Spray application manual

8 June 2025

Module 1: Planning for spray application

1.4: Make use of spray plans and mixing plans

Published 24 January 2025 | Last updated 20 January 2025

Knowing the application volumes and spray quality requirements for all the products you plan to use is critical to developing spray plans.

Make lists of products with similar application requirements (volume and spray quality) and make sure you have the nozzles to do each type of job.

Products with similar application requirements may include: knockdown herbicides in fallow, pre-emergent herbicides, liquid fertilisers, contact herbicides (double-knocks), early season broadleaf control, grass-selective sprays in crop, in-crop fungicide and insecticide applications, and pre-harvest desiccation.

Each of these groups of products may require different application volumes and spray qualities, so planning how you need to apply each group makes sense.

Spray plans

Knowing how you want to apply each product (or group of products), in terms of the application volume and spray quality, requires working out which nozzles to have available and at what pressure they should be run.

Completing a spray plan helps to identify the nozzles, controller settings, calibration figures and machine set-up for each group of products, as well as situations where ‘mixtures’ may lead to one or more products being compromised. This will then allow an informed decision to be made if operational efficiency of making the mixture outweighs product performance considerations of a compromised mixture.

A useful spray plan should identify the target flow rate and nozzle operating pressure at your chosen average speed so that they can be checked ‘on the go’ to show that things are running well in the paddock. The spray plan should also identify when to adjust settings, such as the minimum hold (pressure, flow or speed), to ensure nozzles perform correctly or to minimise overdosing.

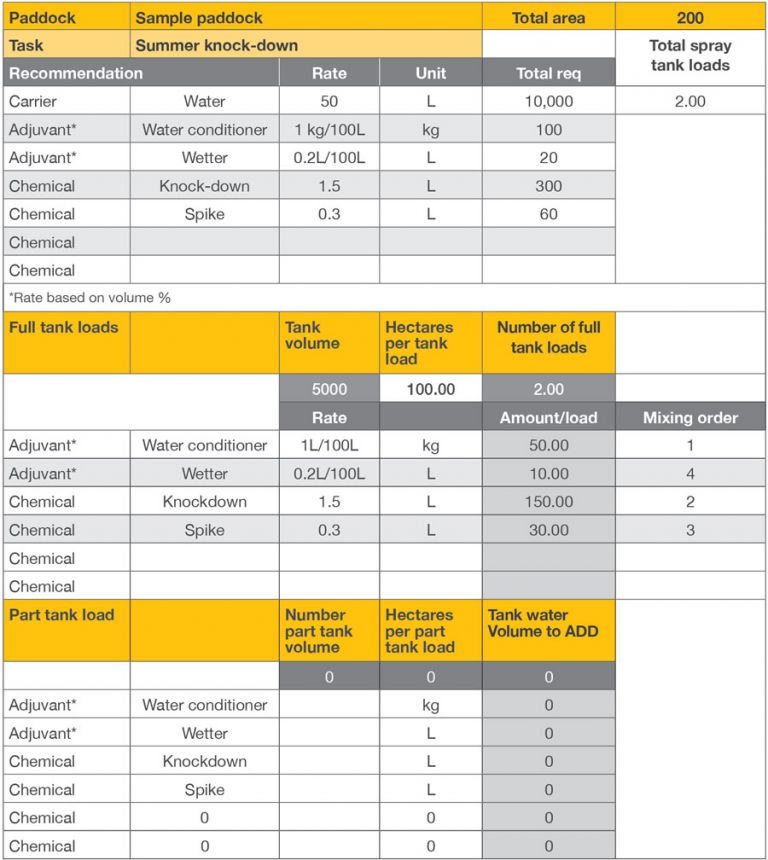

Mixing plans

A mixing plan is a simple way of recording mixing calculations and requirements.

For example, how much of each product will go into the tank, how much of each product (and water volume) is required for the job, and in what order the products should be mixed. Many operators use Excel spreadsheets to do the calculations for them. Using tools such as Excel can help to avoid making easy mistakes.

Spray load calculator

Find out more

For more information go to Module 5: Spray plans.