Spray application manual

7 June 2025

Module 19: Shielded sprayers

19.4 Nozzle choice and spray quality

Published 24 January 2025 | Last updated 20 January 2025

There are relatively few nozzle types available that can produce an even flat fan pattern compared to the range of nozzles that produce tapered flat fans. If a product needs to be applied as a coarse spray quality the range of suitable even fans becomes even smaller.

Nozzle types and fan angles available as even fans

A TeeJet® TP 80 04 even flat fan nozzle

Even flat fans

Even flat fans may be available that produce patterns at a range of angles, including 40°, 65°, 80° and 95°. However, the wider-angled even flat fan nozzles with orifice sizes up to 03 or 04 may NOT be suitable for applying many bands under shields, as the 80° and 95° even flat fans generally do not produce a coarse spray quality.

Even pre-orifice nozzles

Pre-orifice nozzles have a metering orifice to control the flow rate and an exit orifice to produce the spray pattern. Common flat fan angles available for even pre-orifice nozzles are 80° and 95°.

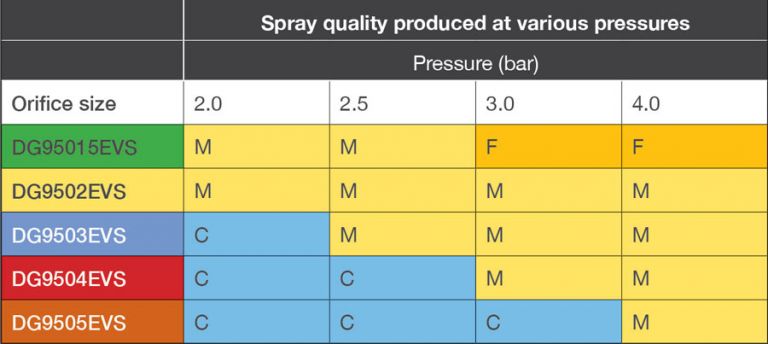

Careful attention needs to be paid to the spray quality produced at various pressures by the wider angled even nozzles as many of these begin to produce smaller droplets (finer spray quality) as the pressure is increased for the orifice sizes commonly used by applicators (see Table 1)

Many pre-orifice nozzles will have a higher minimum operating pressure compared to a flat fan, typically being required to operate at 2 bar or higher.

The even pre-orifice nozzles may be better suited to insecticide or fungicide applications over the plant row than herbicide applications under a shield in the interrow.

A TeeJet® DG 95 04 even flat fan nozzle

Spray quality data for the TeeJet DG 95° even flat fan nozzle

Even air-induction nozzles

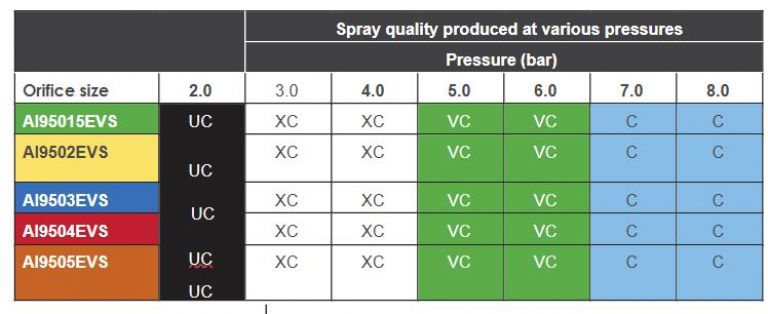

Depending on the operating pressure of the nozzle, 95-degree high-pressure air- induction nozzles that produce an even flat fan pattern are available to produce coarser spray quality (see Table 2).

High-pressure air-induction nozzles generally should be run at pressures above 4.0 bar to correctly produce the spray pattern. Some pumps and plumbing systems may not be able to operate these effectively.

A TeeJet® AI 95 04 even flat fan nozzle

Spray quality data for the TeeJet® AI 95-degree

Even twin jets

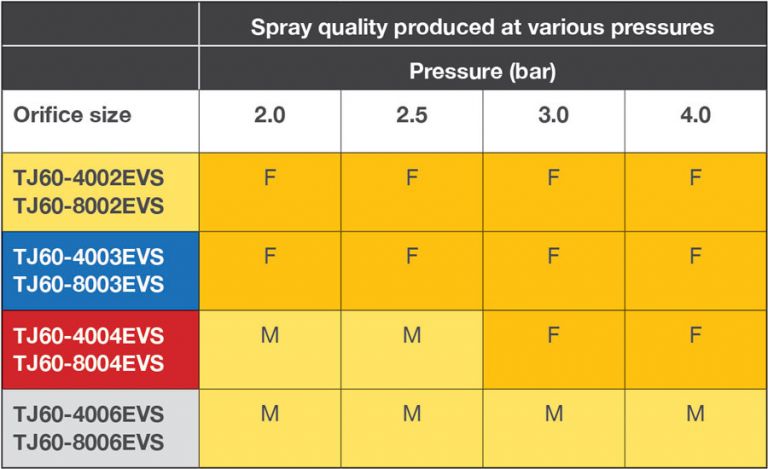

Typically, standard even twin-jet nozzles produce a fine spray quality in orifice sizes smaller than an 04 or 06. This spray quality will often not comply with many more modern herbicide labels.

One example of an even twin jet is the TeeJet® TJ60 range of nozzles. The ‘60’ refers to the angle between the two patterns, with one pattern facing 30° forwards and the other pattern facing 30° backwards. The TeeJet TJ60 even nozzles are available that produce either a 40° pattern angle or an 80° pattern angle.

A TeeJet® TJ60 even twin-jet nozzle

TeeJet TJ60-80-04EVS and smaller orifice sizes tend to produce fine spray qualities and may not be compliant with label requirements.

Be aware that standard even twin jets have two orifices that each produce half of the total volume, hence the orifice size of each outlet for the patterns is half the size of that stated for the nozzle, and the smaller orifice sizes may be prone to blockages.

The exit orifices of standard twin jets are different to the pre-orifice and air-inducted twin nozzles, where a metering orifice controls the total flow from the nozzle, and the exit orifices for the twin patterns are generally much larger than half the size of the metering orifice.

Nozzle height above the target to achieve the desired sprayed width

If the operator knows what the sprayed width per nozzle needs to be to match the band (shield width), they can use the information in Table 3 in two ways:

To determine the required distance from the target to achieve the required sprayed width (when the angle of the nozzle’s spray pattern is known).

For example, when using a 95° nozzle and a sprayed width of 0.9 metres is required to match a wide shield, Table 3 (yellow highlight) can be used to determine that a sprayed width of 0.873 metres can be achieved when the 95° nozzle is 0.4 metres above the target.

To determine the required angle of the nozzle pattern to best match the required sprayed width (If the nozzle is at a fixed distance from the target).

For example, when using a shield that is 0.9 metres wide, and the nozzle height is fixed at 0.6 metres above the ground, using Table 4 (blue highlight) the closest match for this sprayed width would require selecting an 80° nozzle, which can spray a width of 0.888 metres wide at a height of 0.6 metres.

The sprayed width of various nozzle angles

Positioning nozzles under a shield

The position of the nozzles under the shield is important to achieve the sprayed width and for coverage of the target weeds under the shield.

It is very useful to have the nozzle mounted onto a structure that will allow the nozzle height to be adjusted when required.

An adjustable bracket with T-piece for mounting nozzles under a shield

If a single nozzle is being used under a wider shield the nozzle may be adjusted to face at an angle so that the sprayed width of the pattern matches the width of the shield.

Where a T-bar or similar mounting structure is not fitted to the shield, a standard single nozzle swivel may be useful for angling the nozzle to adjust the sprayed width of the pattern.

A single nozzle swivel for mounting nozzles

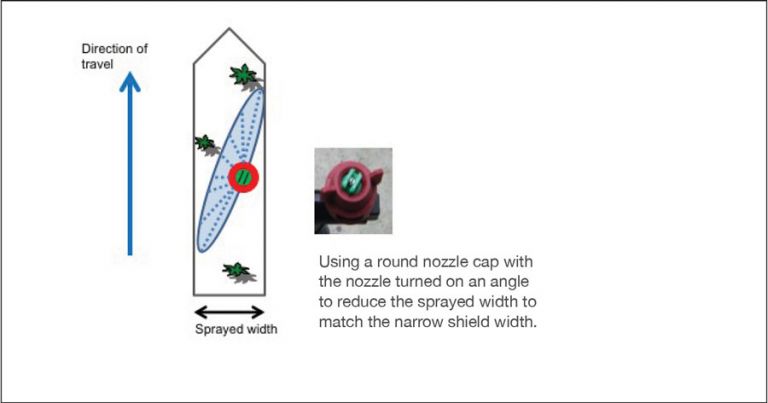

In situations where a narrow shield is being used, the angle of the even flat fan’s pattern may be too wide to have the nozzle’s pattern at a right angle to the travel direction for the shield. A solution is to have a nozzle cap with a round hole (normally used for cone nozzles), where the even flat fan nozzle can be turned within the cap to adjust the sprayed width.

A nozzle swivel for mounting nozzles

The impact of nozzle position under the shield on potential spray coverage

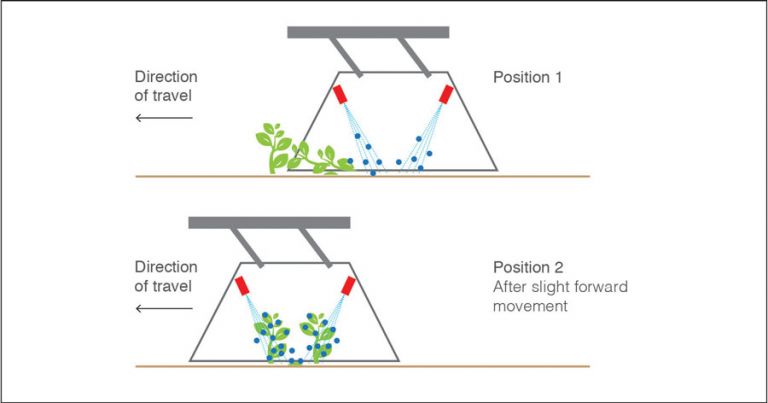

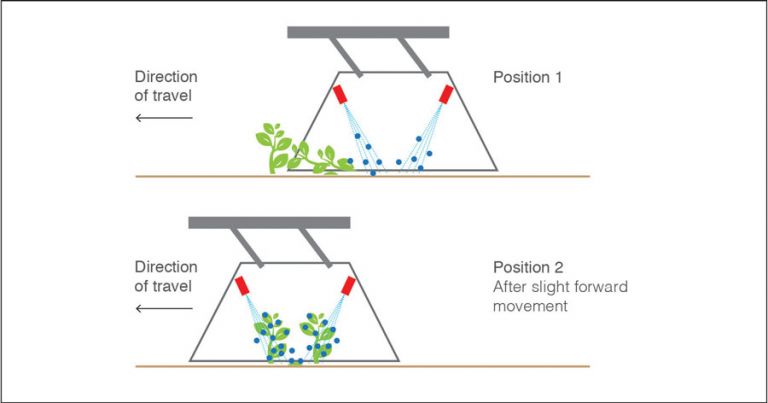

The location under the shield (in relation to the direction of travel) where the nozzle is mounted can have an impact on how much of the target weed may be covered, particularly when the weeds vary in size.

Where a range of weed sizes may be present, it is possible for larger weeds to be ‘bent over’ by the front edge of the advancing shield, which may lead to the ‘shading’ of smaller weeds. As a result, some weeds may receive less spray coverage.

The nozzle position (front, centre or rear of the shield) and the angle of the nozzle(s) under the shield can either increase or decrease the shading of smaller weeds.

Nozzle position and alignment for wider shields (more than 15 inches or 0.381 metres wide)

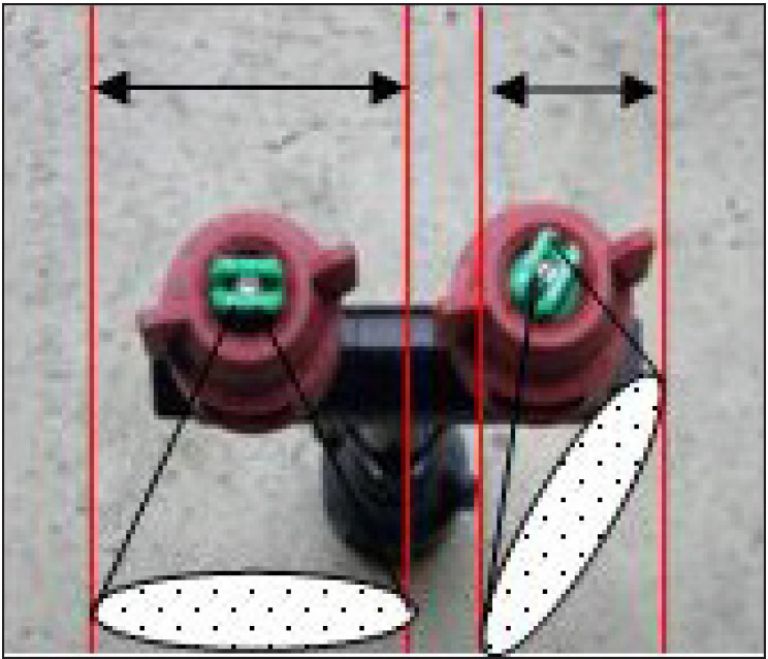

For wide shields fitted with a single nozzle, the ideal position is at the front of the shield, angled backwards. When two nozzles are able to be mounted into a wide shield, the first should be mounted at the front as described, and the other nozzle should be mounted at the rear of the shield, angled forwards, with the spray patterns of the two nozzles meeting at the ground in the centre of the shield.

A Redball shield designed for use in wider row spacings

Figures 4 to 8 show the potential impact of nozzle position and angle on weed coverage. The red ‘X’ in each diagram ( X ) indicates areas on the weed that may receive reduced coverage when a mixture of weed sizes are present and where taller weeds may ‘shade’ the smaller weeds.

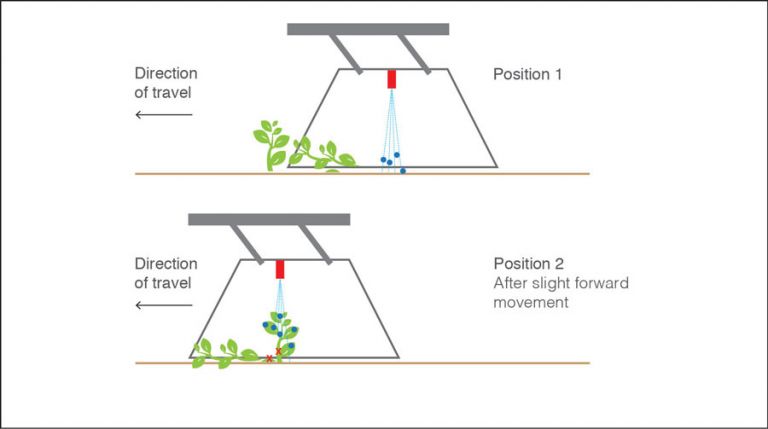

Nozzles mounted in the centre of the shield, facing downwards.

Nozzle placement in the centre of the shield is the most common set-up delivered by many shield manufacturers. In some instances this may lead to some shading in lower parts of larger weeds or shading of smaller weeds at ground level that may be directly below a larger weed.

Nozzles mounted in the centre of the shield, facing downwards.

Nozzle placement in the centre of the shield is the most common set-up delivered by many shield manufacturers. In some instances this may lead to some shading in lower parts of larger weeds or shading of smaller weeds at ground level that may be directly below a larger weed.

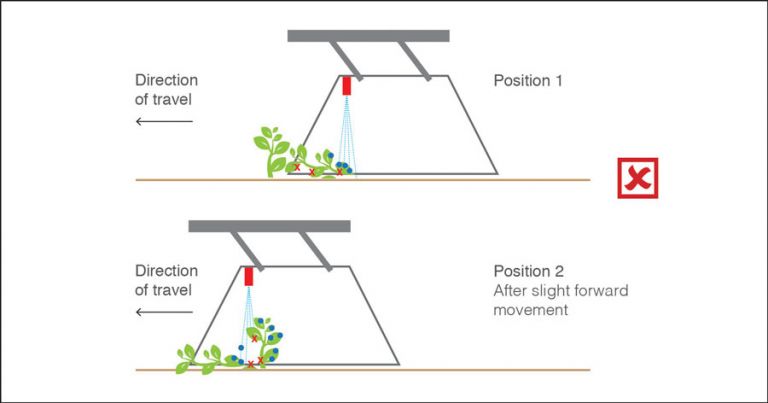

Nozzles mounted at the front of the shield, facing downwards.

Nozzles mounted at the front of the shield, facing directly downwards will result in poor coverage of larger weeds that are bent over by the advancing shield.

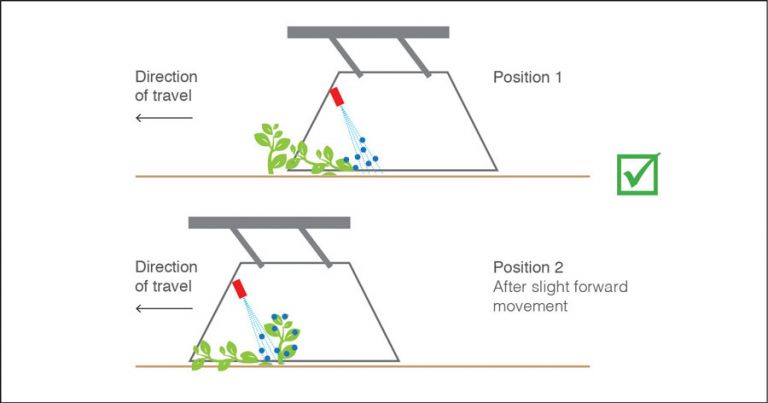

A single nozzle mounted at the front of the shield, angled backwards.

Where a single nozzle is mounted at the front under a wide shield, it should be angled backwards, which will help to overcome shading created by larger weeds.

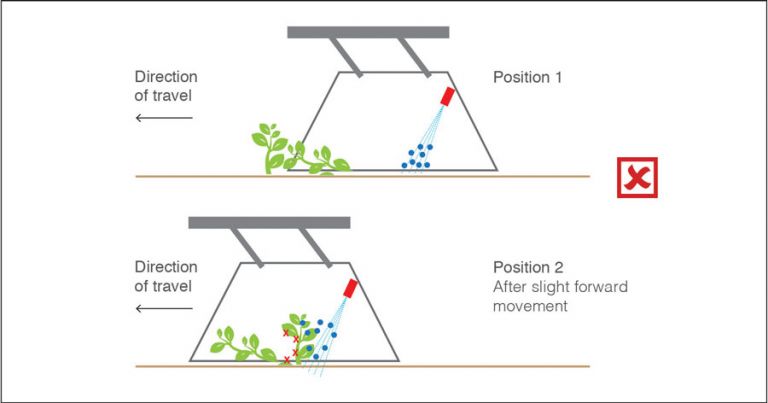

A single nozzle mounted at the rear of the shield, angled forwards.

A single nozzle mounted at the rear of the shield should not be angled forward. A single nozzle at the rear of a shield would be best directed straight down, which may still result in some shading, but would be better than having a nozzle facing straight down at the front of the shield.

Two nozzles, mounted front and rear, angled towards the centre

Where the required flow rate and spray quality can be achieved by using two nozzles, the ideal set-up would be to have them mounted at the front and rear of the shield, angled towards the ground in the centre.

A narrow row shield being used in a trial to evaluate inter-row spraying

Nozzle orientation in a narrow shield.

Where a narrow shield (about 15 inches or 0.381 metres wide or less) is to be used, the nozzle may need to be turned within a round cap to allow the pattern and sprayed width from the even fan to match the width of the shield (Figure 15).

Under narrow shields, the applied rate (litres per sprayed hectare) is likely to be quite high, due to the sprayed width (the width of the shield) and the flow rate of the nozzle types and orifice sizes that are required to produce a coarse spray quality.

For narrow shields used in the inter-row of a dense crop canopy, it is important to use an efficient crop separator on the front of the shield to minimise the potential for crop foliage to pass under the shield.

The front of a Redball shield (for wider row use)

The front of a narrow row shield