Spray application manual

8 June 2025

Module 15: Weight, balance and tyres

15.2 Terminology for tyre specifications

Published 24 January 2025 | Last updated 20 January 2025

- Tyre acronyms, symbols and terms used in this module

- Tyre categories

- The load index and corresponding weights the tyre can carry

- Load bonuses and self-propelled sprayers

- Speed symbols used on sprayer tyres

- Tread patterns for sprayer tyres

- Rolling circumference index

- Rim size and type

- Tyre beading pressure

- Toe in toe out

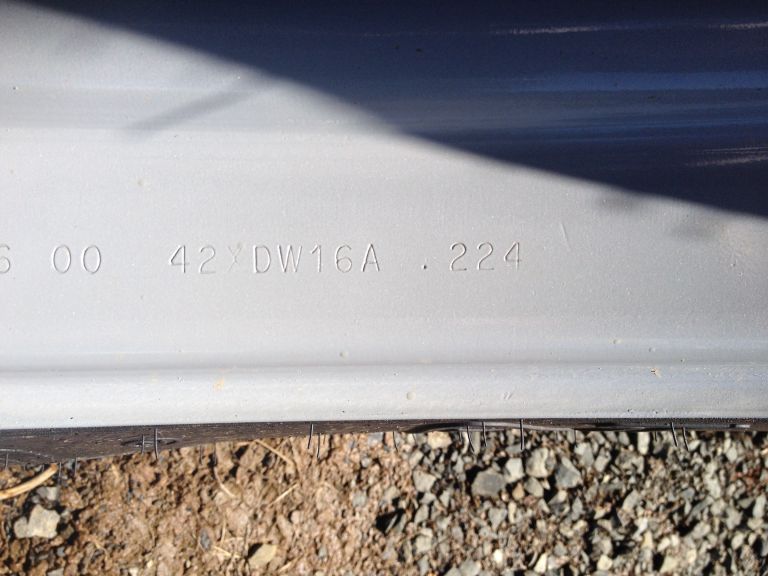

Every tyre has a lot of information stamped on the side wall. The information stamped on the rim (generally stamped near the valve stem, sometimes hard to find because of paint) is very important also, as tyre manufacturers technical specifications mention preferred or acceptable rims for the chosen tyre. If the tyre is not matched to the rim (Refer to photo 2.7) the tyre bead may be compromised.

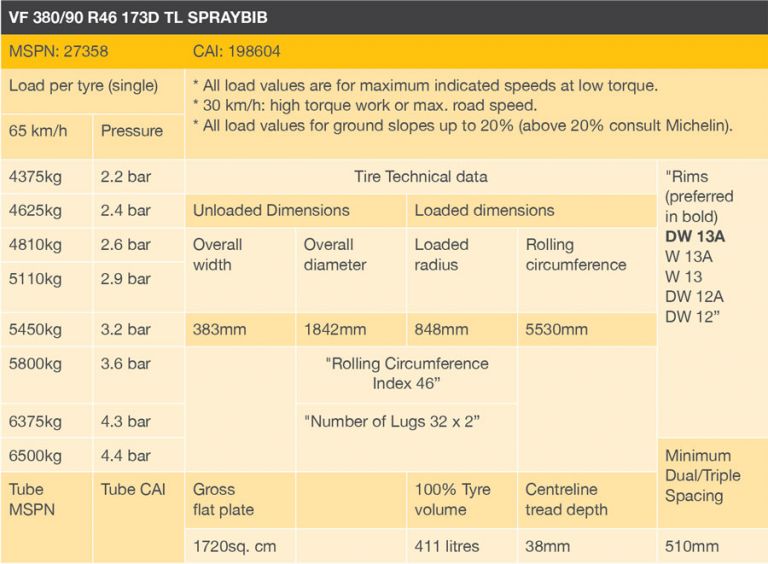

This information is also available in the manufacturer’s technical literature. For example, the information included in Table 1 is supplied by Michelin for the sprayer tyre SprayBib, VF380/90 R46, R-1, 173D.

Tyre information importance for purchase

9 January 2025Tyre information & its importance when considering a purchase. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: The next part of this process is to understand all the information on the tyre and when you're buying or purchasing a tyre the information you need to look for. Obviously brand that's pretty common sense. This one's very important that's the model of the tyre. Obviously we're all familiar with this. The 540 is the width of the tread, 80 is 80 percent of the 540 is the depth of the tyre. R - it's a radial. 38 inch is the rim, and this one just happens to be an industrial tyre and this is the old imperial figures which now is the new metric 540, 80R 38, but that's only about twenty-five percent of a tyre. 75-percent of the tyre is this information - the load rating and speed. The 172 is the load rating and the A8 is the speed symbol. That equals a certain amount of kgs and that's at 40 kilometers an hour.

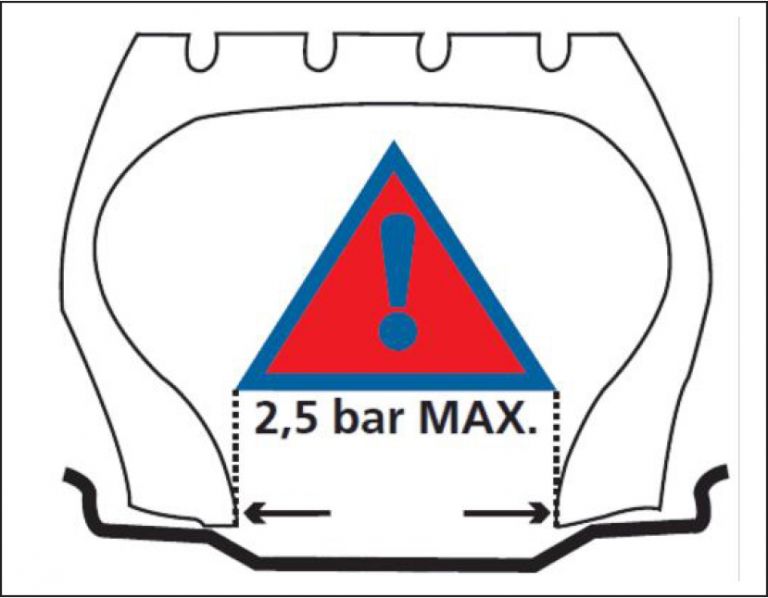

If you want to go faster it's a lower load capacity and a bit higher speed the d stands for 50 kilometers per hour. I've graffitied the tyre but this information should be on there also, it's very very important. RCI stands for rolling circumference index 48, and that 48 is a group number to tell you the rolling circumference of the tyre. Very important this 2.5, that's the beading pressure, has nothing to do with the operating pressure. So it's saying don't go over 2.5 bar when you're beading the tire. Very important to find out what the maximum inflation pressure is, a lot of tyres will have maximum pressure at maximum kilograms the tyre can carry. They're only maximums, you don't need to operate the tyre there and we don't like to operate tyres at that pressure, we like to operate down to about 75% of the maximum. It's not on this tyre, this industrial tyre, but has a tread pattern very similar to an R3. What that means, is we've got seventy percent contact and thirty percent void, where the other R1 tyres will have seventy percent void and thirty percent contact. Why we're going for this type of tyre is that it cuts up the paddock a lot less.

To summarize all of what we've learnt, we've learned about all the numbers on the tyres, we also need the weight information and these numbers when we go into our tyre dealer, including the rim number. When you have a look at the tyre manufacturers catalog to see what tyre is matched up to what rim, that's very important. The reason we're doing all this is that we've got a lot of weight about us, a big tank capacity and the big issue is we're damaging our paddocks because we aren't getting this right. We're having to put far too much pressure in these tyres. We need to get that tyre pressure down to about 20 to 25 psi, but also tyres and the tyre pressure has a very big impact on the stability of the boom, and obviously the comfort of the operator, and also your auto steer, if you don't get all this right your auto steer could not work properly.

Tyre acronyms, symbols and terms used in this module

10LT - low torque, maximum speed 10km/h

10HT - high torque, maximum speed 10km/h

B - high rim flange

CTI - controlled tyre inflation

CVT - constantly variable transmissions

DTR - drive train ratio

DW - drop well, drop well shaped rim

FR - free rolling

FWA - front-wheel assist

HP - horsepower

IAR - inter axle ratio

IF - increased flexion

IVT - infinitely variable transmissions

L - low rim flange

lbs - pounds

LSI - load speed index

MFWD - mechanical front-wheel drive

psi - pounds per square inch

OD - overall diameter

PTO - power take-off

PR - ply rating

RC - rolling circumference

RCF - rolling circumference front

RCI - rolling circumference index

RCR - rolling circumference rear

SH - section height

SLR - static load radius

SLW - section loaded width

SRI - speed radius index

SW - section width

VF - very high flexion

W - well, wide drop centre, single well shaped rim

Michelin VF 380 90 R46 specifications sheet

Michelin: the tyre manufacturer’s name

SprayBib: the tyre model (in this instance also describes the tread pattern)

VF: the tyre category, e.g. very flexion (VF). There are several tyre categories discussed after this overview.

380: tyre tread width in millimetres (mm)

90: is the ratio/percentage of section height from the bead to the top of the tread (e.g. 90% of 380mm = 342mm). This ratio will change as the tyre wears, which will have an effect on the rolling circumference, which is particularly important for the lead or lag for four-wheel drive tractors.

R: ‘radial’

46: indicates the rim size in inches that the tyre must be fitted to

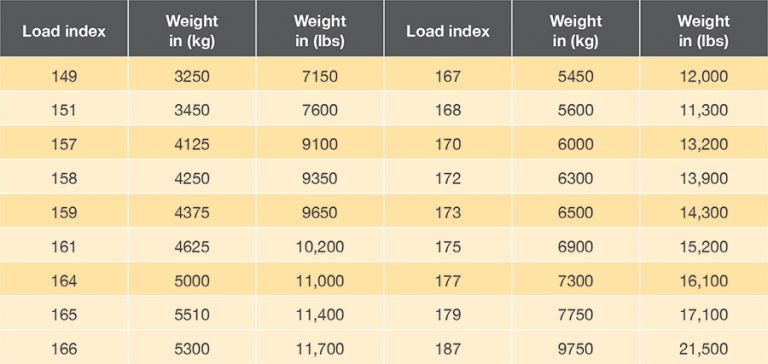

173: the load index, 173 = 6500 kilograms. This figure is the metric version of ply, star rating that can be seen on some tyres.

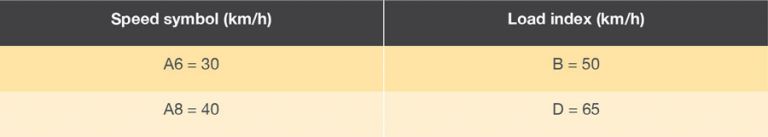

D: the speed symbol, ‘e.g. D = 65kilometres per hour’.

DW13A: Approved rim, permissible rims: W13A, W13A, W13, DW12A, DW12, W12A,

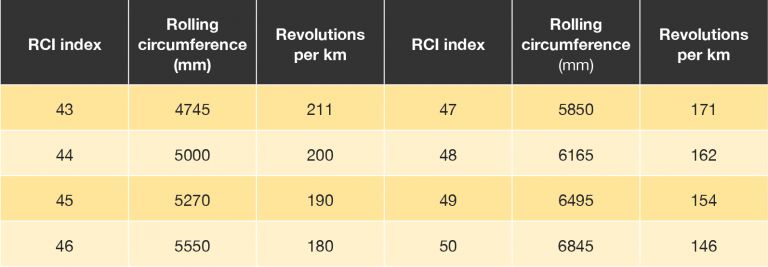

Rolling circumference: 5530mm

Load per tyre (single): maximum of 6500kg at the maximum pressure of 4.4 bar (64 psi) at 65km/h.

A specific code for the tyre tread pattern is not included here, but this code may need to vary for different situations. Often it may be listed as R-1, R-1W, R2, R3 or R4.

Tread patterns are discussed further in this module (scroll down).

Tyre categories

Standard tyres generally have an ‘R’ for ‘radial’ stamped onto them and no other symbols or codes.

Increased Flexion (IF) or Advanced Deflection Design (AD2™) are tyres that have sidewall flexibility which allows them to carry loads that are 20 per cent greater than a standard tyre inflated at the same pressure.

Similarly, the IF and AD2 tyres can carry the same load as a standard tyre, but at a 20 per cent lower inflation pressure. By reducing the ground-bearing pressure by 20 per cent, better flotation and less compaction will occur, while still maintaining traction in wet soil conditions.

Very Flexion (VF) technology offers even greater sidewall flexibility than ‘IF’: Very Flexion (VF), allows for a 40 per cent increase in load capacities at the same inflation pressure compared to a standard radial, as well as the ability to carry the same load at 40 per cent lower inflation pressures than a standard radial.

Unlike standard sprayer tyres, there are no additional load bonuses allowed for IF and VF tyres at slower speeds.

The load index and corresponding weights the tyre can carry

Tyres will display a ‘Load Index and speed’, typically as a three-digit number that corresponds to the weight that each tyre can carry at the recommended operating speed (see Table 2).

Examples of the load index and the weights able to be carried by the tyre

Load bonuses and self-propelled sprayers

The following information has been supplied by the Titan Tire Corporation, Iowa.

Typically, metric radial drive tyres that are rated for 25.0/30.0 miles per hour (40.2/48.3km/h) transport and service speeds can receive a ‘load bonus’ when travelling at slower transport speeds, for example:

at 32.2 kilometres per hour (20 miles per hour), +7% can be added to the load rating for transport and service;

at 24.1km/h (15mph), +11% can be added to the load rating for transport and service; and

at 16.1km/h (10mph), +34% can be added to the load rating for transport and service.

These load bonuses DO NOT apply to self-propelled sprayers for transport and service speeds.

The tyres used on self-propelled sprayers are treated differently to normal metric radial drive tyres.

Self-propelled sprayer tyres that are rated for speeds of 40.2km/h (25mph) or 48.3km/h (30mph) for transport service DO NOT receive load bonuses for slower transport speeds.

The load bonus is only applicable for field service (spraying speeds or use in the paddock).

For a self-propelled sprayer tyre rated for 40.2km/h (25mph)/48.3km/h (30mph), the load bonus at different spraying speeds (field service) would be:

at 40.2km/h (25mph), +7% can be added to the load rating (for in-field use);

at 32.2km/h (20mph), +14% can be added to the load rating (for in-field use); and

at 24.1km/h (15mph), +22% can be added to the load rating (for in-field use)

In summary, the operator can gain a 22 per cent load increase for in-field use, if operating a 40.2km/h (25mph)/48.3km/h (30mph) tyre at 24.1km/h (15mph).

However, you would not get the load bonus if you were transporting the same load down the road at 24.1km/h (15mph).

Tips

The operator must carefully assess the information provided by the tyre manufacturer regarding load bonuses before purchasing tyres, particularly for self-propelled sprayers.

Unlike standard sprayer tyres, there are no additional load bonuses allowed for IF and VF tyres at slower speeds.

Speed symbols used on sprayer tyres

The speed symbol is an abbreviation of operating speed: speed for a given load index an example is provided in Table 3.

Examples of speed symbols and load indexes used on tyres

Tread patterns for sprayer tyres

There are four tread patterns that are commonly used for sprayer tyres, which are given the codes R1, R1W, R2, R3 and R4.

Choosing the right tyre

Summary of tread patterns available:

R1 Drive wheel, regular tread

The R1 tread is used for general farming and typically provides the best traction in most soil conditions. The tread is an aggressive pattern for developing traction in hard to soft soil conditions. The tread void area is approximately 70 per cent of the total footprint for good cleaning in wet soils and good penetration in firmer soils.

R1W Drive wheel, wet traction tread

This tread pattern originated in Europe and has a 20 per cent deeper skid depth than R1. European tractors often spend a higher percentage of time on paved surfaces and the deeper tread increases tyre life. This tread depth is popular in Europe and is becoming more prominent in North American markets.

R2 Drive wheel deep tread

A tread pattern used in wet farming applications where the machine must run through mud and standing water. Typical applications are rice, sugarcane and high-value vegetable crops. The tread is twice as deep as the standard R1 tread. While R2 looks extremely aggressive, the typical 45° bar angle is maximised for cleaning in wet soils and is not as efficient for developing traction as R1 in general farming conditions.

R3 Drive wheel, shallow tread

This tread pattern is a non-aggressive pattern where minimal ground disturbance is required, such as for airports, golf courses, cemeteries, roadside maintenance, dryland combining, and on large heavy trailers such as manure and grain carts. The tread typically has a relatively closed tread pattern to evenly distribute the load, with void area in the 30 per cent range.

R4 Drive wheel, intermediate tread

A tread pattern typically designed for construction and light industrial equipment, such as backhoes and small end loaders. The tread depth is approximately 70 per cent of the R1 tread, and is designed for good wear on roads and reasonable traction on soils at a construction site. The tread-to-void ratio is typically 50/50.

Find out more

The article ‘Choosing the Right Tire’ can be found at: elibrary.asabe.org/data/pdf/6/crt2004/Lecture28.pdf

Tips

It can be a good option to look at tyres with an R3 or R4 tread pattern. The R4 tyre has less impact on the soil because the lugs are approximately 50% contact and 50% void (not touching the ground). Less aggressive tread patterns also displace less air, which may improve deposition near wheel tracks.

One strategy that has been employed by a number of operators is turning the tyres around on self-propelled sprayers, which results in pulling soil under the tyre, which can reduce soil damage, improve flotation and may make it easier to reverse out of a sticky spot.

Rolling circumference index

The rolling circumference index (RCI) is a number that corresponds to a specific rolling circumference (in millimetres). The rolling circumference is important for establishing the correct ‘lead’ for FWD: front-wheel assist and MFWD: mechanical front-wheel drive tractors. For more information on determining the ‘lead’, see section 5 of this module.

The rolling circumference may also be useful for calibrating wheel-based speed sensors.

Conversion from RCI index to actual rolling circumference

Rim size and type

All sprayer tyres must be fitted onto an appropriate rim type, ideally the rim that is recommended by the tyre manufacturer. For some sprayers it may be necessary to change the rim types to match the type of tyre that is required to carry the sprayer’s weight at the inflation pressures and speeds required by the operator.

Rim numbering information

Rim information explanation

42: refers to the rim size (42”) that the tyre is to be fitted to

DW: double well shaped rim (or drop centre contour). ‘W’ stands for single well shaped rim.

The different well types may make it harder or easier to install and remove the tyres.

16: is the width of the rim e.g. 16.0”. Tyre manufacturers recommend an approved rim, or permissible rim that their tyres are to be fitted to.

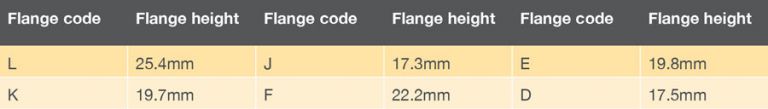

A: describes the rim flange height and contour. Tyres are manufactured to fit onto particular rim’s flanges (see Table 5).

Flange codes

Tyre beading pressure

Some tyres may have a symbol for the ‘tyre beading pressure’ moulded into the tyre to advise the tyre fitter what the recommended beading pressure is.

Bead pressure warning

Ideally the tyre will be left inflated at the recommended beading pressure for 24 hours (at least overnight) before the tyre is put under a load. This time allows the raised lines on the tyre bead to mould into and grip onto the rim.

Find out more

For more information go to: https://business.michelin.com.au/help-advice/fit-remove-agricultural-tyres

Toe in toe out

Machinery manufacturers provide a suggested toe in/out figure in the operator’s manual. Performing a toe in/out adjustment is very important in reducing steer tyre wear and maintaining correct auto steering performance.

The most accurate way to check and/or adjust toe in/out is to park tractor/sprayer on cement floor, check that the tractor/sprayer is level, check tyre pressure and move steering wheel to centre. Using a plumb bob establish the centre of the front and back of tractor/sprayer and mark the floor. Using a string line mark the floor from the front to rear of tractor/sprayer.

Place a large square on the centre line and check the measurement from the square to the centre of the tractor/sprayer rim. Check measurements on the rim centres and make adjustments as per operator’s manual.

There are other ways of checking, adjusting toe in/out but the above is the most accurate and takes out the anomalies of where the centre of steering wheel and power steering is.