Spray application manual

8 June 2025

Module 22: Integration of the sprayer with other farm equipment

22.4 Row width and tyre centres

Published 24 January 2025 | Last updated 20 January 2025

Row width and tyre centres - striking the right balance on the seeding equipment to improve the accuracy of spraying operations

The selection of appropriate row spacings for various crops should be driven by agronomic factors, such as yield potential, harvestability, crop competition against weeds and disease management, appropriate for your location and soil type.

Once appropriate row widths have been established, the operator should plan the seeder’s width to work with the width of the cutter bar on the harvester (excluding gatherers). The width of the seeding equipment could generally fit in with the cutter bar width in a 1:1 ratio, a 2:1 ratio, or a 3:1 ratio or more in some circumstances.

The number of rows established on the seeding equipment should take into account the spacing between the tyre centres. It is important to consider whether an even number of rows or an odd number of rows on the seeding equipment will work best for your situation. The choice largely depends on whether the operator is happy to drive over planted rows or would prefer to have the wheel tracks in the inter-row space as much as possible (the alternative is to adjust the crop row width around the tyres).

A 3-metre wheel extension on a John Deere tractor

Full front-axle extension on a John Deere tractor

Wheel extensions on a Case tractor

Choosing either an even number of planted rows or an uneven number of planted rows

To minimise crop damage, generally using an even number of planted rows will often work better than using an odd number of planted rows.

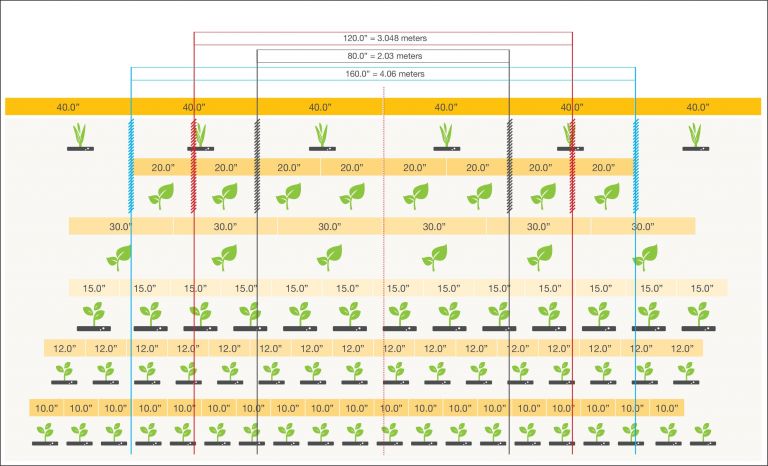

For example, Figure 4 shows three different spacings for the wheel centres and the position of the crop row for a range of possible row widths, based on an even number of rows planted.

Position of the wheels and traffic in relation to row spacing for an even number of planted rows (based on imperial row spacings).

Using an even number of planted rows (broadacre set-up)

From Figure 4 it can be seen that if the machinery was set up with a 120-inch wheel centre (red), and an even number of rows was planted (a broadacre set-up, with the same number of rows either side of the unplanted centre line of the equipment), this would work for most situations, except for a 40-inch row spacing (as the wheels will travel directly over the planted row).

However, many of the other row spacings illustrated could work well for an even number of planted rows and 120-inch wheel centres, including 20-inch and 10-inch rows. The 30-inch, 15-inch and 12-inch rows would work to a lesser extent, but some compaction and possible crop damage would occur.

For a 40-inch row spacing, either 80-inch or 160-inch wheel centres would be preferable, which would also work well for 20-inch rows and for 10-inch rows, but would be less suitable for 30-inch, 15-inch and 12-inch row spacings.

Using an uneven number of planted rows (row crop set-up)

A row crop set-up has an uneven number of planted rows, where a row is planted directly in the centre of the equipment, with the same number of rows planted on either side of the centre row (refer to Figure 5 for an example).

There are only a limited number of situations where an uneven number of rows should be the preferred set-up. Figure 5 illustrates that a 120-inch wheel centre may work well for an uneven number of 40-inch row spacings, but does not work well for any of the other crop row spacings shown in this example.

Position of the wheels and traffic in relation to row spacing for an uneven number of planted rows (based on imperial spacings).

Examples of how various tyre centres, row spacings and number of rows may work together

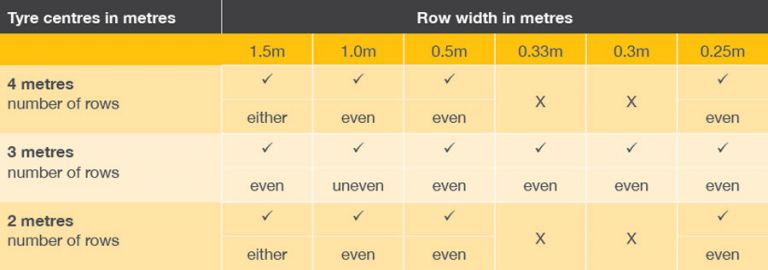

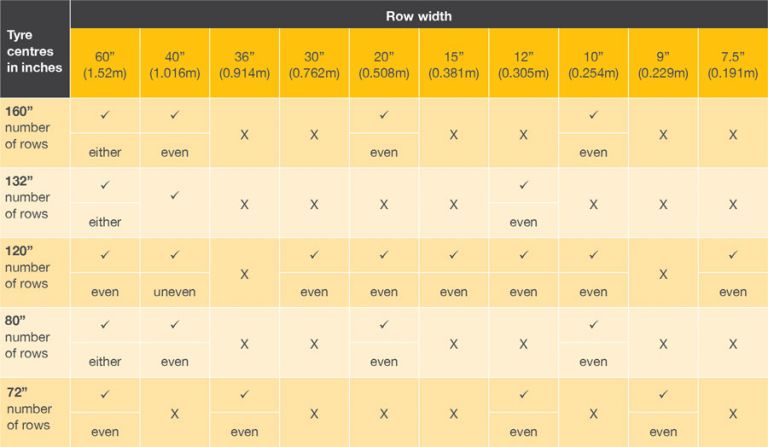

Tables 1 and 2 provide examples of how tyre centres and row spacings may work with either an even number of rows or an uneven number of rows. Where a tick (ü) is present this combination will work, where a cross is indicates (X) this combination will not work.

The words below the tick (ü) or cross (x) indicate whether an even number of rows or an uneven number of rows is required, or where either an even or uneven number of rows will work.

Examples of how imperial tyre centres and row widths may work together with even or uneven row numbers.

Examples of how metric tyre centres and row widths may work together with even or uneven row numbers.