Spray application manual

8 June 2025

Module 7: Mixing and decontamination

7.2 Decontamination Agents

Published 24 January 2025 | Last updated 20 January 2025

The highest risk of crop damage usually comes from herbicide residues remaining in the sprayer (blindspots, inside tank, ceiling and hose) or mixing equipment, which are subsequently released in the next spray load.

However, all residues pose the risk of interactions with future tank mixes if they are not correctly removed from the spraying system and mixing equipment. Most labels provide information on the cleaning agents required to remove product residues, but applicators need to be aware that the cleaning process is just as important as the cleaning agent used.

Always check the expiry date of cleaning agents and the amounts of each product that are required to be added to the volume of water held by the tank or mixing equipment. Never mix chlorine (bleach) and ammonia as a reaction can occur that results in the emission of a toxic gas.

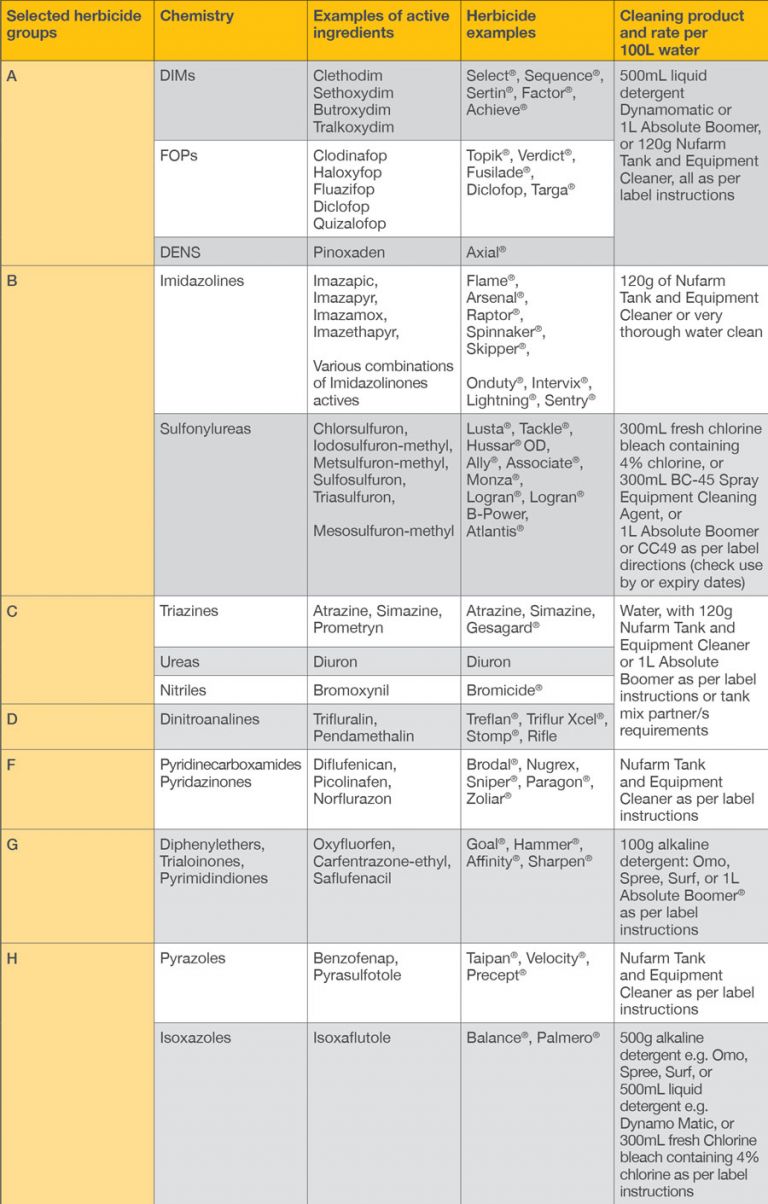

A summary of label advice for the most common broadacre herbicides.

Water – Thorough water clean, typically as a triple rinse. Where other products have been tank mixed then follow advice for the partner product.

All Clear DS (and similar products based on a combination of benzenesulfonic acid and tetrasodium bisphosphonate) – Marketed as a boom cleaner and chelating agent.

Boom cleaner – Several commercial boom cleaners are commercially available. Typically these are some combination of sodium tripolyphosphate; sodium hydroxide; sodium carbonate and/or chlorine. Most product labels do not recommend a specific brand or formulation. Follow individual boom cleaner labels for use rates.

Alkali detergent – e.g. OMO, Surf. Typically used at 500mL (or g) per 100L water

Ammonia – 1L of 3% household ammonia per 100L water

Chlorine bleach – 300mL of 4% chlorine solution per 100L