Spray application manual

9 June 2025

Module 4: Managing spray drift risk

4.2: Understanding the terminology used to describe droplet size and drift potential

Published 24 January 2025 | Last updated 20 January 2025

Spray quality classifications

The choice of nozzle and the spray quality (droplet size) that it produces can have a large influence on the level of control obtained. It will also influence the amount of spray that can exist as small droplets, which may remain in the air after each pass of the sprayer.

Spray quality classifications assigned by the American Society for Agricultural and Biological Engineers ASABE, formerly the ASAE) or the British Crop Protection Council or International Organization for Standardization (ISO) are based on measurements of the droplet size produced by a nozzle at a given pressure as compared to the outputs of standard reference nozzles.

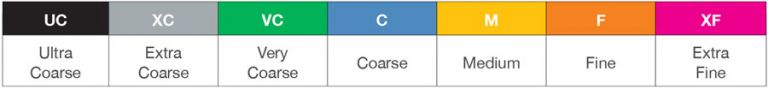

ASABE spray nozzle classification by droplet spectra

ASABE standard 572.3 describes the range of droplet sizes produced by a nozzle at a particular pressure. (Colours assigned to spray quality are NOT related to colours assigned to nozzle size.)

ASABE spray nozzle classification

Find out more

For more information go to Module 10: Weather monitoring for spraying operations.

While the ASABE, BCPC and ISO systems are not a direct measure of actual drift, they do provide a useful indication of the potential amount of spray drift that a nozzle could produce.

Generally, moving from one particular spray quality classification, to a coarser one should halve the amount of the spray solution that exists as small droplets capable of remaining airborne.

For example, a medium spray quality may have up to 20 per cent of the nozzle output existing as droplets less than 150 micrometres (microns), which are capable of moving with the wind. A coarse spectrum will have less than 10 per cent of the total output as droplets less than 150 microns, and a very coarse will have less than 5 per cent of the total output as droplets less than 150 microns.

Find out more

For more information on nozzle type, design and nozzle selection go to Module 3: Nozzle design and function and Module 5: Spray plans.

Reference nozzle outputs

The amount of spray that remains in the air after each pass of the sprayer will also depend on other factors, such as the conditions at the time of spraying, the boom height and the spraying speed.

Measurements and indicators of drift potential

Spray operators who are focused on reducing the number of drift-prone droplets through the addition of an adjuvant, or by changing nozzles, should seek information detailing the volume of nozzle output at different droplet sizes (microns).

Droplet size and indicative drift potential

Less than 100 micron = Highly drift-prone; Difficult to reach the target. Should be minimised where possible.

100-150 micron = May not reach the target. Can move off-target with prevailing wind. May remain suspended under inversion conditions. Susceptible to evaporation, thus further reducing their size and weight.

150 to 200 micron = Should make it to the target, provided boom height is low (50cm from target) and travel speed is less than ~18-20kph. Under hot/dry conditions, droplet evaporation may reduce size to less than 150 micron before reaching the target.

Above 200 micron = Generally expected to make it to the target and less susceptible to evaporation.

For an adjuvant or nozzle manufacturer to claim drift reduction you would expect to see data that shows a reduction in the number of small droplets, usually less than 150 microns. This requires information comparing droplet sizes before and after addition of the technology.

Caution needs to be used in evaluating this information as you need to be sure that the product is not just reducing the percentage (%) less than a given size by increasing the number of droplets that are generally too large for the intended target.

To make such an evaluation it is important to understand some of the scientific terms that are used to describe droplet spectrums.

Find out more

For more information on nozzles and spray quality go to Module 3: Nozzles design and function.

Scientific terms used to describe droplet size and drift reduction

A number of terms are used on labels, in scientific literature and in manufacturer’s technical brochures to describe the range of droplet sizes that can be produced by a nozzle. Some of these include:

μm = is the notation used for micrometers (microns). There are 1000 microns in a millimetre.

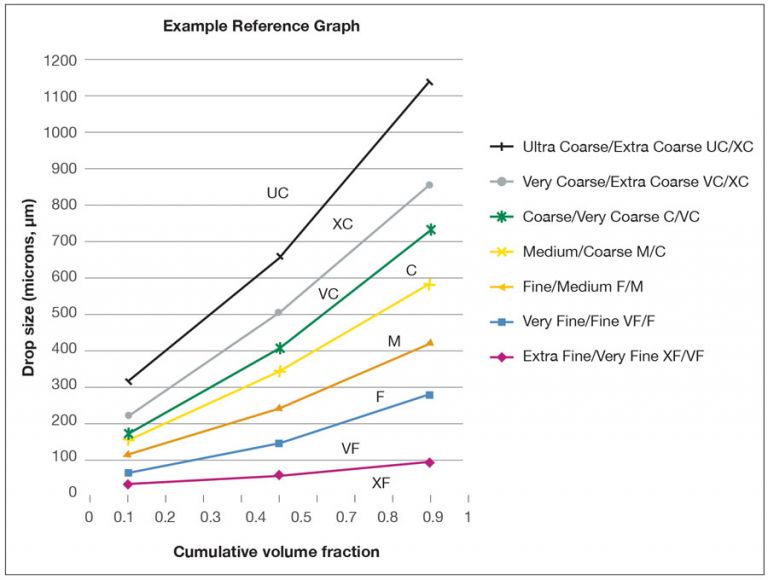

Dv0.1 = the droplet size (diameter in microns) at which 10 per cent of the volume will be smaller than this size. Larger Dv0.1 values indicate fewer drift-prone droplets will be produced. Dv0.9 = the droplet size (diameter in microns) at which 90 per cent of the volume will be smaller than this size.

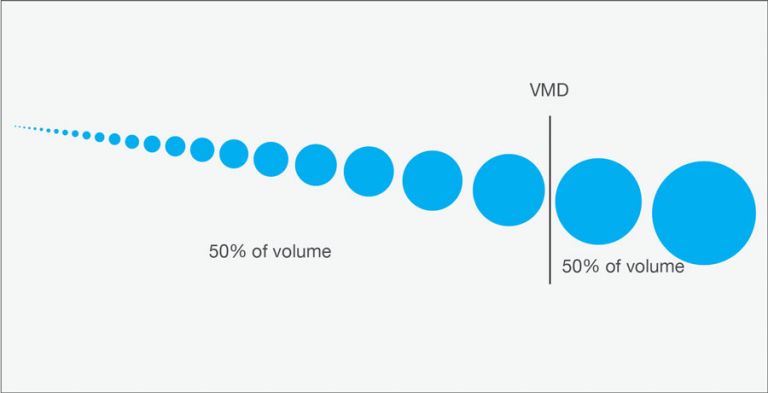

VMD = volume median diameter, this is the droplet size (diameter in microns) at which half the volume released from the nozzle will exist as droplets larger than this size, and half the volume will exist as droplets smaller than this size (see Figure 2). VMD is also referred to as Dv0.5 in scientific literature.

Volume median diameter

Span = a term used to describe the range of droplet sizes produced.

The span is a calculated value where Span = (Dv0.9 – Dv0.1) ÷ Dv0.5

If a nozzle had a calculated span of less than 1, this would mean that the range of droplet sizes produced by the nozzle would be quite narrow.

For example, if a nozzle had a VMD of 300μm, a Dv0.9 of 450μm and a Dv0.1 of 200μm, then Span = (450 – 200) ÷ 300 = 250 ÷ 300 = 0.833 (a very narrow range of droplet sizes).

If another nozzle also had a VMD of 300μm, but a Dv0.9 of 550μm and a Dv0.1 of 150μm, then Span = (550 – 150) ÷ 300 = 400 ÷ 300 = 1.33 (more typical of many hydraulic nozzles).

As the span increases in value above 1 this indicates that the range of droplet sizes is also becoming greater.

How VMD data can be misrepresented to suggest drift reduction

It is relatively easy to increase the VMD of a nozzle at a given pressure by adding substances that increase the number of large droplets in the spray solution. Such increases in VMD can occur without substantially reducing the number of small driftprone droplets that are produced.

Products that claim to reduce drift potential by increasing the VMD (Dv0.5) should only be taken seriously if they also provide data to show a significant reduction in the Dv0.1 without adversely increasing the Dv0.9 or span.

Large increases in VMD without reducing the Dv0.1 may actually mean that there will be fewer useful droplets produced for each litre of spray, and, in some instances, many of the droplets produced may be too large to be retained on some targets.

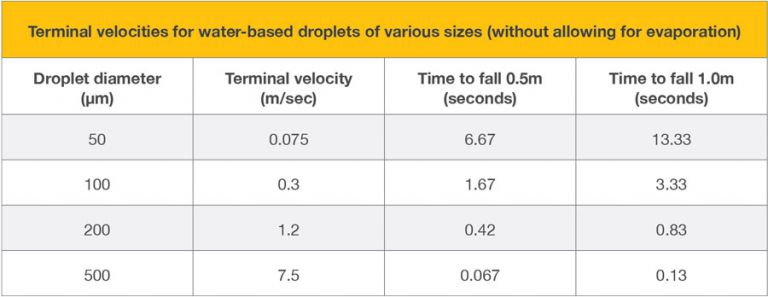

Terminal velocity of the droplets

Depending on their size, droplets will slow down at different rates as they move away from the nozzle. When they reach the point where they are no longer impacted by the forces that ejected them from the nozzle, but are under the influence of the external environment, they are said to have reached their terminal velocity.

Different droplet sizes will have different terminal velocities and will sediment towards the ground at different rates. Larger droplets hold their initial velocity for longer, have greater terminal velocities and will sediment towards the ground faster due to gravity. Smaller droplets lose velocity quickly and remain airborne for longer due to their lower mass.

Terminal velocities

Droplets that are approximately 150 micrometres (microns) or smaller in diameter tend to move wherever the prevailing wind takes them. This can occur both vertically and horizontally. Vertical movement can result from thermal activity or from the ‘wake’ effect around the sprayer.

Stop distance of the droplets

The distance a droplet is able to travel through still air after leaving the nozzle (unless intercepted by the target) is known as the ‘stop’ distance. In the absence of suitable air movement to help the droplets deposit, many smaller droplets will not reach the intended target, particularly when the boom height above the target is too high.

An initial droplet velocity of about 40 kilometres per hour is common for many air-induction nozzles as the droplets leave the nozzle. If you were to operate with a coarse spray quality, you could anticipate that there would be very few droplets produced that are 50μm in diameter; however, one to two per cent of the nozzle output may exist as droplets less than 100μm in diameter, and up to 15 or 20 per cent of the spray may exist as droplets less than 200μm in diameter.

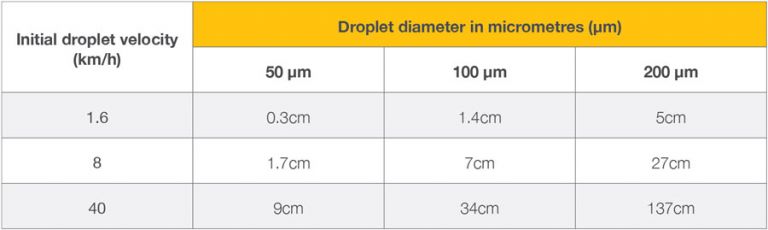

Consider the information in Table 2, which shows the distance (in centimetres) that droplets of different sizes can penetrate through still air after leaving the nozzle, relative to their initial velocity.

Theoretical distance

At a boom height of 50cm above the target and initial droplet velocities common for nozzles currently used, 100μm droplets or smaller would come to a complete stop in the air before reaching the target. Once they have stopped in the air, it is entirely up to the weather conditions what happens to them.

By comparison, droplets that are 200μm in diameter can travel 137cm before reaching their stop distance and are less likely to remain airborne.

When using a medium spray quality as much as 10 per cent of the sprayer output can exist as droplets less than 100μm in diameter. Unless there is a reasonable crop canopy or large standing stubble to catch these droplets, they are more likely to remain airborne and move off-target.

When using a medium spray quality, spray applicators could improve coverage and reduce drift potential by using a narrower nozzle spacing and height control systems that allow for booms to be maintained closer to the intended target.

In summary

When operating the boom at 50cm above the top of the canopy, droplets less than 150 micron will have lost downwards velocity before reaching the target and are therefore subject to movement with wind, inversions or from the wake behind the boom spray.

For a nozzle rated as Medium (M) spray quality, approximately 10-20% of the spray volume will be produced as droplets less than 150 micron, as therefore potentially subject to off target drift. For a Coarse (C) spray quality this will typically reduce to 5-10% of the spray volume.

When boom spray height is raised higher than 50cm above the top of the canopy, droplets up to 200 micron also have potential for off-target spray drift. This increases the volume of spray potentially able to drift to 20-30% for a Medium (M) spray quality and 15-20% for a nozzle rated as Coarse (C).

Under hot and low humidity summer conditions, droplets will be rapidly reducing in size immediately upon leaving the boom. This is especially the case with smaller droplets which have a much larger surface to volume ratio. Droplets that start around 150-200 micron may rapidly reduce in size under these conditions.

Manufacturer nozzle ratings are typically generated with water. Often the addition of pesticides or adjuvants can substantially reduce the average droplet size. Recent wind tunnel trial work suggests that many nozzles may reduce in spray quality by one full spray classification (sometimes more) with many common pesticide mixes. For example, a nozzle rated as Very Coarse (VC) may only deliver Coarse (C) when the pesticide / adjuvant combination is added.