Spray application manual

15 March 2025

Module 13: Rate-controller functions and settings

13.3: Settings available on common controller types

Published 24 January 2025 | Last updated 20 January 2025

Most rate controllers will come with a range of standard features that allow the operator to customise when warnings or alarms register. The sensitivity of regulating valves and settings will ensure the nozzles can function correctly at low speeds (minimum setting).

Alarms

Alarms can be set up to be audible or visual, or both. There are many different alarm settings in each brand of controller. Always consult the controller manual to determine which functions are available on the model you have.

Common examples of alarms that may be set or adjusted by the operator include:

low tank level reached;

outside the programmed application rate;

maximum speed or pressure reached; and

minimum setting reached.

Example of a tank volume warning

Tip

Don’t assume that the tank capacity is exactly as stated by the manufacturer. Calibrating spray tanks is very important. Markings or graduations on the tank are often not correct, and most manufacturers state they are only a guide. Too many spray operators change the flow meter calibration figure to match the perceived tank capacity, which may impact on the accuracy of all future applications.

Minimum settings

For Standard pressure based sprayers (not PWM), setting a minimum pressure, speed or flow (total flow or litres per minute per nozzle) at which the rate controller will not drop below when you reduce your spraying speed can be very useful to ensure nozzles continue to work effectively (with PWM systems setting a minimum duty cycle will have the same effect).

If you are not sure if the minimum setting has been programmed into your controller, you should see the L/ha on the screen increase above the programmed L/ha as you slow down; generally this will indicate that the minimum hold has been engaged.

When determining what the appropriate minimum setting should be, be aware that once the controller engages the minimum hold, further reducing the spraying speed will result in overdosing.

It is a good idea to match the minimum setting to the type of nozzle being used and to allow large enough headlands to minimise overdosing. A spray plan will help to identify suitable settings for different nozzle types.

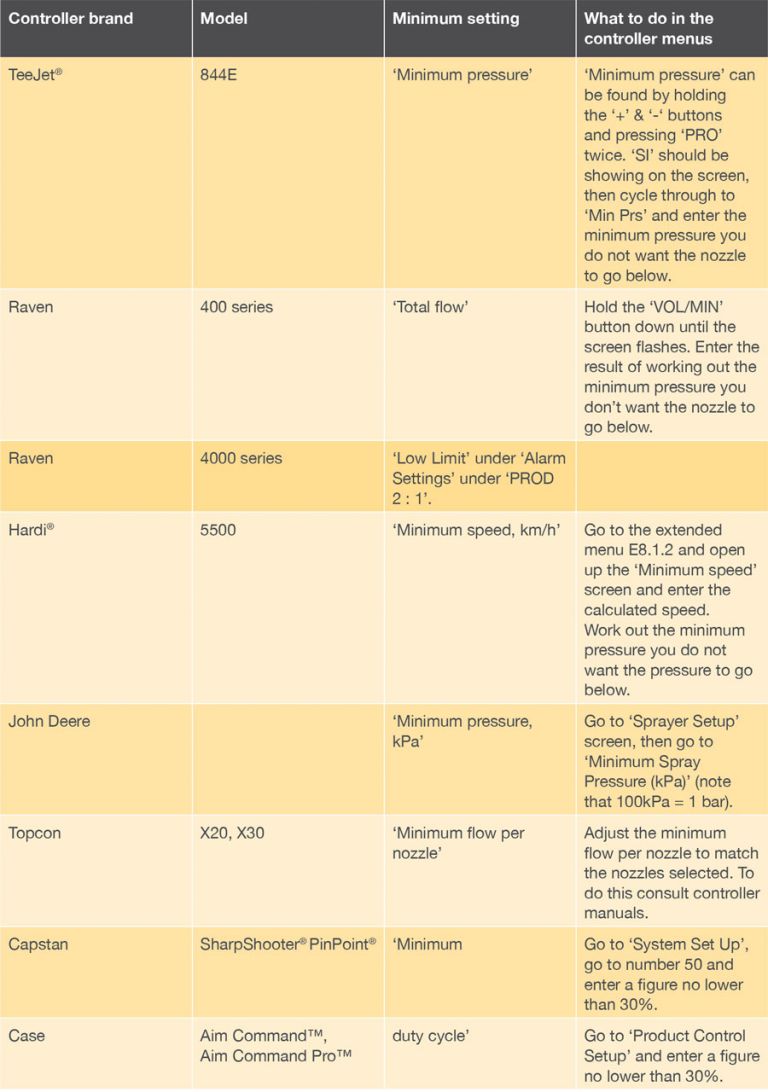

A number of manufacturers identify the minimum settings in the controller by different names, three examples are shown below.

Tip

Check that the controller can go down to zero output by putting the controller in manual with the spray system running, then turning the boom section on and pushing switch/button to lower pressure/flow.

Using a minimum setting in the rate controller

8 January 2025Using a minimum setting in the rate controller. Another video from GRDC's Spray Application GROWNOTES™ series.

Craig Day: Righto, one thing we haven't done yet is set the minimum setting. Now this is where the spray plan really comes into its own. We're allowing this spray setup here to operate down to 2 bar. Now, I don't want to stay down with that pressure for very long at all, but that's where I've set the minimum to be. That's given me a low speed of 16.2 k, so now I want to go in and set a minimum speed so the spraying will keep going if I have to slow down below 16.2 k. At 16.2, I'm doing 2 bar, so I'll just come a shade under 2 bar and put a minimum speed in of about 15.8, in case I have to slow down to that point, and the sprayer will keep regulating effectively. The spray goes back to manual when I hit that speed. It will keep that pressure until I speed back up past my 16.2 k, and the regulator will take over again.

To do this, we'll need our actual product manual, as it varies across controllers. Some controllers will allow you to set a minimum flow rate, this particular unit has a minimum speed, and others may have a minimum pressure.

From a previous plan, I’ve got a low-speed set at 8.5 ks, so I'm just going to move that up and make it 15.8. It's really critical to remember I’ve done that now, as one of my other settings was down at 8.5 for some slow, rough work. If I go and try to spray that again, the sprayer won't regulate down there, so I have to record that, write it down, and remember I’ve set it. The spray plan is a great place to record the minimum speed setting, so I’ve just written it down here: 15.8 k, set on the 12/5/2015.

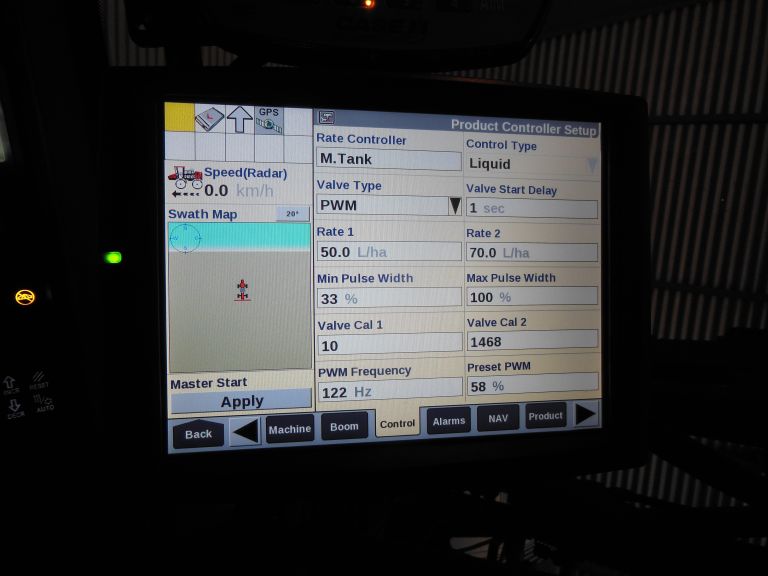

John Deere Screen controlling a Raven rate controller

Hardi® 6500 E8 minimum speed setting

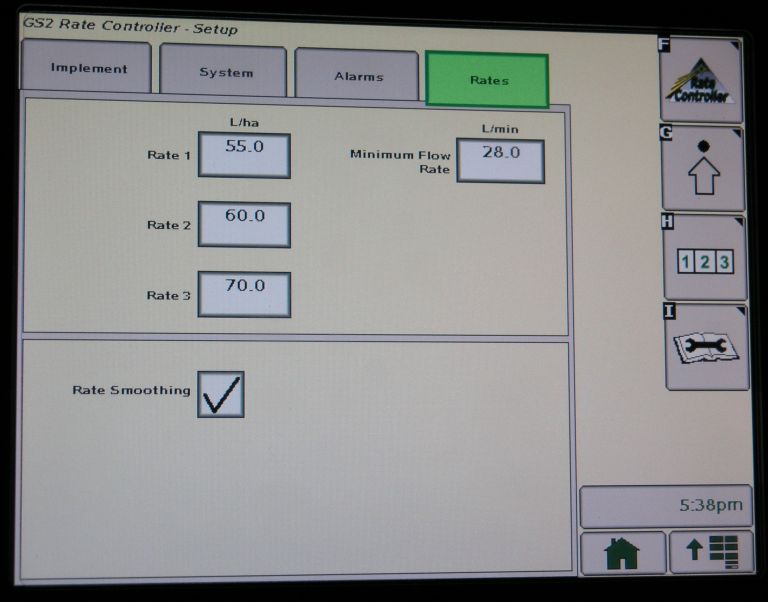

FarmScan® slow hold function

Tip

Caution needs to be exercised when determining where to set the minimum hold function when applying residual herbicides or other products at the maximum label rate. Operators should carefully plan spraying speed and the size of headlands to minimise the amount of time that the minimum hold function will engage to avoid possible overdosing. Preparing a spray plan to work out appropriate speeds and pressures is critical for minimising overdosing.

Common rate controller types and minimum setting requirements

Aim CommandTM minimum duty cycle setting