Spray application manual

8 June 2025

Module 15: Weight, balance and tyres

15.6 Monitoring tyre pressure

Published 24 January 2025 | Last updated 20 January 2025

To improve tyre wear and boom stability, the operator needs to do whatever is possible and practical to have a well-balanced sprayer, ideally fitted with tyres that can carry the load at about 20 to 25 psi.

Tyre pressure needs be monitored on a regular basis. Having a calibrated pressure gauge that is regularly checked for accuracy is an essential tool for the spray operator.

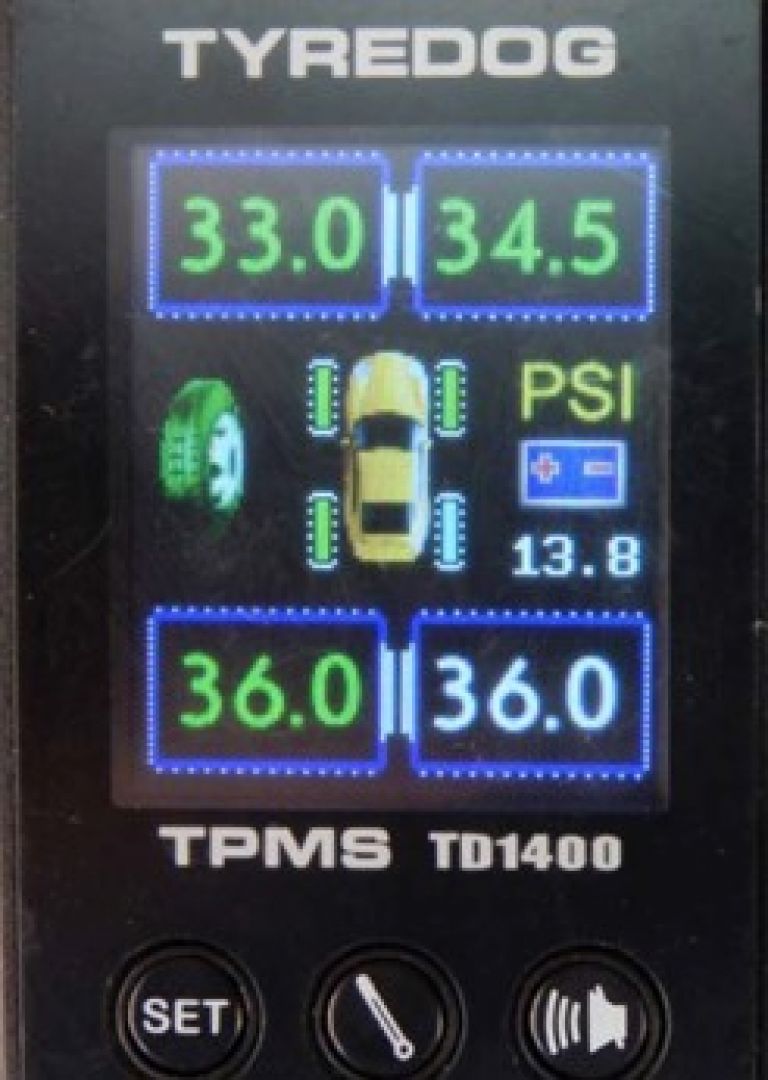

There are systems available that will allow the tyre pressure to be monitored from inside the spray cab, such as the TYREDOG™ system. This system operates a wireless sensor on the tyre valve stem, coupled with a receiver and screen in the cab.

Tyre tips for assessing tyre pressure

10 January 2025Tips for assessing tyre pressure. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: Okay, here’s a little tip that’s very handy. When you walk past a tyre and don’t have a pressure gauge but you’re wondering how your tyres are doing pressure-wise, just check the lug in the centre. The outside two lugs should be just touching the ground. That’s a really good rule of thumb if you don’t have a pressure gauge to know whether you’ve got enough pressure in your tyres.

Okay, let’s go to the front tyre now. This is a good example of an over-inflated tyre. You’ve got the lug not quite in the centre but close enough. Notice how the outside two lugs are off the ground? If you walked past this tyre without a pressure gauge, you’d know you need to let the pressure down so those lugs touch the ground. You’ll still need a pressure gauge, but this is a good guide. Yeah.

Tyre gauges require calibration

9 January 2025Tyre gauges require calibration. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: Something we found recently is that tyre pressure gauges aren't reading exactly as they should do. I've had a situation where a farmers guage the other day was 8 PSI lower than this gauge that had been checked against a calibrator pressure gauge at the tyre reseller. It's very very very important to have your gauges on the farm checked with a calibrated gauge in town.

TYREDOG™ screen in self-propelled sprayer cab

TYREDOG™ wireless sensor on valve stem

Find out more

For more information on TYREDOG - Wireless Tyre Pressure & Temperature Monitoring Australia

Controlled tyre inflation systems

The optimum set-up for the spray operator would be to have a system that can do both pressure monitoring, and automatic inflation or deflation, from the cab. Controlled tyre inflation (CTI) systems allow this to be done.

Where CTI is installed, adjusting tyre pressures for different load requirements, or travel speeds could be less of an issue, particularly if the sprayer is NOT using higher load rated tyres or the VF or IF type tyres.

Self-propelled sprayer tyre with controlled tyre inflation (CTI)

Close-up of self propelled sprayer set up (wireless device on the valve cap)