Spray application manual

7 June 2025

Module 7: Mixing and decontamination

7.7 Importance of water quality for mixing operations

Published 24 January 2025 | Last updated 20 January 2025

Water quality can also play a role in the ability of products to fully dissolve, disperse or interact with other products. When using water from a source where the quality is unknown, it is always important to determine the water quality before mixing many products.

Find out more

Information on water quality requirements and test procedures can be found in the GRDC Fact sheets Mixing requirements for spraying operations and ‘Spray water quality’

Water quality test strips

In-field tests of basic water-quality parameters such as pH, total hardness and salinity can be done with test strips available from suppliers of swimming-pool products or major hardware stores.

However, other parameters, such as bicarbonate levels, need to be determined by a suitable laboratory test.

Further information on water quality requirements and test procedures can be found in the GRDC Fact Sheets ‘Mixing requirements for spraying operations’ and ‘Spray water quality’.

Crystalline ammonium sulfate

Crystalline Ammonium sulfate (CAMS) is one of the most commonly used tank-mix additives in Australia and should receive a special mention. Only use CAMS products that are registered as spray adjuvants, and always follow the label instructions.

Tip

Label rates of liquid or crystalline AMS typically provide a general use rate that will cover most water hardness situations. If a water test is available, you can calculate the actual amount of CAMS from the following formula

Kg CAMS / 100L water = (0.001 x Ca (ppm)) + (0.0006 x Na) + (0.0002 x K) + (0.0017 x Mg) + (0.005 x Fe)

As a water conditioner, CAMS should be added first in the mixing process. While adding salt into water sounds simple enough, there are some important steps to take to ensure that the tank mix is stable.

Tip

Time and adequate water volume is required for successful mixing of ammonium sulphate.

Potential issues with using CAMS

Water temperature

Crystalline ammonium sulfate needs to absorb energy to dissolve. The only way it can obtain the energy required is to remove heat from the water (an endothermic reaction), effectively cooling the water down. The temperature drop that occurs will depend on the amount of CAMS added to the water.

When starting to mix CAMS it is important to start with a high water volume in the tank, about 60 per cent of the total tank mix volume. If the total application volume per hectare is only 50L/ha or less, it is a good idea to increase the initial water volume for mixing to 80 per cent of the total tank mix volume. This is particularly important during winter when the water is already cold as the cooling effect of adding CAMS can make the mixing of products to follow more difficult. As a rule of thumb, the warmer the water is, the easier the mixing becomes.

Time to dissolve

It is essential that all the CAMS is fully dissolved before other products are introduced into the tank mix, especially when using 2,4-D. Depending upon the quality of the CAMS, water temperature, agitation and concentration of CAMS, it is common for it to take up to 10 minutes to fully dissolve. Often it is not practical to stop the agitation to see if all the CAMS has dissolved in a dark tank filled with an opaque solution water. The best option is to allow 10 minutes after adding the last bag of CAMS before introducing the next product. If water quality is poor it may be a good option to have another tank the same size as the main spray tank to treat all the water to allow time for the interactions to occur before product is added.

Product quality.

The quality of CAMS batches, even within the same brand, can vary considerably. It is best for the operator to assume that the quality of the batch may be low. Filters should be checked regularly and the mixing time should always be budgeted at 10 minutes per tank.

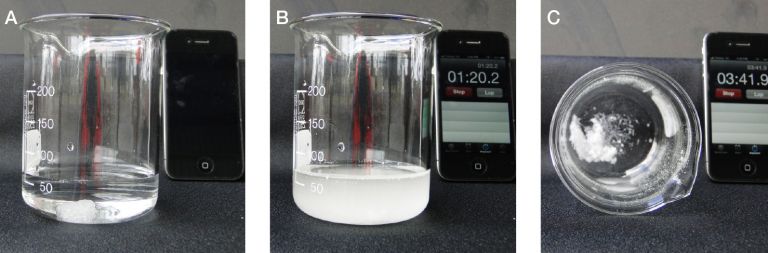

The impact of adding 2,4-D before CAMS has fully dissolved

Potential solutions to issues with CAMS

When suitable conditions for spraying exist, time is at a premium. Many applicators may not want to wait an extra 10 minutes or more to allow CAMS to fully dissolve. There are ways to avoid the additional time:

Use liquid ammonium sulphate, which is already pre-dissolved and has the impurities filtered out. It is a ready-to-go, very user-friendly form of ammonium sulphate that can easily be used through chemical transfer systems. The use rate is 2L/100L rather than 0.8 to 1 kilogram (kg)/100L. The higher transport weight and the pre-mix service can result in roughly a doubling of the price of CAMS, but it may be a cost-effective solution considering the time saved.

Use a pre-mix vat or tank to make your own liquid CAMS. CAMS can be pre-mixed and pre-filtered before the tank mix is prepared. CAMS can be pre-dissolved at a rate of 500 grams per litre of clean water, even at lower water

temperatures. If CAMS is dissolved at this rate, the operator can use 2L of the pre-dissolved product in place of 1kg of the original crystalline form. There are a number of pre-mix vats on the market with very high agitation and excellent flow performance that can help speed up this process. When pre-mixing CAMS it is useful to ensure an in-line filter with a coarse screen is in place to remove any larger particles and impurities.

Pre-treat the water required for the following day(s) by adding the required volume of CAMS into a batch mixer under agitation. Once the CAMS is fully dissolved, the ‘batch’ can be moved to storage tank and the process repeated until sufficient water has been pre-treated for use the following day.

Tip

The solubility of a common crystalline ammonium sulfate product registered as a spray adjuvant is stated on the safety data sheet as 754g/L at 20°C in water (of good quality). However, to fully dissolve this amount would take quite a long time.