Spray application manual

5 June 2025

Module 14: Boom stability and height control

14.2: Importance of nozzle height

Published 24 January 2025 | Last updated 20 January 2025

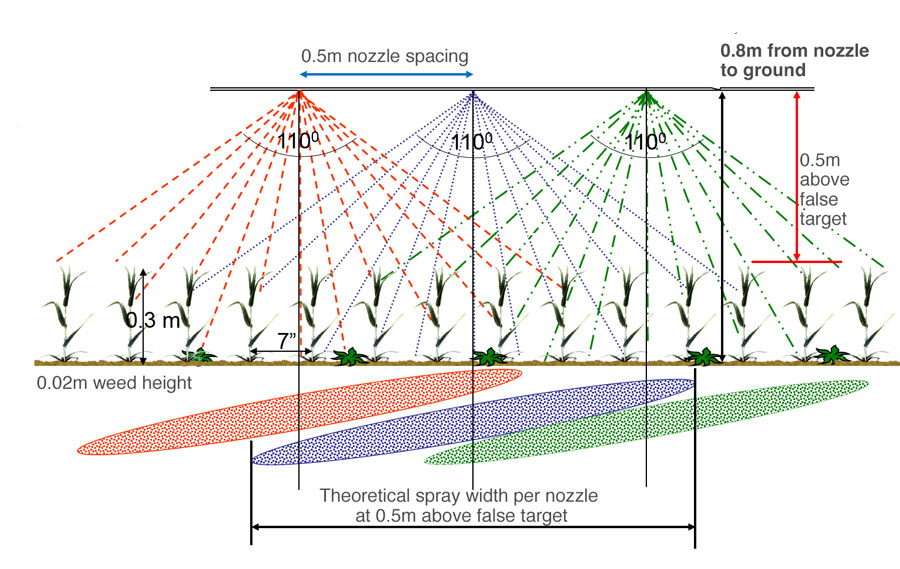

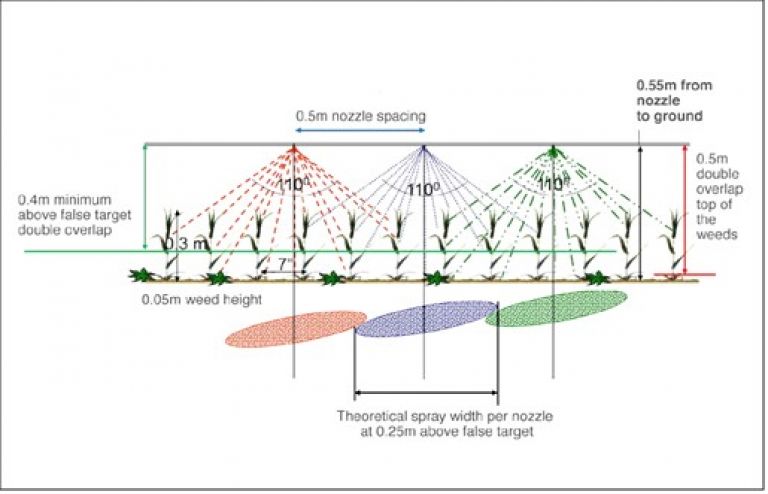

For broadacre boom spraying, the boom is normally fitted with nozzles that produce a tapered flat fan spray pattern and are designed to be operated with a double overlap of each spray pattern to achieve a uniform spray deposit across the width of the boom.

The ideal height above the target (or false target, such as stubble or crop canopy) for nozzles with a tapered flat fan spray pattern is where the nozzles achieve a double overlap. The double overlap occurs when the outer edge of the spray pattern reaches the target directly below the adjacent nozzle on the boom (Figure 1).

As the angle of a nozzle’s spray pattern reduces (for example, going from a 110° nozzle to an 80° nozzle), the height of the nozzle above the target or false target needs to increase to maintain the overlap.

The ideal height above the target or false target

Maintaining the boom height below the point where a double overlap of the nozzle spray patterns is achieved may result in variations in the application rate across the boom, potentially resulting in some targets being overdosed below the nozzles, while other targets between the nozzles may be under-dosed (Figure 2).

Wrong height above the target leading to uneven application

Establishing an appropriate nozzle height

To establish an appropriate height for the nozzles above the target or false target, the operator needs to know the angle of the nozzles’ spray pattern and the nozzle spacing.

Once we have this information we can use Table 1 to look up the required height above the target or false target.

Nozzle spacing

The nozzle height above target or false target indicated in Table 1 (that is, 0.35m for a 110° nozzle) is a calculated or theoretical height only. Factors such as lower nozzle pressure, increased spraying speed and increased wind speed may cause the nozzle spray angle to be narrower, so generally a slightly higher boom height is used. Offset or 'twin' nozzles will have a different spread and therefore a different theoretical height for double overlap.

Typically many users set the boom height at 50cm when using 110o nozzles on a 50cm spacing to ensure double overlap under varying field conditions.

Table 1 demonstrates that for most commercial spraying operations, lacking overlap is unlikely to be an issue in most situations.

Running booms at excessive height above what is required for double overlap substantially increases drift risk. If booms must be operated at higher heights above the target (or false target) then consider using narrower fan angles, especially if the nozzles are on 25cm spacing.

Narrower fan angles are also preferred for pre-emergent herbicides where the target is the soil. Having more droplets traveling closer to vertical results in less foliage interception and more spray deposited onto the soil.

After selecting the appropriate nozzle angle, the spray operator may still need to do a physical check to make sure the nozzle is at the optimum height above the target or false target.

Set the boom height at the determined height above the ground (pretend the ground is the target or false target) and have the nozzles operating at the intended spraying pressure. Stand upwind from the spray patterns, ideally with the sun shining on the spray pattern from behind.

The nozzle spray angle (spray pattern edges) should make contact with the ground directly below the adjacent nozzles. When this overlap occurs, the height above the target or false target for this particular nozzle at the intended operating pressure has been established.

Nozzle height above the target or false target may change when the nozzle pressure changes. For example, when spraying at slower speeds the nozzle spray angle could be narrower.

Tips

Install a piece of hose on each wing of the boom between the last two nozzle bodies. Put a piece of tie wire up the hose and out through a hole down the hose to make it easier to attach the hose to the boom. Cut the hose to the required height above the target or false target. It is a good idea to use a piece of hose even when using automatic boom-height systems.

If using half nozzle spacings (e.g. 0.25m) in combination with a multi-step nozzle system, and each step utilises different orifice size nozzles, the boom still needs to be operated at a height to match the single nozzle spacing (e.g. 0.50m). The boom can only be lowered if the same orifice size and spray angle nozzles are being used on all nozzle bodies.

Adding target-selectable sprayer systems onto the boom can place added pressure on the boom stability.

A piece of hose attached to the boom to indicate height

The impact of nozzle height on spray-drift potential

Increasing the boom height may increase the potential for spray drift to occur. All nozzles produce small droplets that are capable of remaining in the air. Droplets that are less than about 200 microns in diameter will slow down quickly after leaving the nozzle, so increasing the boom height increases the likelihood of those small droplets remaining in the air, which increases the potential for spray drift to occur.

Increasing the boom height from 0.50m above the target to 0.70m can increase the amount of spray remaining airborne by up to four times, and at one meter above the target this can increase by a factor of 10.

Find out more

For more information on droplet behaviour and spray drift management strategies, go to Module 4: Drift management strategies.