Spray application manual

4 June 2025

Module 19: Shielded sprayers

19.3 Determining the applied rate for banded applications

Published 24 January 2025 | Last updated 20 January 2025

For all banded applications, including applications using shielded sprayers, the product needs to be applied within a discrete and uniform strip of a known width.

Once the required sprayed width is known the applied rate can be calculated using the same formula that is used for all sprayer calibrations:

Water rate per sprayed hectare

= litres per minute per nozzle* x 600 ÷ speed (km/h) ÷ width^ (m)

where:

* water rate per minute per nozzle (or average for more than one nozzle) applied to the band

^ the average sprayed width per nozzle to the band

Practical methods for determining the sprayed width for banded applications

The sprayed width can be determined in several ways. For a shielded sprayer this may simply be the internal width of the shield, provided the width of the spray pattern under the shield can match this width.

For individual nozzles this may be done by measuring the width of the wetted pattern on the soil or measuring the width of a single spray pattern at the target. Alternatively, the operator may use water-sensitive paper (WSP) to determine an effective sprayed width when the machine is operating in the field.

Water-sensitive paper can can be used to determined sprayed width

When using a combination of different nozzles (e.g. fan angles or orifice sizes) directed at a single plant row or into a band under a shield, use the average sprayed width and average flow rate of the nozzles to calculate the applied rate.

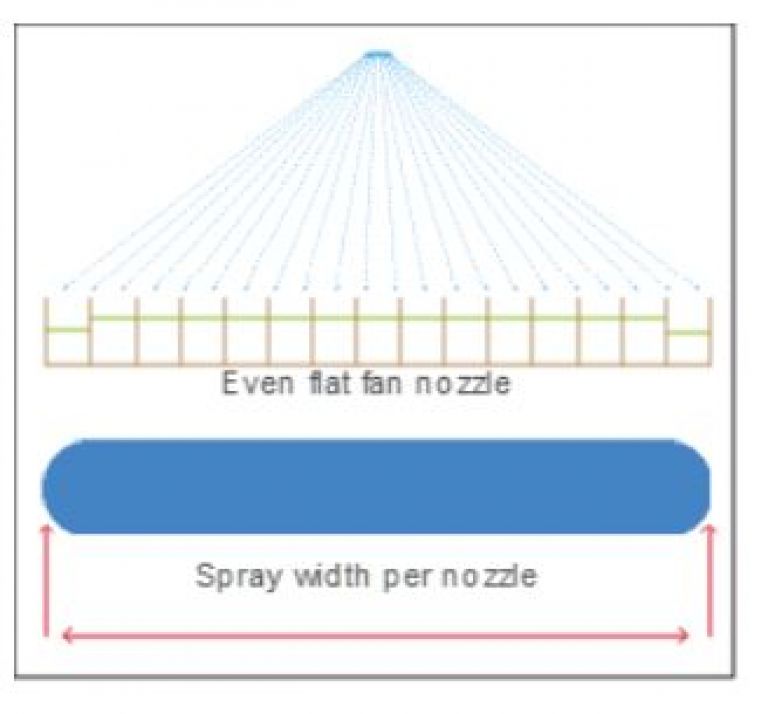

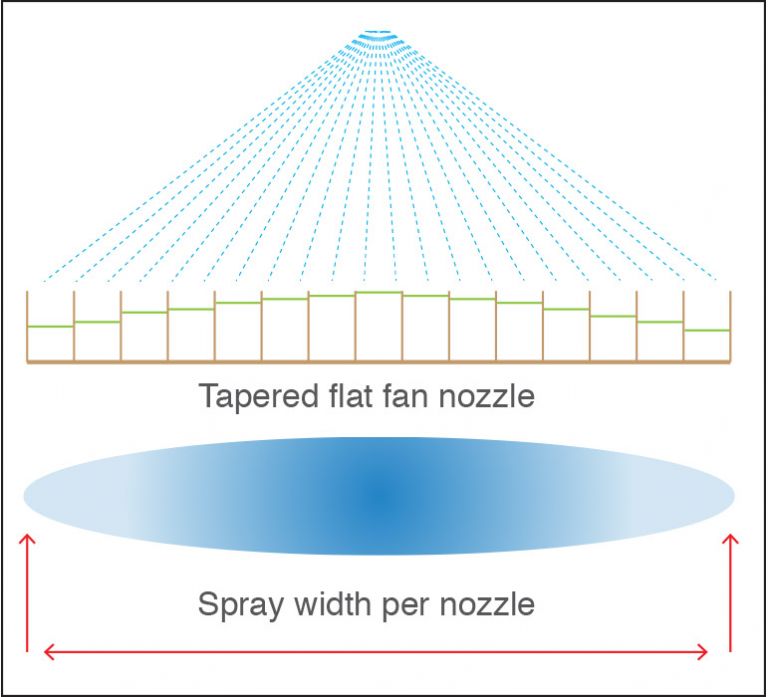

The most appropriate nozzle type for achieving a uniform band is an even flat fan

Applying a uniform band is critical to being able to achieve the same rate of product across the entire sprayed width. This is not possible when using tapered flat fan patterns (the type of nozzle spray pattern used on boom sprayers) or with solid cone nozzles (occasionally fitted to the WEEDit® target-selectable sprayer, which should only be used for spot spray rates).

Figures 1 and 2 show the difference in spray pattern (top), distribution of volume across the pattern (middle) and shape of the pattern (bottom) for a tapered flat fan and an even flat fan.

Figure 1 Tapered flat fan pattern

Figure 2 Even flat fan pattern