Spray application manual

7 June 2025

Module 1: Planning for spray application

1.6: Think about how you will spray each paddock (driving technique)

Published 24 January 2025 | Last updated 20 January 2025

It is worth planning your sprays on a paddock-by-paddock basis. Take into account likely conditions and spray run direction.

Consider what challenges each paddock presents in terms of obstacles and ground conditions (wet or dusty) as these will determine a comfortable speed range for that paddock.

If they are not already fitted to your sprayer, think about the value that systems such as auto-swath/auto-section control, height control, boom recirculation/boom prime or multi-step spray could make to improve your spraying efficiency.

Identify downwind sensitive areas and ideally plan to spray when the wind is blowing away from these areas. If spraying must be undertaken in proximity to these areas and the wind is blowing towards them, consider what drift reduction techniques can be employed (i.e. reduce boom height, chose coarser spray quality, slow down), while complying with any buffer zones on the product label.

Managing and maintaining an appropriate speed range

Unless you have a spraying system that can cope with large variations in speed, it may be necessary in some paddocks to increase application volumes to ensure your nozzles are operating effectively when travelling at lower-than-normal speeds.

Ensure that boom height is as low as possible, while maintaining double overlap at the top of the target. Raising boom height, to allow for faster travel speed, is one of the leading causes of spray drift.

Headlands

One way to reduce the speed range during spraying operations is to include sufficiently large headlands. Wide headlands can help to avoid operating at lower speeds (reduced pressure) at the ends of runs and minimises operating with the sprays on during turns. A practical headland matches the seeder width so that crop direction is the same as the spray runs.

Having auto-section control and an accurate GPS can make this job much easier. Systems that increase your operational speed range, such as multi-step booms or pulse width modulation can reduce the width that headlands may need to be.

Obstacles and turns

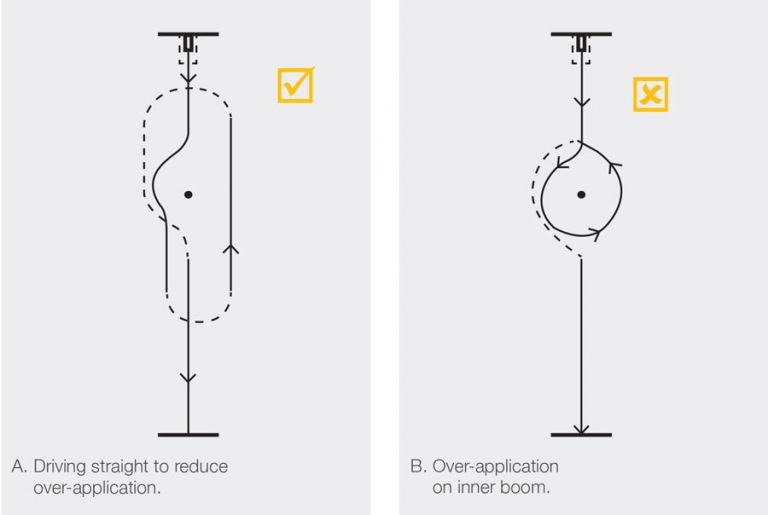

While many spray systems can help to manage variations in straight-line speed, very few can fully compensate for the changes in application rate that occur across the boom if operating with the spray on during a sharp turn.

Planning how you are going to spray around obstacles is important for ensuring good control because of the potential consequences of under and over-application. This is a situation where auto-swath/auto-section control is very useful. However, even with auto-section control, gentle turns are critical.

Obstacle spraying

Corners

It is a good idea to square up the ends of the paddock to minimise operating with the sprays on during turns. It is also important to consider how to deal with corners.

Generally, the best approach is to back into corners with a rear-mounted boom (or drive into corners with a front-mounted boom), provided your spraying system can operate effectively at the initially low take-off speeds. Auto-section control can also help to prevent overdosing when backing into corners.

Paddock corners

Direction of travel

It is a good idea to mix up your direction of travel. Each time you spray a paddock, start at the opposite end to where you started last time. This helps to overcome some of the effects of shadowing behind standing stubble, particularly if you are doing a double knock with ‘contact’ herbicides.

Alternating wheel tracks

In situations where dust is an issue it can be a good idea to alternate the wheel tracks you use for spraying products in fallow situations. Shifting across a planter width each time you spray can help reduce some of the problems associated with poorer weed control adjacent to the wheels and in the centre of the machine.

Leaving unsprayed buffers

Sometimes you may have to operate close to sensitive crops or other areas where you don’t want to risk the product moving off-target. If it is not possible to spray these areas first when conditions are favourable, it can be useful to leave unsprayed areas within a paddock.

Unsprayed areas can be left if you are expecting a change in wind direction. This allows those areas to be sprayed later, possibly with a different set-up.