Spray application manual

4 June 2025

Module 13: Rate-controller functions and settings

13.5: Functions the operator should consider using

Published 24 January 2025 | Last updated 20 January 2025

It is important to spend time going through the controller manual before operating the sprayer and highlight important functions and features. Each controller will have a

range of useful functions that the operator, may not be aware of.

Two particularly useful functions that are common to many rate controllers are the simulated speed or test speed function and the automatic adjust function.

Simulated or test speed function

The simulated speed, function allows the operator to simulate various spraying speeds while the sprayer is stationary. This is very useful for calibration and pre- operational checks.

There are various ways different manufacturers identify the minimum hold function in their controllers, including in the following.

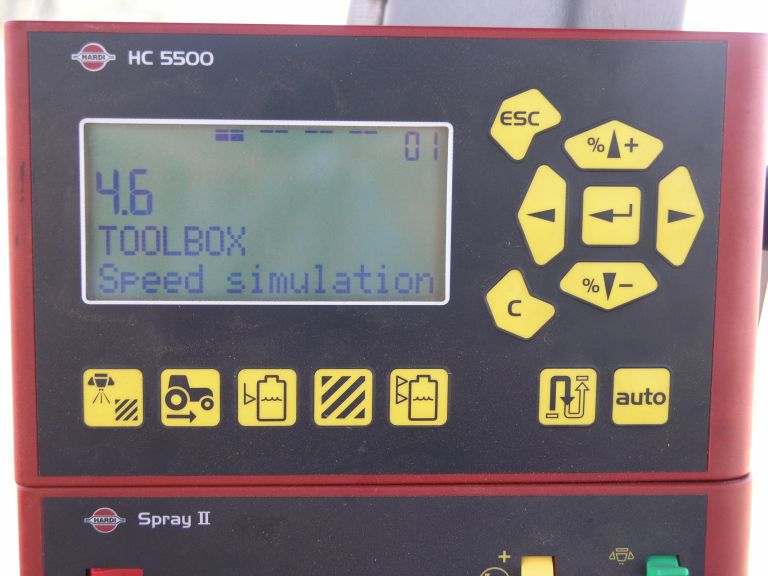

Hardi 5500 speed simulation function

Bravo 1805 speed simulation function

Checking controller inputs and settings

24 January 2025Checking spray controller inputs & settings is one of the many aspects of a spray operator's routine. GRDC's Spray Application GROWNOTES™ covers this ...

Craig Day: Ok well now we've completed the plan and the day hasn't turned around so we can't do any spraying, I'm going to use this time now to actually test this sprayer out. Before I actually use the spray plan to check out the test features in this sprayer, I want to record all the actual parameters that are in this sprayer. I want to look at the width, the speed calibration factors and the flowmeter numbers, so I can basically have them as a reference point if I do need to make any changes to the spray unit. So that would be the first place I'd start. So I go into the rate controller and I go into calibrations and I'd have a look at my speed calibration, get the constant out and record that down on the spray plan.

Once I've done the speed calibration number, I'll go now and take a look at the flow calibration figure, flow calibration constant and record it. 133.83 in this case, pulses per unit. Also want to make sure that we we haven't had any interruptions or changes made to the actual boom width, so go back into calibration and check our other parameter, which is going to be boom width. Go to width and that's all checking out right 555 and 20 metres in tow. Ok so we've gone and we've taken the speed constant, the flow constant we'll be able to use these in future calibration exercises. The boom width is a total of 20m, four sections in this particular unit, each section carrying 10 nozzles. So it gives us a total of forty nozzles.

Ok, so I'll just do a rough working example now which will relate back to our completed plan. We're going to average a test at 20 km per hour here, we have half a metre nozzle spacings. We have a 20-metre boom with 40 nozzles on it. We've said that we're going to be doing 60 litres per hectare. We quickly calculate that out - 20 by half a metre nozzle spacings, by 60 divided by 600 means my nozzle will be running 20 kilometres an hour doing one litre per minute. As we discovered earlier that's three bar, 1 litre per minute from an AI XR hundred and ten 025 lilac nozzle. Our speed is 20, so this is straight down our constant where we're trying to average the sprayer all day. Now we can look at some of the salary figures. At three bar each nozzle is giving us 1 litre per minute, so litres per minute multiplied by the number of nozzles will give us the figure that should appear in total flow. One by 40 equals 40 litres per minute. Speed we can move down into this summary area. Pressure we can move down and spray property was in the very coarse range. Once we've checked the sprayer in that part of the plan, we'll check the low-speed pressure and the high-speed pressure.

So with all that recorded I can now start to input the parameters from the plan. Now we've said that we're going to be doing 60 litres to the hectare, so I go to my panel when looking at the rate controller here you'll notice that I've litres per minute showing up on the screen. I already have inputted test speed here. Now I've done that through a toolbox feature. This is so I can effect this spray plan at our average speed of 20 km/h. So I come down the toolbox, and I go into a section called speed simulation in this particular unit, and I can input the value of 20 km/h as per our plan. Now providing the sprayer is in automatic mode, it will think it's doing 20 km/h, so it should start feeding back that important information from that summary area of the spray plan. So it show us flow, speed and litres per hectare.

That probably brings us to a consideration of what we're looking at on the panel. Our spray plan is running at 60 litres per hectare, so we go in we've got that inputted, so we've now got 20 km/h on the screen, an application rate of 60 litres per hectare, 4 nozzles on the rig at 20 kilometres per hour and 60 litres the unit will be running at about three bar. This will mean each nozzle is giving us about 1 litre per minute, so we should end up with a figure down the bottom here of about 40 litres per minute, and that's really critical when putting someone on a spray unit, especially an inexperienced operator when they're driving to have as much information available to them as is possible, because this gives them a back check of what's actually happening with the spray unit. From referencing here with flow to the corresponding pressure mark that you've got on your pressure gauge, it just reassures the operator that things are running as the plan has set out. Now that we've got the parameters of speed and application rate in the controller, we'll start the spray unit and will actually check through the test, following through our spray plan to see the numbers coming up on the rate controller.

Now for the moment of truth, we'll kick this thing into gear and see if it actually is doing what it should be doing. I've actually re-arranged the panel here to show us our program rate, so that's telling me what application rate I have set, the actual rate will cycle here. I've got my speed locked in here using a shortcut icon which is showing that 20 kilometres, that's in the test speed, and down here will have our leaders per minute. Now when you do a speed simulation test like that this is to be done in automatic mode with the hand flashing. Currently we're in the manual mode. So if I had the sections on I'll throw the master switch and I'll press automatic, and watch the numbers line up as we go. Once a sprayer settles down and should settle around 40 litres per minute, when it hits 60 litres per hectare and happy days it's managed it. So it makes sense why don't we test the slow speed and then try the high-speed, just to see that we've got enough regulation control to achieve the 25.6 and that we're achieving the right flow at both 2 bar and 5 bar at the extremities of our spray plan.

So the next step I'll do, still have our 60 litres per hectare as per the plan, I'll go back into a simulation into our toolbox and remember we can't get the point in here we're only going to get the round number, so we're looking for 16.2 as calculated but we'll just put in the speed of 16. 16 is now showing up on our iComm there, our flow will start high because of the position of where the regulator is at the moment and it will cycle down to somewhere around 32 to 33 litres - 32.4 is the exact figure, but remember we haven't got the exact speed in, and away we go. It's chasing down and about to hit the 60 and we're around cycling between 32. Yep settled around that 32 figure, so that's pretty good.

Next thing to do is why don't we test the high-end. So we've got to put the top speed in now off our spray plan, so we're now looking here for our 25.6, 5 bar and we're going to end up with a flow of 1.28 litres per nozzle and forty nozzles in total, so we're looking for a figure of 51.2 in the litres per minute flow figure here. So we'll go into toolbox again, we'll go to speed simulation and I can only input, we might input 26. 25.6 is the figure we're looking for, but this will give us a fair indication of what's going to happen. So our flow should be somewhere around 51 to 52 and a half. Started up, and the sprayer is taking a little bit of time to settle because we've taken it from a two bar setting now up to a five bar setting, and it's managed to achieve that there, and it's running 51 litres on the screen, so I'm fairly happy with the setup there, that that spray unit is going to be able to achieve what we're trying to achieve. The value of the spray plan is really critical. Having this information in the cabin can help any operator, but especially if you are trying to train someone that's inexperienced at spray application. This information can be given to them and they can drive to this with all the direction they need to ensure the spray job is going to be achieved as per the plan.

We've just used a speed simulation to successfully test our spray plan. Everything worked out pretty good. Before calibrating the sprayer I would use manual pressure to check the flow rate across the boom.

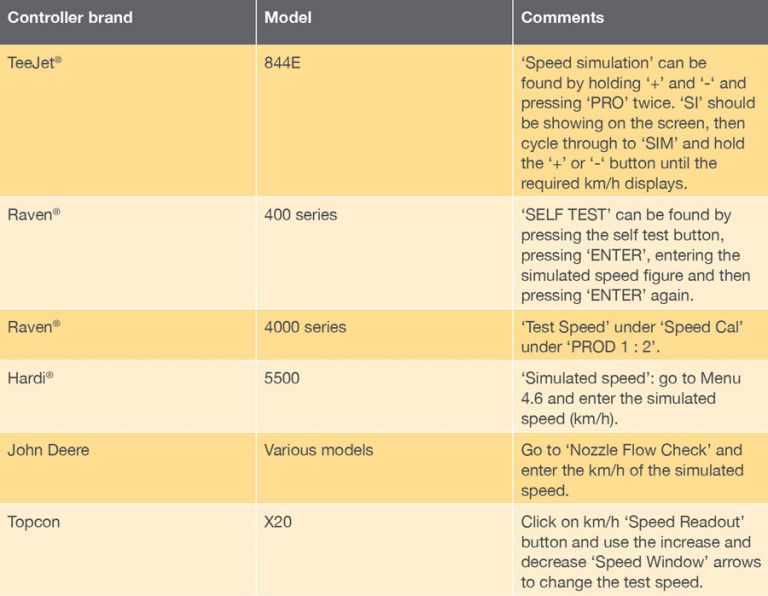

Finding simulated test speed function by model

‘Automatic adjust’ function for application volume

Another useful function of controllers is the ‘automatic adjust function’, which allows the operator to program a predetermined adjust figure into the controller to increase the application rate by a certain amount, either by a known L/ha or by a percentage increase of the L/ha.

For example, if the automatic adjust figure is set at 10L/ha and the spray operator decides to increase the application rate because of a heavy patch of weeds, the operator can push a switch or button to adjust the application rate (e.g. go from 70L/ha to 80L/ha). Then after passing the heavy patch of weeds, push a switch or button to resume the rate originally programmed into the controller.

Using this function should only be considered in situations where the applied rate is less than the maximum rate permitted on the product label, and the increased rate will not exceed the maximum label rate.

Pressure adjust in pulse-width modulation systems

With many pulse-width modulation systems, the operator has the ability to set more than one pressure while still being able to achieve the target application rate. This function allows the operator to change droplet size without changing nozzles, provided the selected duty cycle remains within the useful range.

Find out more

For more information on pulse-width modulation systems, go to Module 17: Pulse width modulation