Spray application manual

4 June 2025

Module 14: Boom stability and height control

14.3: Boom centre design and functions

Published 24 January 2025 | Last updated 20 January 2025

There are a range of boom centres that are employed on modern sprayers. These include rigid, pendulum, trapeze, inverted trapeze, and a combination of pendulum and trapeze.

Boom-stability-rigid-boom-centres

8 January 2025Boom stability - rigid boom centres. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: What I want to show you on this boom spray spray is what we call a rigid or fixed boom centre. It has no pendelum or trapese. So this point here, has got a bar across the top down to there and there's no pivot point in here. So it's a rigid boom section. Where others will have what we call a pendelum, there'll be a pivot point there. Other manufacturers have a strap down here, what we call a trapese boom. The reason this is important is we want to isolate the impact of the tyre on the boom. So when you have a rigid section like that you've gotta have a very good tyre system and suspension system to stop having an impact on the boom wing.

Rigid or fixed boom centres

For standard boom spraying, fixed or rigid boom centres can have an impact on the boom height, and therefore the nozzle height, particularly when sprayer tyres go over uneven surfaces.

The stability and level of the boom will greatly depend on the chassis and suspension of the sprayer itself, which can make it hard to maintain the optimum nozzle height. Generally, rigid boom centres are better suited to sloping country than self-levelling booms.

Fixed centres may be useful if the operator is considering carrying extra weight on the boom, such as target-selectable units or shielded sprayers.

They are perhaps the best option for attaching some auto height-control systems, as this allows the boom wings to adjust without the centre trying to compensate. Auto boom height can help to maintain nozzle height because there is no compensating movement in the boom centre when the individual boom wings are raised or lowered automatically.

Self-levelling or pivoting boom centres

Self-levelling or pivoting boom centres are generally better suited to wider booms and for machines with less compensation in the suspension. There are several designs available that allow the centre section of the boom to pivot, which allows the boom to remain horizontal (to follow the horizon) as the chassis moves over uneven surfaces.

Tip

If the sprayer has a well set-up pivoting boom centre the boom will want to follow the horizon (due to gravity), so it is very important that there is some way of locking up the boom centre while spraying sloping country and releasing the locking mechanism when spraying reasonably level country.

Pendulum boom centres

Pendulum boom centres have one pivot point in the middle of the boom centre. The pendulum boom centre reduces the impact on the boom wings when tyres are going over uneven surfaces or holes.

Pendulum boom centre on a Jetstream® sprayer

Boom-stability-pendulum-booms

8 January 2025Boom Stability - pendulum booms. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: I just want to show you an example here of a pendulum boom. John Deer choose to have a pendulum boom. So they carry the whole boom on this center point here, and the other thing John Deere have chosen to do is bring this point down as low as possible to the nozzle. That reduces the possibility of the boom going sideways if the sprayer moves. The positive of that is, if the tyres go down a hole or a bit of a bump or whatever, it has less impact on the booms wings. The negative to this is we've got to have a system that firms up the center section if the automatic boom height raises a boom or you manually raise it. Otherwise it's a very positive system to have a pendulum boom.

Pendulum boom centres are common on some trailing sprayers and some models of self-propelled sprayers.

High pivot points on pendulum boom centres may cause the boom to move sideways when a tyre goes over an uneven surface or down a hole. This sideways shift may create issues in certain situations, such as nozzle alignment over row crops, or maintaining the position of shielded sprayers or target-selectable units, or in controlled-traffic systems. Having a low pivot point may be an advantage, as there will be less influence on the boom and less sideways movement.

Sensor-based auto boom-height-control systems may not work as intended unless the boom centre can be made more rigid with the addition of boom-roll mechanisms that stabilise the centre section when the individual boom wings are raised and lowered manually or automatically.

Tip

Tilt rams may need to be longer so the boom can be adjusted below horizontal when spraying on uneven surfaces.

Trapeze boom centres

Trapeze boom centres have two level beams with four pivot points – two pivot points on the top of the boom centre and two on the boom mast. The top two pivot points are narrower than the bottom two pivot points. A trapeze boom centre reduces the immediate effect on the boom level when the tyres go over uneven surfaces.

A trapeze boom centre on a Hardi® sprayer

Auto boom height may not work as well unless the boom centre can be made more rigid (for example, with additional boom-roll mechanisms) when the individual boom wings are raised and lowered manually or automatically.

However, when they are fitted with systems that can control the height and level of the centre section, as well as auto height control on the boom (such as the Hardi®–Norac AutoTerrain system), they can maintain boom height in very challenging terrain.

Inverted trapeze boom centres

Inverted trapeze boom centres have two level beams with four pivot points – two on the top of the boom centre and two on the boom mast. The top two pivot points are wider than the bottom two pivot points.

An inverted trapeze boom centre reduces the effect on the boom when the tyres go across uneven surfaces. It also maintains the boom height when going around corners but may struggle coming back to level quick enough.

An inverted trapeze boom centre on a Goldacres sprayer

Boom-stability-inverted-trapeze

8 January 2025Boom stability - inverted trapeze. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: Another example of a boom center, this is what we call the inverted trapese. On other brands of sprayers the actual trapese strap goes that way. It helps with the suspension of the boom, disconnected from the tyre.

Auto boom height may not work as well unless the boom centre can be made more rigid when the individual boom wings are raised and lowered manually or automatically (for example, boom-roll mechanisms).

Placing additional weight, such as target-selectable sprayer sensors or shielded sprayers, on this type of boom will require the installation of heavy-duty compensation rams on the centre section to maintain stability.

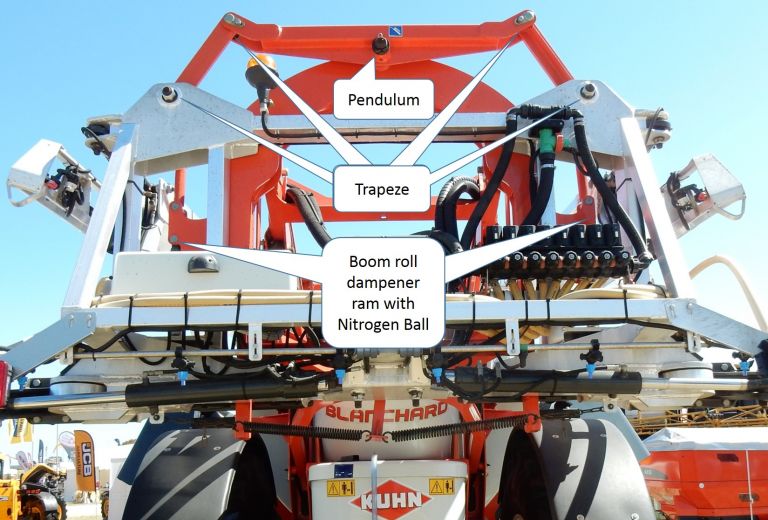

Combination pendulum/trapeze boom

Combination centres generally have four pivot points (trapeze) – two pivot points on the boom centre and two pivot points on the boom mast. The top two pivot points are narrower than the bottom two pivot points.

Boom-stability-pendulum-trapeze-boom-hardi-coil-spring

8 January 2025Boom stability - pendulum trapeze boom - hardi coil spring. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: The Hardi boom spray has what we call a pendulum trapeze boom, which is quite unique. It has a pendulum point in there, then you go to two pivot points there and the trapese on that part there. That's very unique so it gives a lot of flexibility, but it really depends on the spring system also. At the moment the coil spring is wound up too tight so if the wheel went down a hole, that would transfer that drop out onto the end of the boom. To screw them in like that you'd need to be on very level ground. When you're not on level ground these bolts need to be adjusted out to relax the spring. The coil spring there is just to return the boom back to level.

A combination of pendulum and trapeze boom centre on a Kuhn sprayer

For wider booms without auto height-control systems, this may be one of the better designs for maintaining boom stability.

As with other trapeze boom centres this centre design can reduce the impact on the boom and boom level when the tyres travel over uneven surfaces.

Auto boom height may not work as well unless the boom centre can be made more rigid when the individual boom wings are raised and lowered manually or automatically (for example, with the addition of boom-roll mechanisms).

An example of a boom centre roll dampener