Spray application manual

4 June 2025

Module 10: Weather monitoring for spraying operations

10.2 Important weather parameters for spray operations

Published 24 January 2025 | Last updated 20 January 2025

Weather influences the outcome of any spray job, in terms of both efficacy and spray- drift risk. Legal requirements, both on the label and in state or territory legislation, also require applicators to record weather parameters during application.

Label requirements

Many product labels (depending on when they were approved) include a requirement for the spray operator to measure, record and comply with directions surrounding wind speed, wind direction, temperature and humidity during the application at the actual application site.

Wind speed and direction are particularly important in determining the risks associated with spray drift, but will also influence how uniform the spray coverage will be.

Temperature and humidity are important for assessing potential impacts on efficacy, as they can affect both the condition of the target plants and the fate of the droplets after they are released by the sprayer.

To comply with the label requirement, it is best to record conditions at the start of spraying and at the end of each tank. Recording the weather conditions at regular intervals can help to identify if, or when, conditions may have changed, which can be important to meet record-keeping requirements in individual states.

Wind speed and wind direction

Wind speed and wind direction are probably the most important factors to consider when making the decision about when to spray and when to stop.

Spraying when the wind is blowing away from sensitive areas is one of the most important strategies for reducing the potential for damage from off-target movement of spray droplets. Ensuring that there is enough air movement to dilute airborne droplets and minimise the risk that an inversion may be present is also key.

Accessing reliable weather forecast information is critical to planning the spraying operation. It is important to pay close attention to expected changes in wind direction and wind speed, and when these changes are likely to occur throughout the day.

Monitoring wind speed and using as many visual clues as possible while you are spraying helps to ensure that wind direction hasn’t changed as you move around the farm, or at different times of the day.

Wind direction

Wind direction at a specific location is not difficult to identify at a particular point in time. However, variations in topography may influence local wind direction at different places around the farm. In some locations wind direction can be different from one end of a paddock to the other. This is why it is essential to measure and record the weather conditions at the site of application.

When recording wind direction, be aware that there are variations between magnetic north, true north and grid north. It is important to be aware of which version of north your measurement is based on.

True north (the axis of the Earth’s rotation) and grid north (the top of a map) are generally within degrees of each other. Often the variation between true north and grid north will be indicated on a detailed map.

However, magnetic north (where a magnetic compass points) can vary by several degrees from grid north (‘north’ on a map) depending on your location, as the compass will be influenced by the Earth’s magnetic fields. The difference between the two will also be affected by the date when the map was produced.

When setting up a weather station, or taking wind direction measurements using a magnetic-compass, be aware of the difference between magnetic north and grid north. Always record which ‘north’ has been used.

If using a GPS-based system to indicate direction, this should take the variations into account.

Find out more

For a simple explanation of the different versions of ‘north’ go to: www.maptools. com/product/ NorthRefSheet

For tools to adjust between magnetic north and true north or grid north go to: www.ga.gov.au/ oracle/geomag/ agrfform.jsp

Measuring wind speed

Wind speed is often difficult to estimate, particularly when it is gusting. Record- keeping requirements on product labels state that wind speed must be measured at the site of application.

For record-keeping purposes, record the average wind speed at two metres above the ground at the application site, along with the time it was recorded. The point where you measure the wind speed should be representative of the application area and should be free of obstructions that may impact the measurement.

From an application point of view, variations in wind speed are also important, as these may affect the uniformity of the spray deposits, particularly when using medium or fine spray qualities.

As a rule of thumb the maximum wind speed (gusts) should not be more than about one-third of the average wind speed above the average wind speed.

For example, if the average wind speed at the site of application is 15 kilometres per hour, then you would not want gusts to be above 20km/h (15km/h + 5km/h).

Using a hand-held meter at the application site

If the operator is relying on measurements from a permanent weather station, it should be located within line of site of the sprayed paddock (generally within 2km), and not more than 5km from the site of application.

Bureau of Meteorology records of wind speed and direction

There are a couple of things to keep in mind when relying on Bureau of Meteorology (BoM) forecasts or records for wind speed and direction. The first is the size of the forecast area, which may not fully represent wind speed and direction at the site of application.

The second consideration is the height at which the BoM measures wind speed. Official BoM records of wind speed are generally taken at 10 metres above the ground to avoid surface turbulence.

Wind speed normally increases with height, so measurements of wind speed at 10m above the ground will be greater than what would be experienced at 2m above the ground at the site of application. Other factors such as ground cover and stubble will increase the friction at the surface, further slowing the wind speed close to the surface.

Wind speeds at 2m above the ground in a paddock with good ground cover or crop may be less than 50 per cent of a measurement taken at a height of 10m.

Tip

All downwind buffer distances (no-spray zones) included on product labels are based on a wind speed measured two metres above the ground.

Visual clues of wind speed and direction.

Visual observations of what is happening outside the cab are very important while operating the sprayer. While these observations will not meet your legal requirements to measure and record the conditions, they will provide an indication that the weather parameters are either fairly constant or changing, which indicates that it is time to re-evaluate conditions.

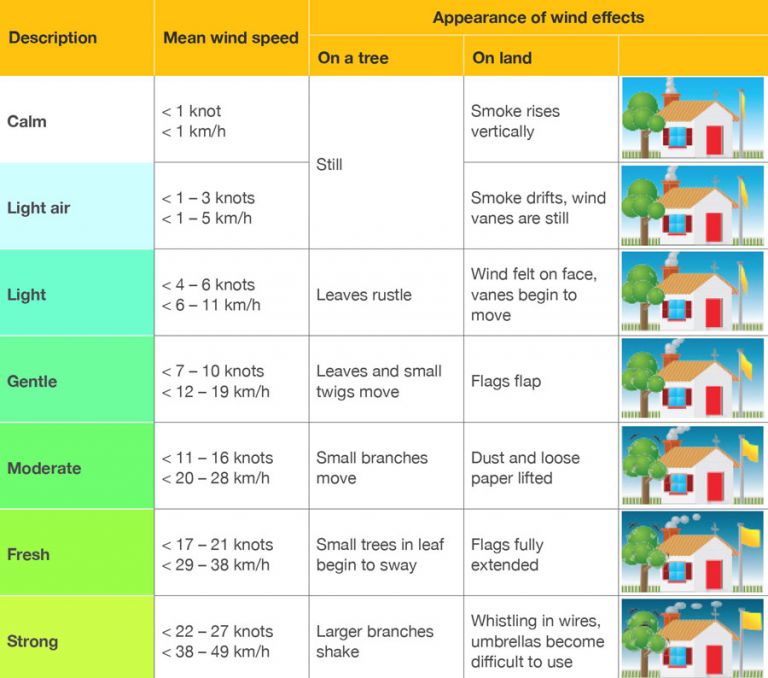

The Beaufort wind scale is a useful guide for estimating wind speed, while windsocks and other visual aids are useful for assessing wind direction.

DRT - Cloud observation

15 January 2025Observing cloud formations plays a part in spray drift reduction. Another video from GRDC's Spray Application GROWNOTES™ series.

This video appears in modules 4 and 10.

Bill Gordon: One of the things we can utilise when we're spraying is the visual clues and things happening around us, and certainly clouds are a great indicator of what's going on. When we see fluffy clouds—the cumulus ones that start to form in the morning—that means the inversion is generally broken up to about that level. Later in the day, they're also a good indicator of the onset of an afternoon inversion. So when we look at those clouds and they start flattening out on the ends, particularly in the distance, I'd expect we've probably only got another 20 or 30 minutes before the wind speed tends to drop off.

When the sun gets below about 20 degrees, the clouds are flattening out, and the wind speed drops, it becomes very dangerous for spraying because we can't predict what's happening. So, using visual clues as well as monitoring the weather is very important for spraying operations.

The Beaufort Wind Scale

Windsocks and other visual aids

Windsocks are a useful way of assessing wind direction, and may also be useful for estimating wind speed. Some windsocks available are ‘calibrated’, so that the angle of the sock indicates wind speed. While these devices are very useful for visual observations, they are not a substitute for physical measurements of wind speed using an appropriate instrument.

The image below shows a windsock ‘calibrated’ for measurements between 3.2km/h and 19.2km/h. As an alternative visual indicator, surveyor’s tape or ribbon can be attached to an aerial or a fibreglass rod mounted on the sprayer.

Find out more

For further information see: www.windsocksaustralia.com/au/shop/

Windsocks mounted on the sprayer

Smoke and dust

Any visual clue that moves with the wind, such as smoke or dust, is valuable for determining how the air is moving and mixing.

It is not always practical to have a fire burning near the application site, so many operators have fitted ‘smokers’ to their sprayers, similar to those used on agricultural aircraft.

Releasing smoke in the paddock allows the operator to assess air movement from the cab.

Generally, this can be set up by using a small tank and low-capacity 12-volt electric pump to inject a paraffinic-oil-based product (such as ‘summer spray oil’) into the engine exhaust after the header pipe. Windscreen-washer kits from automotive wreckers are ideal for this purpose. Usually the systems are plumbed using fuel-grade lines and fittings.

Farm equipment

Tips

Smoke will initially rise, but it should then move with the wind. If it continues to rise conditions may be too unstable, due to excessive surface temperatures.

Ideally smoke will spread out and appear to dilute or disappear as mit moves downwind, with some smoke returning towards the surface.

If puffs of smoke remain intact and move slowly, the air is not mixing and moving enough to bring airborne droplets back to the surface and it may be too risky to spray.

Releasing smoke while driving with the wind direction (e.g. wind coming from directly behind the sprayer) allows the operator to judge the wind speed relative to the speed of the sprayer at the time.