Spray application manual

4 June 2025

Module 12: GPS systems

12.7: Section or swath control

Published 24 January 2025 | Last updated 20 January 2025

Section or swath control allows you to automatically turn ‘off’ appropriate boom sections (or even individual nozzles) when the sprayer enters an area where product has already been applied. It automatically turns them back ‘on’ when leaving a pre- applied area. This has numerous benefits including less overlap, reduced wastage, minimised damage from residual chemicals and lower costs.

Trimble’s Field-IQ™ crop-input control system is an example of a system that enables you to control sections or nozzles and shut off sections in waterways and point rows and see where you have been and what you have done with overlap detection.

Ag Leader RightSpot™ also provides application-rate control. The machine’s ‘AutoSwath’ feature reduces over-application and product waste by automatically turning the applicator ‘on’ or ‘off’ based on field boundaries and already-applied areas as it passes over the field. The system reduces input costs and increases application accuracy by minimising skips and overlaps at end rows, fence rows and along waterways.

These are just a couple of examples; all major manufacturers now offer section and nozzle control technology.

There are also options for ‘spot spraying’ using this technology too. By obtaining a file from your local drone operator or satellite imagery solutions company of where weeds were detected, the machine can automatically switch sections or nozzles on and off to only spray weeds. This can lead to a significant chemical saving without the need to purchase expensive weed detection technology on the boom. It also has the advantage of knowing the area of weeds in the field BEFORE you head out to spray.

Find out more

For more information about Field-IQTM, go to: https://ptxtrimble.com/en/products/hardware/flow-application-control/field-iq-crop-input-control-system

For more information about Ag Leader swath- control products, go to: https://www.agleader.com/application/rightspot-agricultural-spray-technology

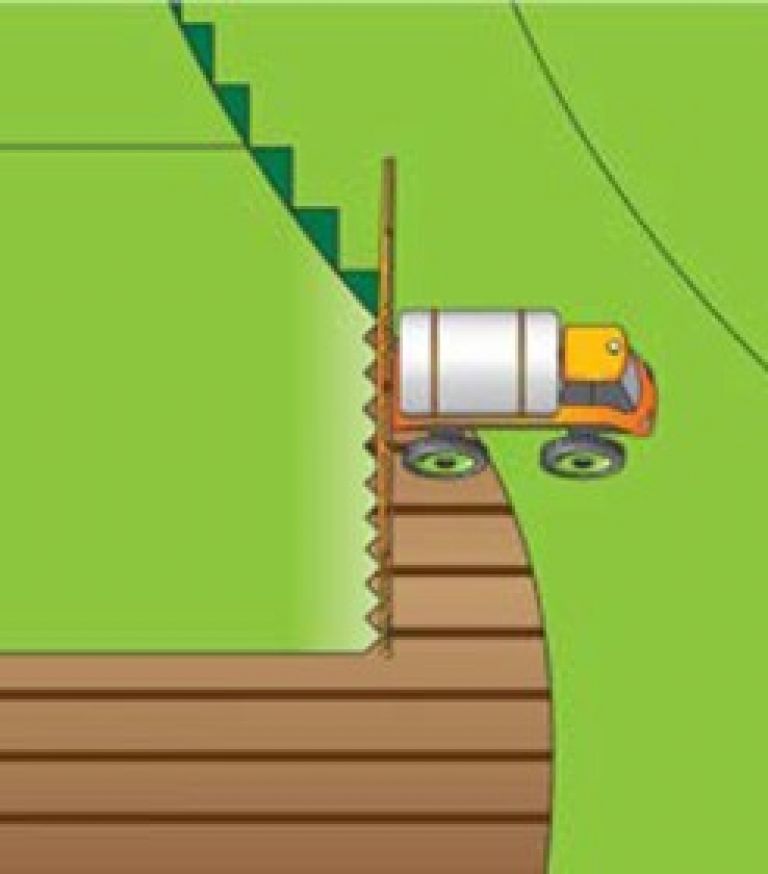

How section control works

Considerations when using swath/section control

Correction signal – the greater the GPS accuracy the less chance there is of misses and overlaps based solely on the repeatability of the system. If you have individual nozzle control and 2km-long runs, for example, then you are unlikely to get the full benefits using a low accuracy correction.

Length and number of boom sections – by increasing the number of boom sections, the more precise you can become with section control and the greater the reduction in overlap.

Nozzle control systems – these allow for precise sprayer application to reduce spray drift. For example, the John Deere ExactApply™ system allows each nozzle to be controlled by its own individual pulsing valve to achieve a more consistent spray pattern.

Find out more

For more information about how pulse width modulation systems can be used for section control, go to: https://grdc.com.au/resources-and-publications/all-publications/factsheets/2023/pulse-width-modulation-sprayers