, so nozzle selection becomes very critical.

Now with this particular system you can run Wilga nozzles, but you also have the option to buy retro fitted caps and run T jets on. Like any other system you need to check that 1: it's going to give the litres per hectare, 2: it's going to give you the droplet size or spray quality you require, but the 3rd thing you need to think about with these systems and I can't emphasize that enough, is the percentage of time that it's going to be on or the duty cycle is absolutely critical.

Now for a lot of in-crop sprayers where we might be using a medium droplet, I would suggest to people to keep that duty cycle above sixty percent, so start as high as you possibly can don't let the machine slow down too much and the bottom end of 60, maybe fifty percent, but if you change the course droplets they're not going to distribute around as much behind the machine. You want to keep that duty cycle even higher.

So typically i'd aim again start as close to a hundred percent as i can, but in slowing down try not to let it get below about 70-percent with a course and so when you go around obstacles or the end of the field think about how you plan the paddock, with a couple of headlands in, treat it a bit like other sprayers that again is an added factor or duty cycle here which complicates things with pulse width modulation.

Nozzle orifice sizes for PWM systems

The nozzle orifice size selected has a large impact on duty cycle, and therefore the practical speed range for the sprayer at a particular application volume and pressure.

If the operator selects a nozzle that will be operating between duty cycles of 100% to a minimum of 40%, this provides a 2.5 fold speed range, e.g. if the maximum speed was 20 km/h (at 100% duty cycle), then the minimum speed would be 8 km/h (at 40% duty cycle).

To choose an appropriate nozzle orifice size for a particular speed and application volume, a standard nozzle chart that matches the nozzle spacing on the sprayer could be consulted, noting the preferred operating pressure/s for the machine they are operating.

For example:

For a PWM system on 50cm nozzle spacing, spraying at 18 km/h, to deliver 80L/ha.

At 100% duty cycle (continuous flow), this could be achieved with:

025 orifices at 4.5 bar (pressure may be too high for some PWM systems)

03 orifices at 3 bar, or

04 orifices at just below 2 bar (pressure possibly too low for some nozzle types)

From the above example, if an 03 orifice at 3 bar was chosen, then this would only deliver the target application rate at 100% duty cycle, and any time the system slowed down and a lower duty cycle engages then the rate will be decreased. It is better to select an 04 orifice at 3 bar which should result in the PWM system operating around 75% duty cycle on average, but with the flexibility to increase or decrease duty cycle in response to changes in speed.

As a rule of thumb, with PWM systems it is a good idea to choose nozzle orifice sizes that operates at more than 70 percent duty cycle (at the intended operating pressure) to allow for slowing down and for turn compensation.

Duty cycle can be calculated using a standard nozzle chart matching the sprayers nozzle spacing. (In this example, a 50cm nozzle spacing, noting continuous flow on a standard chart is equivalent to 100% duty cycle for PWM).

Using 04 orifice nozzles at 18 km/h and 3.0 bar would deliver 105 L/ha. If a PWM system was set at 80L/ha (same speed, pressure, etc), it would operate at (80/105 x 100) = 76.2% duty cycle.

Carefully consider how 80L/ha is achieved in this example:

Flow rate can only be controlled by having all nozzles on, or by turning off nozzles (often half of the nozzles in a section off at a time, e.g. odd or even nozzles ) for a brief time.

Targeting 80L/ha at 76.2% duty cycle there must be periods of time where all nozzles in a section of the boom are on and on 105L/ha is applied, the remainder of the time either only the odd nozzles or even nozzles will be on in that section of the boom applying 57.5L/ha (105/2).

While the average application rate is 80L/ha, it will rarely be evenly applied, with the variations in application rate becoming more obvious as coarser spray qualities are used.

Uniform application rates can only occur at duty cycles of 50% or 100% (with correct nozzle height).

Duty cycles less than 50% can lead to skips (where all nozzles in a section of the boom off at the same time).

Reference Charts for PWM system duty cycles

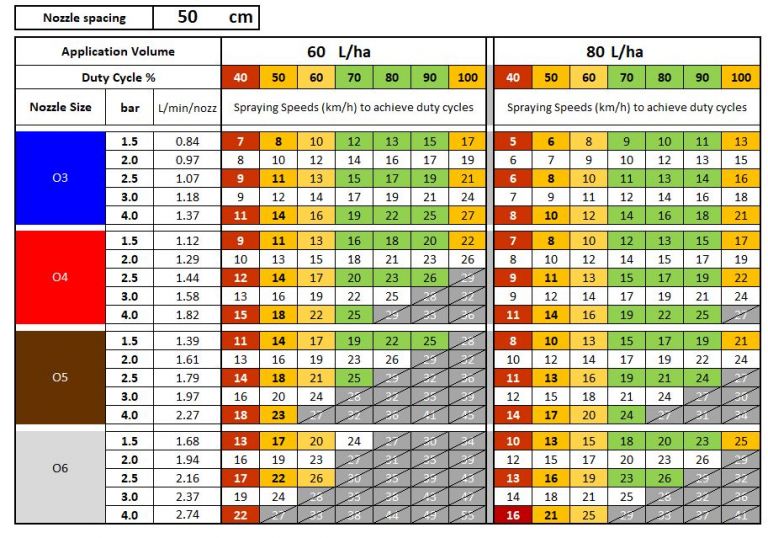

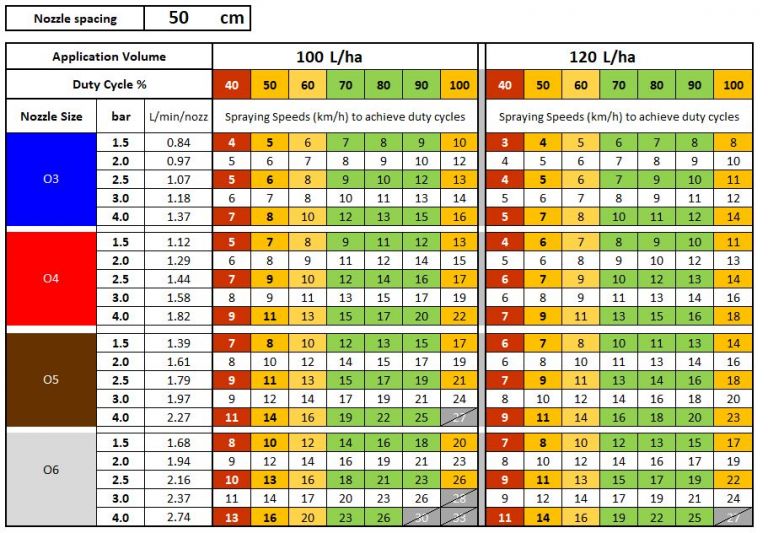

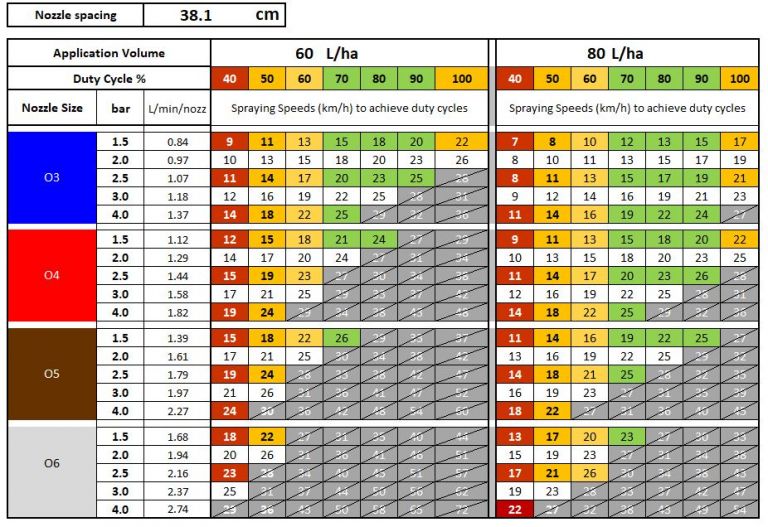

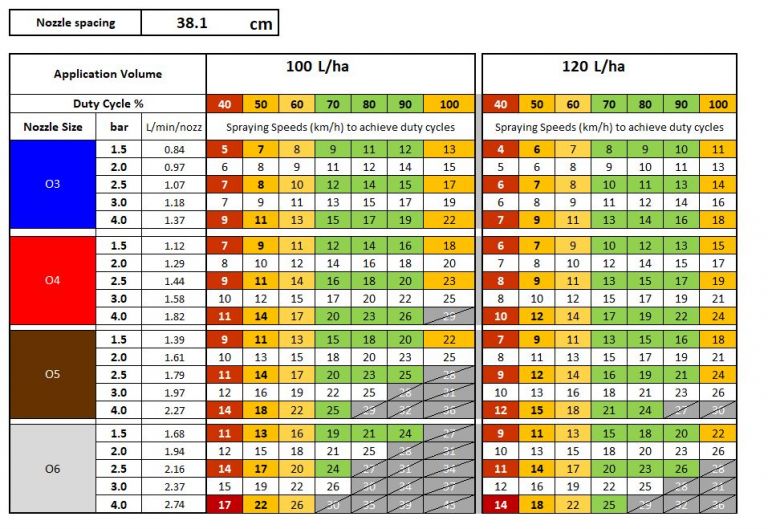

Refer to Tables 1 to 4 as a quick reference for relationship between nozzle choice, spraying speed and duty cycle. These tables compare spraying speeds (km/h) to achieve selected application volumes (L/ha) with various nozzles orifice size and pressure (bar) combinations for a 50cm nozzle spacing and at 38.1cm nozzle spacing.

As a guide to interpreting Tables 1 to 4, use the following guide for speed / duty cycle for each nozzle size and pressure combination:

Avoid spraying at these speeds or slower (the duty cycle is too low)

Minimise time spent spraying at these speeds and duty cycles

Preferred spraying speeds, nozzle sizes, pressures and duty cycles combinations

These speeds exceed what is considered to be best practice and may result in reduced efficacy and increased risk of spray drift

Spraying speeds (km/h) to achieve 60L/ha or 80L/ha with a 50cm nozzle spacing

Spraying speeds (km/h) to achieve 100L/ha or 120L/ha with a 50cm nozzle spacing

Spraying speeds (km/h) to achieve 60L/ha or 80L/ha with a 38.1cm nozzle spacing

Spraying speeds (km/h) to achieve 100L/ha or 120L/ha with a 38.1cm nozzle spacing

Choosing the nozzle size and pressure to maintain the duty cycle at the preferred application volume (L/ha) and speed (km/h) is the first step in nozzle selection, the next step is to select a nozzle type that will produce the required spray quality at the preferred operating pressure.

Spray Quality (droplet size classification)

PWM systems adjust the liquid flow independent of the operating pressure, provided the operator does not try to spray at speeds that would exceed 100% duty cycle for the chosen nozzle and pressure. The ability to select and maintain the preferred operating pressure across a range of travel speeds means that the spray quality will be consistent, which is one of the key advantages of this technology.

When selecting the spray quality for a particular job, the operator must follow the registered product label or approved permit and ensure that the spray quality standards quoted in the nozzle manufacturer’s technical literature complies with standards recognised by the Australian Pesticide and Veterinary Medicines Authority (APVMA).

A number of manufacturers provide reference materials for choosing nozzles for PWM systems, including spray quality charts and app-based tools and ‘Tip Wizards’.

Find out more

Useful websites for PWM nozzle selection include:

For more information refer to the GRDC factsheet Pulse width modulation sprayers: what we have learnt, correct operation and looking ahead.