Spray application manual

8 June 2025

Module 8: Calibration of the spray system

8.9 Fenceline nozzles (and other banded applications)

Published 24 January 2025 | Last updated 20 January 2025

Calibration of fenceline nozzles is critical to avoiding under or over-dosing. This is true for all nozzles used to apply bands.

The key to calibrating any nozzle applying a band is to know the sprayed width in metres.

Fence line spraying introduction

15 January 2025Fence line spraying introduction. Another video from GRDC's Spray Application GROWNOTES™ series.

| Craig Day: I just want to have a quick chat about fenceline spraying. Fence lines are becoming a major problem for us in broadacre agriculture. The issues with fence line spraying problems the green bridge, the issues with resistant weed build-up. Let's actually have a think about why we might be getting some of these problems on the fence line. If we consider a standard boom spray at 50 centimetre spacings as I've got here, my full rate occurs between two nozzles, so that means if I'm spraying around the boundary of every paddock this end nozzle has not got an overlap. So we're basically going around the edge of our paddock with a half rate. So not only the fence line but right on the edge of the paddock we have an issue. We can put an end jet on this sprayer, that can lead to some other problems. High flow sprayers A lot of new end jets that are on the market today have really high flow, they can be very effective tools but they need to be operated and calibrated correctly. If I put on this end section a high flow end jet, I run the risk of dropping the pressure in the nozzles that are in that line. In that fence line I'm probably already slowed down a little bit to avoid hitting the fence, so I've already had a lower pressure. I can't afford that pressure to be dropped too low for the jet. I want to have a quick look now at how we can separate this end jet and put it on a dedicated unit to do a better job on the fenceline. Possibly more timely after all our weeds have germinated on the fence line so we can get a better job, not having to do it when you're going around with that boom spray. Okay so here's the dedicated fenceline sprayer. I just want to go through a few Dedicated sprayers of the points that I've got on this particular unit. Obviously on drivers side to the fence. So here, so I avoid that half right on the edge, I've actually put an underband nozzle which is cutting off square here on the crop edge and feeding back in there, so I'm not running into that half right issue going back out in the crop which can potentially increase a little bit of drift. With 50 centimetre spacings, so that's going to come into our calibrations a little bit later on, we have the option to be a bit lower than this, but it's just set here for the moment. On the end I have a separate line running the end jet. Now it's really critical that we calibrate that and then match it back to our nozzle. A lot of the time these will put a lot of flow out, but if we throw them too far we can be lower than our mix or dilution rate and that happens quite often with people with their boom spray, so they may be going at 60 or 70 litres per hectare, but if they haven't checked this they could be down at 40 litres per hectare because they're throwing that too far. Really critical we check that out. |

Sprayed width per nozzle

For single nozzles that do not overlap with adjacent nozzles (e.g. fenceline end nozzles or even fan nozzles used for banded applications) use a tape measure to record the width of ground covered at the operating pressure and boom height.

Calibrating fence line nozzles and banded sprayers

15 January 2025Calibrating fence line nozzles & banded sprayers. Another video from GRDC's Spray Application GROWNOTES™ series.

| Craig Day: Here we want to have a look now at calibrating this end jet. We'll be looking at our speed, our flow rate and our width, how far it's throwing. Now when we set this rig up to go and do some fenceline spraying, we have 50 centimeter spacings here, we have to adjust our flow rate on this width to match what's happening with this rail. At 50 centimeters spacings on an 03 nozzle here, if we were doing 3 bar and 12 kilometres, that would be a hundred and twenty liters of water to the hectare. So what I want to do in this exercise I want to actually set this up to do a hundred and twenty liters of water to the hectare. Now our speed is going to be at 12 kilometers an hour, our pressure will be our 3 bar, the only variable we gonna have to play with here is our width. So we'll have to adjust how far were throwing this to ensure our hundred and twenty litres here, is effectively the same as here, and this is a trap for people with their boom sprays when you put one of these on you can find your dilution rate isn't actually going into the fence line as you think. Really pays to check in, look at that width, how far you're throwing it, collect the flow and do the calculations for litres per hectare. Some of the tools were going to need for the job is we're going to need our measurements, so we can get our width figure, some markers just to test and lay them out on the ground, we've already done a pressure test and we know that the pressure here and here is the same. We have a nozzle chart to refer to see how far or what our width is going to be. A little tip for you when you're driving and doing a fenceline sprayer, rather than relying on the speedo is just get the Navman or your TomTom and put it in the vehicle and you'll get a very constant speed. So we're talking this is a manual system so it's important that we do maintain a good constant speed. So we're happy with pressure, we now need to go through and we'll measure the flow rate with it. What I'll do there I'll just use a handy five litre container that's been washed out and I can hold it over the nozzle. Because this is a fairly high flow nozzle we need a container that's going to, can carry a fair bit. Then we can weight that and we'll have our litres per minute. Righteo, we're ready to measure our output, our flow rate from our end jet. Got my safety glasses on. I've already tared the container and recorded the tare result. Timekeeper is in position. Ready to start up and we'll Ok so we've got our 30 second grab of water there, done a quick calculation and including the container we're looking for 2.65 to see if our flow rates right for that 3 bar test. We've actually got our weight here of 2.65, which is equating to 2.65 litres. So we've got our flow rate, we're happy with that as per the chart. We come back across to our nozzle and we've looked at our chart at that pressure and at a 90 centimeter height to achieve a hundred and twenty litres per hectare, we have to have this nozzle throwing at that flow right 1.9 meters. That'll ensure that we've got a hundred and twenty litres here, which is going to match our 03 nozzle at three bar and 12ks, which is a hundred and twenty litres there. So the dilution rate is going to be the same on the back of the vehicle as it is throwing out into the fence line. So we're going to start it up, see what are wedded width is and make the adjustment back down to 1.9 metres if we have to. Ok so we've measured out our 1.9 metres here, we can see that we're actually overshooting the mark by quite a way, so we do need to make a quick adjustment just to bring that end jet back into that 1.9 metres. So we'll just get out shifter, get onto the jet and we're probably a lot better just there with that setup. Ok now we've got it all set up let's go and give it a run and see what it looks like. |

Fenceline nozzle sprayed width (W) will change if the height of the boom (Y) changes.

Once the sprayed width per nozzle is known, the same formulas can be applied to calculate the L/ha, regardless of the spraying situation.

Application volume in the treated area (L/ha)

Litres per minute per nozzle x 600 ÷ width (metres) ÷ speed (kilometres per hour)

Rearranging this formula, we can also determine the required nozzle flow rate, width or speed:

L/min per nozzle = L/ha ÷ 600 x width (m) x speed (km/h);

width (m) = L/min per nozzle x 600L/ha ÷ speed (km/h) ÷ L/ha;

speed (km/h) = L/min per nozzle x 600 ÷ L/ha ÷ width (m).

Calibrating and adjusting fenceline nozzles

The use of high-flow fenceline jets, such as XP (TeeJet®) or XT (Hypro), is becoming more popular.

Fenceline nozzles are often not adjusted correctly to ensure that the sprayed width matches the actual flow rate to deliver the same dose as the rest of the boom. These jets have the capacity to throw a significant distance (up to five metres) as well as applying a significant volume of water.

It is important to check the effect of these nozzles when attached to the end boom section as they can reduce the operating pressure of this boom section. This may result in efficacy reductions near the paddock’s edge when the nozzle is operating.

However, if set up correctly – plumbed as a separate section with the width recorded in the controller – high-flow jets can be valuable to maintain fenceline hygiene.

Steps for calibrating and adjusting high-flow fenceline nozzles.

Step 1: Set the boom to operating height and set the operating pressure.

Set the pressure to represent the actual operating parameters – remember that operators will often drive more slowly along fencelines to avoid damage. One way of achieving this is to enter a test speed and application rate into the rate controller to simulate field conditions.

Step 2: Use a calibrated testing gauge on the end section.

Turn the end jet on and check for a pressure drop in the end boom section. Test the pressure at the fenceline jet and record this pressure.

Step 3: Catch and weigh the volume per minute (L/min) delivered from the end jet.

Step 4: Determine the required sprayed width to match your intended application rate using the following formula.

Width (m) = L/min per nozzle x 600L/ha ÷ speed (km/h) ÷ L/ha

Worked example:

Using an XP 10R nozzle at 3 bar pressure the nozzle output was measured at 3.95 litres per minute.

Nozzle height was set at 70 centimetres. Spraying speed is 18 kilometres per hour.

The target application rate to match the rest of the boom is 90L/hectare.

Using the formula:

Width (m) = litres per minute per nozzle x 600 L/ha ÷ speed (km/h) ÷ L/ha

Width (m) = 3.95L per minute x 600 ÷ 18 km/h ÷ 90 L/ha = 1.46 metres

Step 5: Adjust the angle or orientation of the nozzle to achieve the required sprayed width at the target weed height.

Alternative method to calculation

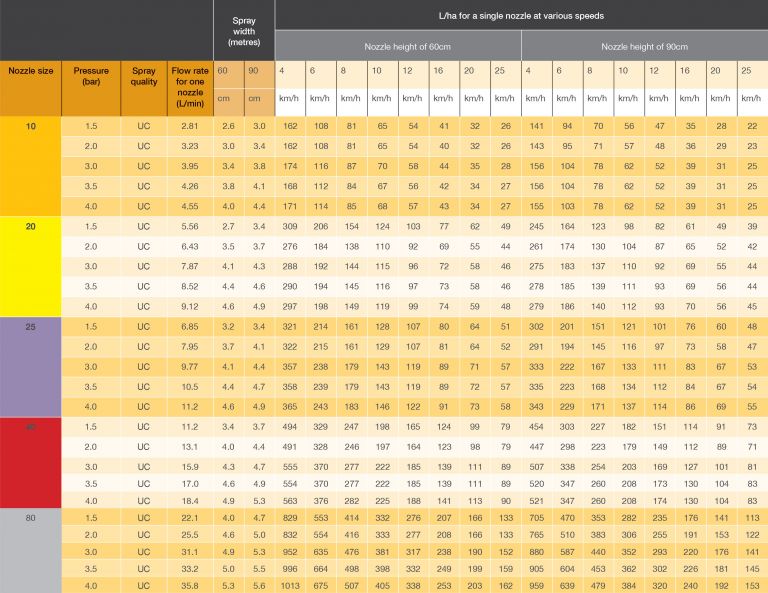

Where the nozzle height and flow rate match the manufacturers charts, they may be used to work out the applied rate.

L/ha for a single nozzle at various speeds