Spray application manual

8 June 2025

Module 4: Managing spray drift risk

4.4: Factors that cannot be controlled, but must be managed

Published 24 January 2025 | Last updated 20 January 2025

The things that the spray operator cannot control, but must be able to manage, include the weather conditions at the time they want to spray, and the sensitive areas and crops that may surround the spraying location.

Find out more

For more information on managing the meteorological conditions go to Module 10: Weather monitoring for spraying operations.

DRT - Cloud observation

15 January 2025Observing cloud formations plays a part in spray drift reduction. Another video from GRDC's Spray Application GROWNOTES™ series.

This video appears in modules 4 and 10.

Bill Gordon: One of the things we can utilise when we're spraying is the visual clues and things happening around us, and certainly clouds are a great indicator of what's going on. When we see fluffy clouds—the cumulus ones that start to form in the morning—that means the inversion is generally broken up to about that level. Later in the day, they're also a good indicator of the onset of an afternoon inversion. So when we look at those clouds and they start flattening out on the ends, particularly in the distance, I'd expect we've probably only got another 20 or 30 minutes before the wind speed tends to drop off.

When the sun gets below about 20 degrees, the clouds are flattening out, and the wind speed drops, it becomes very dangerous for spraying because we can't predict what's happening. So, using visual clues as well as monitoring the weather is very important for spraying operations.

Managing weather conditions

The only way to manage weather conditions during spraying operations is to have access to reliable forecast data, to anticipate when changes are likely to occur, and to closely monitor and measure what the weather is doing at the application site.

Wind direction and wind speed are the best indicators of the potential risk of off-target movement of product during a spraying operation.

Weather

Find out more

For more information see the:

GRDC Fact Sheet ‘Hazardous surface temperature inversion’

GRDC technical manual 'Meteorological principles influencing pesticide application.’

DRT-weather-stations.jpg

15 January 2025Drift Reduction Technology - weather stations. Another video from GRDC's Spray Application GROWNOTES™ series.

| This video appears in modules 4 and 10. Bill Gordon: One of the things we need to do when we're spraying is to keep accurate records of what we're doing. Many farms have weather stations like this, and they're very good for keeping long-term weather data. The station's position is really important; you want it free of obstructions—not close to a tree—and ideally with about 10 metres of clear space around it, not located near buildings or structures where airflow might be interrupted. Where we place these stations is very important for their accuracy. However, from a label or legal point of view, we need to keep records where we're spraying. Unless the weather station is located within about two kilometres and in line of sight of the paddock where you're spraying, it might not be considered a legal record. The weather data should ideally be collected directly in the paddock where you're spraying. The records you need to keep include wind speed, wind direction, temperature, and relative humidity during spraying—not just at the start and finish. Essentially, each time you mix a load, you should be recording these conditions as you go and again at the end of the day. |

Label instructions will often include information about downwind buffers, no-spray zones and suitable wind speeds, which are a useful guide for applicators when planning upcoming spray jobs.

It is critical to read the product label to be aware of the required weather conditions, possible spray-drift restraints and record-keeping requirements.

With recent improved understanding of hazardous inversion conditions and advances in measurement tools, industry has invested in networks of meteorological stations designed to measure and predict the presence of a hazardous inversion. Once a hazardous inversion is in place all spraying needs to cease until the inversion breaks.

COtL (https://cotl.com.au/) maintains a network of base stations across the mid-north, mallee and riverland regions of South Australia.

The WAND network (https://app.wand.com.au/login), operated by GoannaAg with investment from GRDC and CRDC, covers key broadacre and cotton growing regions from southern NSW to central Queensland.

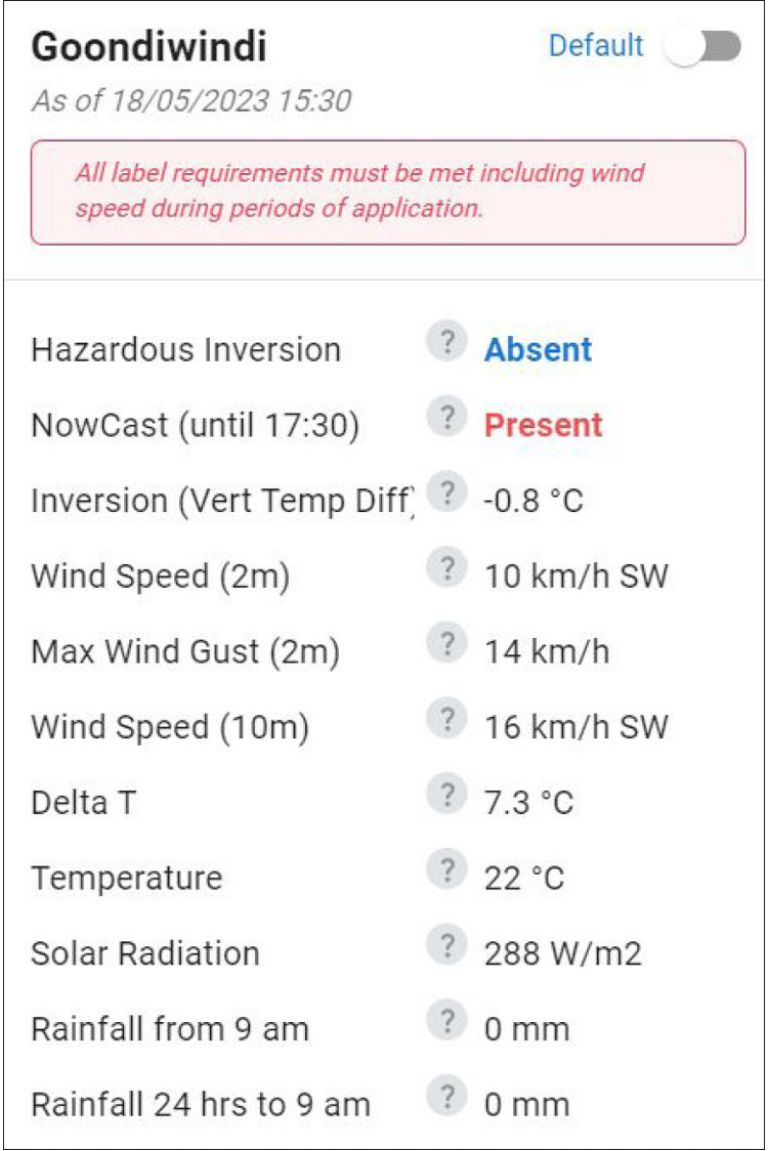

Depending on hardware installed at individual base stations, typically the site will provide a range of real time meteorological data to assist with spraying decisions. Additionally, sites provide information as to the real time presence or absence of a hazardous inversion, plus a prediction of the presence or absence of a hazardous inversion in 2 hours time.

Note in this example, there is a weak, but non-hazardous inversion currently present, despite conditions where the wind speed is 10-16kph. A hazardous inversion is predicted to develop within the next 2 hours. In this situation, the applicator may consider attempting to to complete the current tank load, while watching for further degradation of conditions, but would not to refill. Commencement of spraying should not occur until there is evidence that the predicted inversion has broken.

Meteorological information

Managing sensitive areas

Managing sensitive areas requires a thorough knowledge of what is around the area to be sprayed. Often this requires good communication with neighbours about what they have planted, or are planning to plant. It also requires the operator to do a bit of research. It is a good idea to talk to local advisers, who have knowledge about other crops in the area, and to access websites that may assist in identifying other sensitive areas.

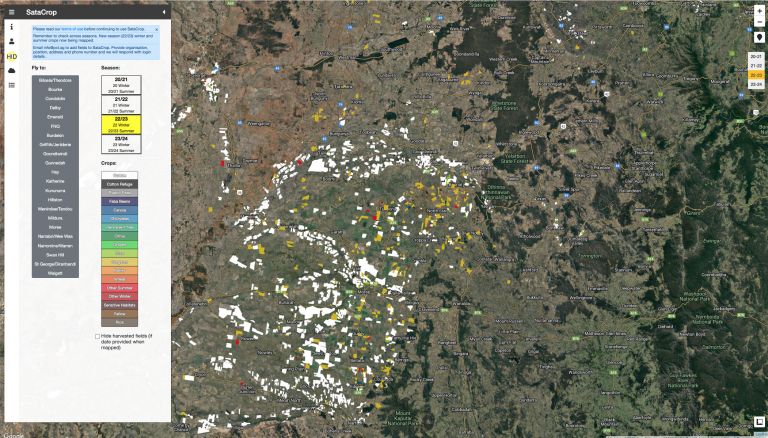

SataCrop

Useful websites include SataCrop

BeeAware

Useful websites include:

Google Earth – for rivers, streams and drainage patterns within your local catchment

Other useful information may be obtained by:

acquiring detailed maps of neighbouring properties;

following label requirements and other technical information from product manufacturers; and

accessing training and participating in stewardship programs.

Having identified potential sensitive areas, spray applicators need to consult label instructions for possible spray-drift restraints, downwind buffers and no-spray zones, and other directions for use, such as withholding periods.