Spray application manual

5 June 2025

Module 14: Boom stability and height control

14.4: Systems for maintaining boom height

Published 24 January 2025 | Last updated 20 January 2025

Any height-control system fitted to the sprayer must be compatible with the boom centre and the terrain on which the operator intends to conduct spraying operations.

Maintaining optimum nozzle height can be helped by rigid touchdown wheels, hydraulic touchdown wheels, automatic (electric hydraulic) touchdown wheels and sensor-based automatic boom-height control.

Auto boom height not working properly over contours

Touchdown wheels

Touchdown wheels, also known as ‘jockey wheels’, are fixed wheels attached to the boom to prevent the boom striking the ground and for maintaining correct nozzle height. They are a good option to help with boom stability if the boom centre is able to roll.

Ideally, touchdown wheels are mounted two-thirds of the way out along the boom on the outer section, before the break away. The wheels need to have some type of cushioning device or independent suspension to reduce the impact on the boom when there is heavy contact by the wheels with uneven ground.

It is important to have the ability to adjust the wheel height up and down to be able to match the required nozzle height to achieve the double overlap at the target or false target. It is also useful to have the ability to move the mounting bracket sideways to match different crop configurations, and mounted near a boom bracing point.

Example of a touchdown wheel

Touchdown wheels with automatic height adjustment

There are two options for installing touchdown wheels with automatic height adjustment: hydraulic or electric hydraulic. When using hydraulics in combination with the touchdown wheel, there is an additional hydraulic block that is adjustable so when the pressure is reduced in the hydraulic line (for example, due to the wheel lowering when following the ground into a hollow), the boom wing ram is raised. When the wheel goes over an obstacle, the ram will do the opposite. This system works very well, particularly for booms that have a pendulum boom centre.

Using electrics and hydraulics, there are limit switches placed on the touchdown wheel suspension that send signals back to the hydraulics to raise or lower the boom.

In both examples, the boom wing lift rams may need to be replaced with longer rams so the boom can go below the horizontal when required.

Hayes auto boom height using wheels and a hydraulic load sensor on the ram

Tips

Install the touchdown wheel mounting bracket two-thirds of the way out along the boom from the centre of the sprayer, just past the outside fold (not the breakaway) and at a point where the bracing bracket can be mounted from the top to the bottom of the boom. Having the touchdown wheel outside the fold will have the wheel facing out when the boom is folded if using a rear-mounted boom.

Make brackets that allow the touchdown wheels to be moved along the boom to match the crop inter-row.

Do not have a rigid mounting point for the tyre, rather a suspension system similar to the back wheel on a motor bike. One possibility is a shock absorber, but a coiled spring could also be used.

Home-made touchdown wheel ‘with suspension and adjustment’ on Hardi® boom

Auto height control using sensors

Auto boom height using sensors is the most popular system for improving the boom’s ability to maintain the optimum nozzle height above the target or false target. Sensors are often standard equipment when you purchase a new boom sprayer.

Electronic height sensor

Height-control-systems-touchdown-or-jockey-wheels

8 January 2025Height control systems - touchdown or jockey wheels, Another video from GRDC's Spray Application GROWNOTES™ series.

Bill Gordon: This standard boom doesn't have any high control system fitted, we're relying on the stability of the boom to actually stop it from striking the ground. The one thing that can be fitted to a machine is something like a jockey wheel here that will stop the travel and reduce the boom strikes, the other thing this has fitted is a rail on the outside as well, this is probably an original feature, this is something the grower has actually added. So this is a complete manual system to stop boom strikes, pretty cheap and pretty effective. This can be coupled with something like a hydraulic load sensor in the ram, so that when the boom goes down and the wheel takes the weight can actually reverse the flow in the hydraulic sensor and just lift the boom gently, so this is a bare minimum cheap cost. The next step might be something like load sensors on hydraulic rams which work well on booms that have some sort of cable tie or something that will stop them going back when the wheel strikes, or the next step after that is something like an ultrasonic sensor out from the boom that detects the height as you're going along.

There are several brands of height-control systems available. Generally, manufacturers or dealers will use one brand over another on their machines due to distribution agreements.

The auto height-control sensors work by sending out an ultrasonic signal, which is reflected by the ground, the crop canopy, or a combination of the two. The time taken for the signal to return to the sensor indicates the distance from the target to the sensor. Factors such as travel speed, the sprayer or boom suspension, positioning of the sensor and the presence of stubble may impact on the accuracy of some systems.

Many of the sensor units have the ability to select between detecting either ground or crop and it may be important for the operator to ‘tell’ the height control systems which one is being detected during the spraying operation and calibration.

Sensors have the ability to simultaneously detect both crop and ground at the same time, which greatly increases their accuracy and the stability of the height-control system in some situations.

Auto-height-control-grower-experience

8 January 2025Auto boom height control, a grower's experience. Another video from GRDC's Spray Application GROWNOTES™ series.

Bill Gordon: Ok I'm with David Gooden and we're just having a quick look at his autho height control system and some of the things he's come across in setting it up and make sure it's running well. So when you are setting up David what are some of the things you've come across in getting your auto height to work really well?

David Gooden: Well the main thing is to calibrate, the feature that I've found the best to stabilize the boom was in setting up the minimum pressure for the hydraulics so we've increased the minimum pressure from about 65 or 70 percent up to 85 percent and by doing that we've got the boom is running more stable. It was unstable before we have one side lifting the other side counteracting so it's a it runs a lot more stable now we're not getting that counteracting on the other side.

Bill Gordon: Okay great thanks David.

Factors that may affect the ability of the auto boom height to function correctly may include:

the boom centre design;

hydraulic capacity of the sprayer;

sensor location;

boom roll;

tyre pressure;

sprayer suspension;

boom suspension;

boom centre tilt;

the ability of the boom centre to move freely (not rubbing on the wear pads); and

the auto height controller software.

Tip

If considering retrofitting an auto height-control system onto an older trailing rig, make sure the tractor has enough hydraulic oil flow capacity to operate the system.

Auto height sensors and their position on the boom

The position of the sensors along the boom is important to how well they may perform.

Auto-boom-height-systems

24 January 2025Auto boom height systems. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: Auto boom heights are great, but they're only as good as the setup. In this particular one the sensor was located far too close back here, and the beam was actually picking up on the steel here and giving a false reading. We had to redesign this whole bracket to get the sensor out a certain distance as per the manual, and also we had to get it high enough - the correct distance from the bottom of the nozzle to the sensor. Once we did all that, this thing worked beautiful. One of the big challenges was that we had to make a bracket that when you folded the boom, that it didn't foul up the boom.

Norac auto boom height sensor on a Miller boom

The ideal set-up on a wider boom would be to have five sensors: one for the centre section, one on each wing and one on each of the breakaways.

The two wing sensors may need to be moved when spraying contour country, so the boom does not get confused when one sensor is picking up the top of a contour and the other sensor is coming up to or going past the top of the contour (this may take a little bit of trial and error).

Each sensor should be mounted where it will not be damaged when folding the boom and where the field of view will not be obstructed by the spray pattern of the nozzles, particularly offset or twin nozzles, as per the manufacturer’s recommended height above the nozzle and distance out in front of the boom.

Nozzle spray patterns can cause false readings, where the boom may raise substantially, which can also occur when slowing down with reasonable tailwinds.

Tips

For optimum performance of the auto boom height-control system, consider having five sensors, especially with wider booms and when spraying paddocks with contours.

Some automatic boom height system manufacturers require the sensor to be serviced after a specified number of hours of use.

Calibration of sensors

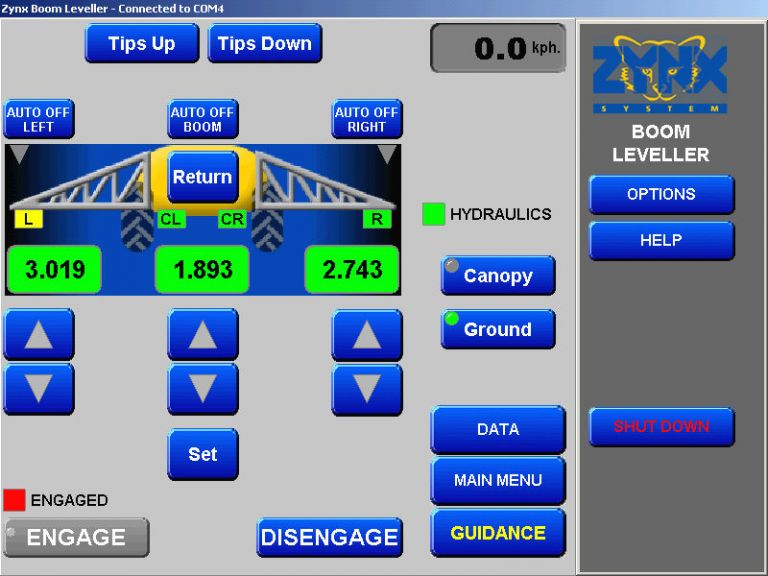

It is very important to perform the ‘auto calibration’ function in the auto boom-height controller. This must be done on level, bare ground and requires measuring the distance from the nozzle or sensor to the ground as per screen example (page18).

Record all of the auto boom function settings, including the date and comments, before making any changes, and always update your settings’ records when changes are made.

Make sure the boom is full of liquid before doing the sensor calibration, as this may change the balance from empty.

Only perform an ‘auto boom’ calibration after the hydraulic oil is at operating temperature after doing a few laps in the paddock using the auto boom-height system. It is a good idea to phase the rams before doing the auto calibration. Always complete an auto calibration after changing the hydraulic oil.

Topcon ZYNC boom leveller screen display

Tips

Some brands of auto boom height require the sensor serial numbers to be in sequence from left to right, with the lowest sensor serial number on the left to the highest serial number sensor on the right.

Turn the auto boom height system off when the boom is folded in the cradles during travel.

Check that the settings are in metric. If working physically in imperial, check that settings are exact conversions from imperial to metric.

Only ever change one setting at a time.

The auto boom height system may have to be switched into ‘manual’ over extreme surface undulations to prevent it making decisions when sensors are out of range.

Make sure height figures on the monitor change when the boom is raised and lowered.

Before commencing spraying, physically test sensors by placing a hand under the sensor.

Hand under sensor to check response