Spray application manual

4 June 2025

Module 18: Single line and multi-step systems

18.2 Versions of multi-step systems

Published 24 January 2025 | Last updated 20 January 2025

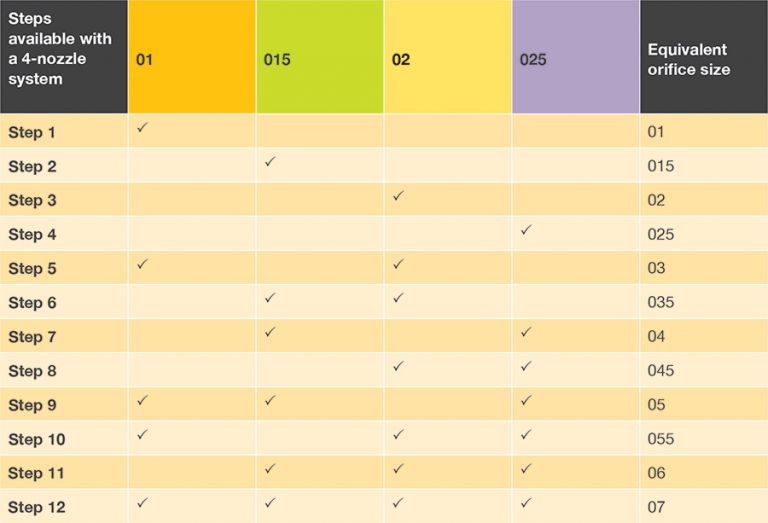

Typically, multi-step nozzle systems are available as a two-nozzle system or a four- nozzle system.

A two-nozzle system may be set up by having two nozzles per outlet across the boom at the standard nozzle spacing (e.g. 0.5 metres) or by having a single nozzle per outlet at a half spacing (e.g. 0.25m). Both set-ups allow for three steps to occur i.e. the first nozzle operating, or the second (larger) nozzle operating, or both nozzles operating together.

A four-nozzle set-up may be plumbed by having four nozzles per outlet at the standard nozzle spacing (e.g. 0.5m), or by having two nozzles per outlet using half the normal nozzle spacing (e.g. 0.25m).

A four-nozzle system generally allows for up to 12 steps to occur as the system transitions between individual nozzles (or combinations of two, three or all four of the nozzles operating at the same time).

Multi-step set-up at 0.25-metre nozzle spacing

A four-nozzle multi-step system set up at 0.5m nozzle spacing

Three tier spray systems.

18 December 2024Three tier spray systems. Another video from GRDC's Spray Application GROWNOTES™ series.

Bill Gordon: The spray system we're looking at here is a three TS or three tier boom. It's one of the multi steps that are available. You can see that this particular one is fitted with air solenoids which allows to boom turn the nozzle on and off on the boom. This is fitted with 01 orifice and 015, so what this boom does it will turn these nozzles on when it gets up to a particular speed it'll switch to these and then when I get to nominated speed they'll all run together.

So the advantage in this system is it gives growers or operates a much greater speed range than say a standard single line. We can run from one to the next and then to both. Now the particular nozzle that's fitted to this one you'll see is a high-pressure air induction it's a little bit longer than the standard ones that most people would see. We're running from 01 orifice then switching to 15 then switching them all together. So with a standard machine this flow rate would be equivalent to running an 025 at 50 centimeters but the benefit is that we run this range of this nozzle than this then both together and that gives us a lot of advantage particularly when we're slowing down it'll also transition from both back to one back to the other, that helps minimize overdosing which is really good in paddocks where you have obstacles or we might have things like contours.

This quick tip where we're alternating novel sizes like this we need to plan to have the overlap or the height of the boom so the overlap is at 50 centimeters, because we have a different flow rate from there to there, we treat it like a 50 centimeter nozzle spacing and have it about 50 centimeters above the top of the stubble, but in this particular setup we get a lot of advantages. The key one is speed range. With these air valves we can also introduce factors like recirculation and boom prime, so there's a lot of advantages to operating a system like this.

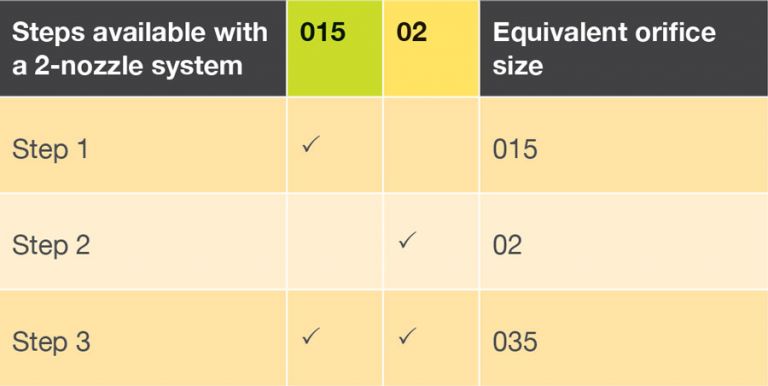

Examples for a two-nozzle – three-step system

When selecting nozzles for a two-nozzle, three-step system, consider the largest nozzle orifice size that the operator would normally use on a standard single line sprayer at their preferred spraying speed and total application volume (L/ha).

If the largest nozzle normally used on a standard single line was a 03 or 04 orifice, then the total flow of the two nozzles for a three-step system should be at least this size, or slightly larger, e.g.:

using an 015 and 02 orifice sizes together produce a combined flow rate equivalent to an 035 orifice size

or using an 015 and 025 orifice sizes together produce a combined flow rate equivalent to a 04 orifice size

By using two nozzles operated in the sequence of the 015, then the 02 (or 025), then both, the operator can gain a greater range of spraying speeds or application volumes (see Table 1).

The nozzles engaged and equivalent flow rate for a three-step system

Planning the transition points for a 2 nozzle, 3 step system

It is critical to consider minimum operating pressure for each of the nozzle types selected, this is usually around 2 bar for low pressure air inductions and around 3 bar for higher pressure air inductions.

In most situations the first nozzle to operate should be the one with the smallest orifice size, then transitioning to the larger orifice size of the two nozzles, then to both.

Care needs to be exercised by the operator when deciding on which nozzles to choose to match their preferred spraying speed and application volume.

Using the example in Table 1, where a 015 and 02 orifice size nozzle are used in combination, the flowrate of the 015 nozzle needs to reach the minimum flowrate of the 02 nozzle at 2 bar (0.65 L/min) before the transition can occur smoothly. To achieve 0.65 L/min the 015 needs to reach a pressure of about 4 bar before the transition should occur (see Table 2).

The transition from a 02 orifice size nozzle to both (015 + 02) operating at the equivalent of an 035 orifice size requires the 02 nozzle to reach 1.13 L/min (0.48L/min + 0.65L/min = 1.13L/min), which can only occur when the 02 nozzle is just above 6 bar, before transitioning to both nozzles operating together at 2 bar (see Table 2). This would exceed the recommended pressure range for many 02 nozzles and may result in a finer spray quality than required.

Required flow rate per nozzle to obtain at least 2 bar pressure

A better alternative may be to operate with an 015 and an 025 nozzle arrangement, which produces a combined flowrate equivalent to a nozzle with a 04 orifice. The transition from 025 to 04 can occur before the 025 nozzle reaches its maximum pressure (see Table 3).

Required flow rate per nozzle to obtain at least 2 bar pressure

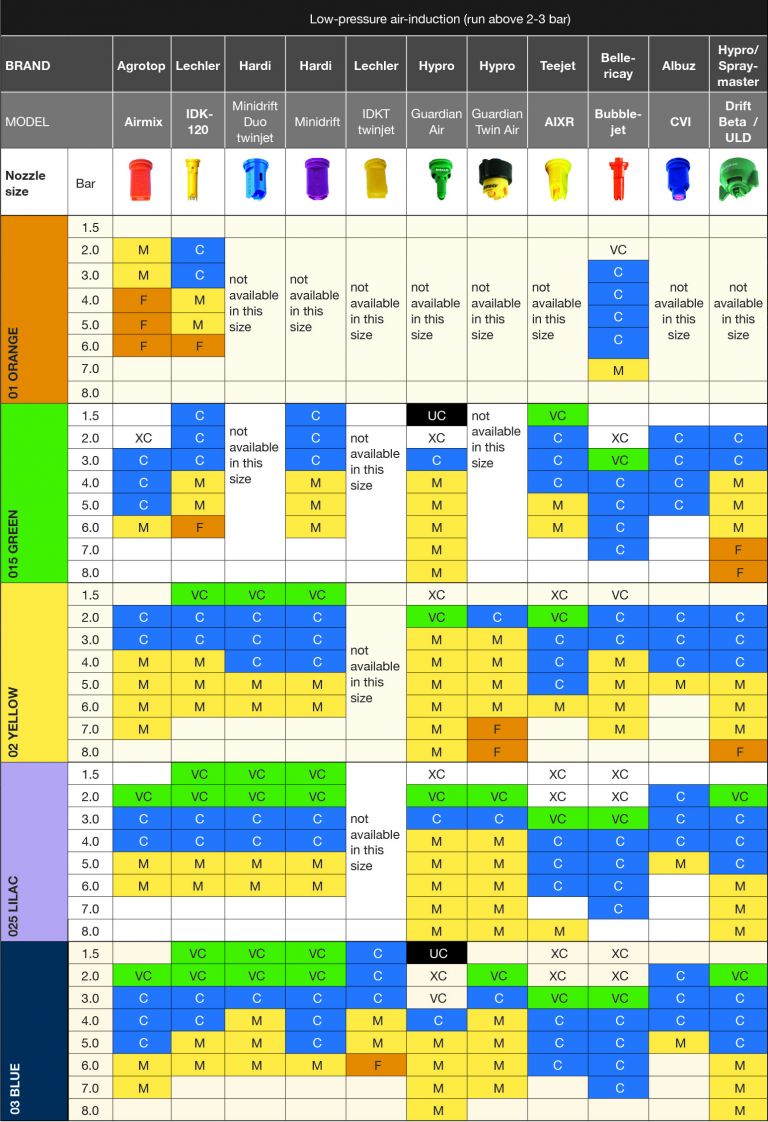

Achieving the desired spray quality with chosen orifice sizes

Once the nozzle orifice sizes have been selected and maximum pressure for transitions between each has been established, a nozzle chart can be consulted to find nozzles that produce the spray quality required (see Table 4).

Example: A tank mix requiring a very coarse (VC) spray quality or larger, applied at 100 litres per hectare using a 2 nozzle, 3 step system fitted with 015 and 025 nozzles at 0.5m nozzle spacing.

Using Table 4 as a selection of air induction nozzles available to this grower, we require a

015 nozzle delivering very coarse or larger up to 6 bar, and

025 nozzle that are very coarse or larger to 6 bar

For the 015 nozzle size, only two nozzles in the chart shown in Table 4 can produce VC or larger up to 6 bar (the Lechler IDKT which is a twin jet, or the TeeJet TTI).

For the 025 nozzle size, an ARAG CFA ultra is rated at VC up to 5 bar, but only the ARAG CFA-T or TeeJet TTI are VC or larger up to 6 bar.

For this example, it would be most practical to select TeeJet TTI nozzles in the 015 and 025 orifice sizes.

A selection of air induction nozzles available between 015 and 025 orifice size

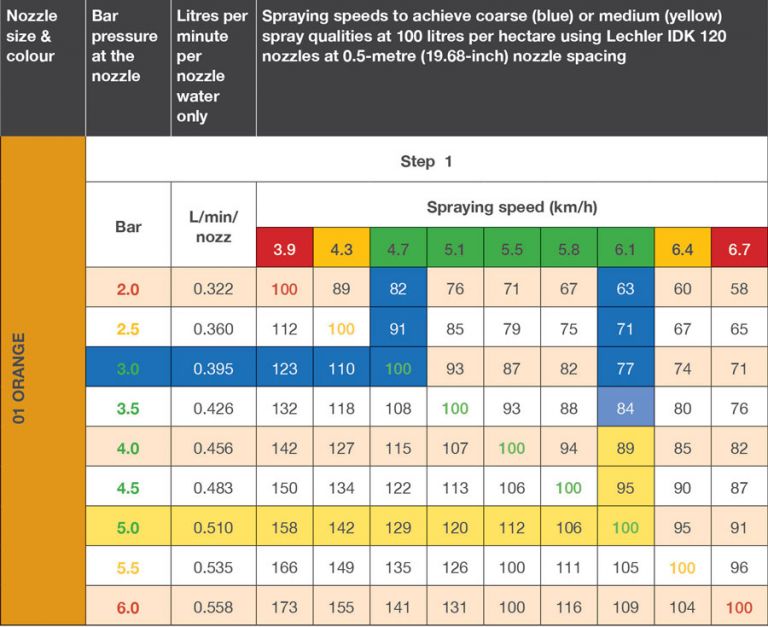

Determining suitable spraying speeds

Having selected nozzle sizes that can operate and transition smoothly, and that produce the required spray quality (or larger), the final step is to select appropriate spraying speeds.

It is useful to identify more than one suitable spraying speed, to allow for changes to be made when conditions or terrain changes.

Table 5 includes the calculated spraying speeds to achieve a Very Coarse spray quality or larger at 100 L/ha, based on a nozzle spacing of 0.5m and the flow rates for the TTI 015, TTI 025 nozzles or a combination of the two, using the formula:

Speed (km/h) = L/min/nozzle x 600 ÷ L/ha ÷ width (m)

Speed (km/h) = L/min/nozzle x 600 ÷ 100 L/ha ÷ 0.5m

Calculated spraying speeds for a 2 nozzle, 3 step system at 0.5m nozzle spacing

Guide to reading Table 5 to identify suitable spraying speeds

Select spraying speeds highlighted in bright green boxes

Avoid spraying at speeds with highlighted by orange boxes

Set the rate controller to transition between the current nozzle and the next nozzle/s listed in each step (on the left of each table) at speeds where a red box with larger white text exists, or at flowrates (litres per minute per nozzle) highlighted by bold red numbers, or at pressures which align with either of these.

Where a minimum hold function exists in the controller (set as a pressure or flowrate for each nozzle), this is suggested as bold black text. For low pressure air induction nozzles, this is usually at a pressure of 2 bar).

Failing to set appropriate transitions can lead to inappropriate spray qualities being produced and/or exceeding suitable operating parameters for the nozzles.

Considerations for planning to operate a two nozzle, three-step systems

Understand why you may need a multi-step system before considering a purchase. Unless you have moderate to large variations in spraying speed in single paddocks, it may not be necessary.

Choose the nozzle orifice sizes based on the largest nozzle size you would normally use, (for a 2-nozzle system aim to select two nozzle sizes that add up to this size or slightly larger).

Work out the transition points between nozzles, based on the minimum pressure required to operate the next nozzle (or combination) in the sequence.

Do not operate any nozzle outside of the manufacturer’s recommended range of operating pressures.

Avoid selecting spraying speeds near a programmed transition point between nozzle orifice sizes. If this is not practical, the operator should consider changing the transition point in the rate controller to avoid transitions between nozzle sizes occurring at speeds close their preferred spraying speed (this may impact spray quality and therefore nozzle choice).

Avoid spraying at speeds where the nozzles are operating at the lower end of the operating pressure, or the spray quality is too coarse for the target and tank mix with the selected nozzle type.

Select nozzles that produce the required spray quality or larger at the programmed range of operating pressures, noting that it is unlikely that a single nozzle type or model can do every spray job.

Understand how to change transition points in the rate controller to achieve different spray qualities and be prepared to do this when required. e.g. where a transition may currently be set to occur at 4 bar for a particular nozzle and orifice size to maintain a coarse spray quality or larger, this may be able to be increased to 6 bar to obtain a medium spray quality or larger.

Consider a range of spraying scenarios, such as combinations of different nozzle types to achieve each of the spraying jobs you are likely to encounter. This may take two complete sets of nozzles to achieve.