Spray application manual

7 June 2025

Module 3: Nozzle design and function

3.10: Air-induction nozzles

Published 24 January 2025 | Last updated 20 January 2025

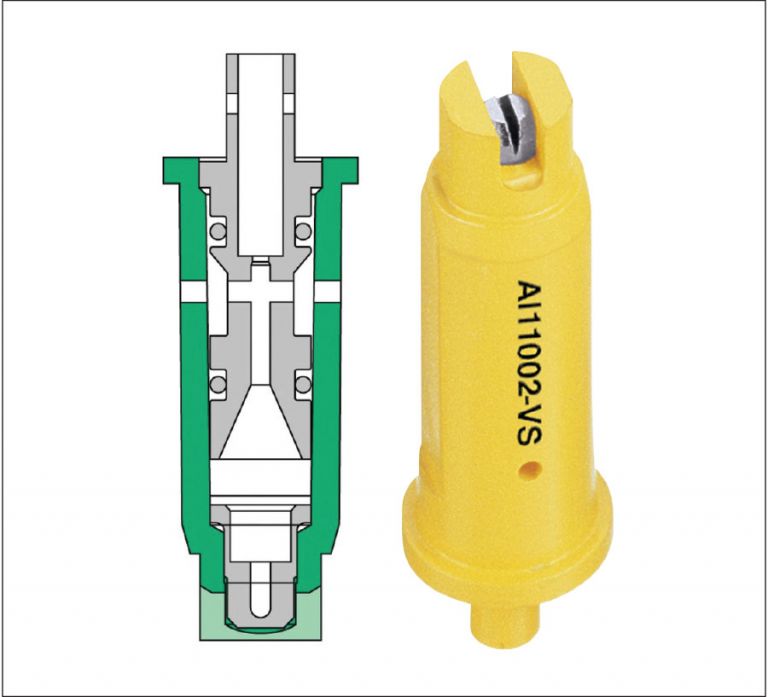

Air-induction nozzles also have a pre-orifice, but in addition to this they also have air intakes after the pre-orifice and a mixing chamber before the exit orifice.

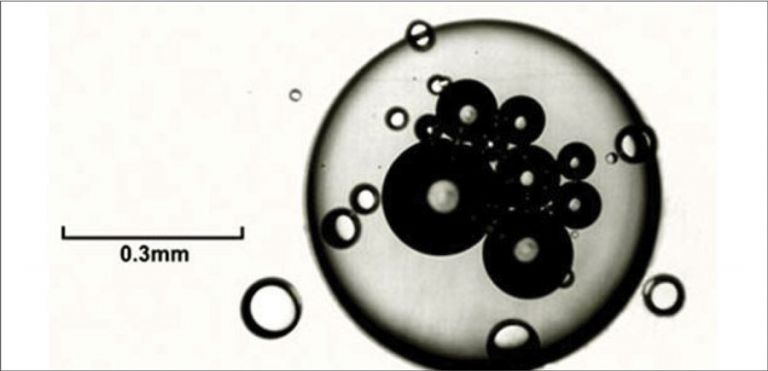

As the liquid passes through the pre-orifice a pressure drop occurs within the nozzle and air can be drawn into the nozzle by the Venturi action. Liquid and air mix, and when the sheet forms it may contain air inclusions (bubbles) that can be present in the droplets after the sheet breaks.

Air inclusions

The pressure required to efficiently operate an air-induction nozzle depends on the size of the exit orifice relative to the size of the pre-orifice. Nozzles with a large difference in size between the pre-orifice and exit orifice, and large mixing chambers, will generally require higher pressures to operate and generate the Venturi.

High-pressure air-induction nozzles

High pressure

High-pressure air-induction nozzles are generally larger in appearance, have larger mixing chambers and typically have a greater increase in size between the pre-orifice and exit orifice. High-pressure air-induction nozzles usually require a minimum pressure of 3.0 to 4.0 bar for the Venturi to work effectively.

Tip

High-pressure air-induction nozzles are designed to operate at pressures up to 8.0 bar.

Low-pressure

Low-pressure air induction nozzle

Low-pressure air-induction nozzles normally appear more compact than their high-pressure counterparts. Low-pressure air-induction nozzles tend to have smaller mixing chambers and a smaller difference in size between the pre-orifice and the exit orifice. Low- pressure air-induction nozzles usually require minimum pressures above 2.0 to 3.0 bar to get the Venturi to work effectively.

High surfactant loading and air-induction nozzles

There can be an increase in the amount of air inclusion within the droplets produced where surface tension is decreased (with the addition of wetters and spreaders) and where operating pressure is relatively high.

Increased air inclusion can lead to lower droplet density, which can result in lower sedimentation velocities and lower energy at impact. This can increase the retention of large droplets; however, in smaller droplets it may lead to greater drift potential. Smaller droplets that have high levels of air inclusion will take longer to settle to the ground compared with droplets without air inclusion (‘solid droplets’).

Conversely, the addition of some oil-based adjuvants coupled with relatively low operating pressure, may see air inclusion be reduced or completely absent from the droplets produced by an air-induction nozzle. This lack of air inclusion, combined with the effect of the oil causing the sheet to be thicker at break- up, means that the resulting droplets may be too large for some spray jobs.

Tip

If you are considering using air-induction nozzles for oil-based products (or products that require the addition of an oil-based adjuvant) try to avoid very coarse or larger spray qualities, particularly on small vertical targets. Where the label or tank-mix requires a coarse spray quality aim to operate at the lower end of the coarse spectrum (towards the medium spectrum). When targeting small grasses be aware that lower speeds could result in the minimum pressure at the nozzle causing the spray quality to become too coarse.

Summary of air-induction nozzles

Always check what you spray quality the nozzle produces at various pressures before you make a purchase.

Formulation or adjuvant may affect air inclusion in the droplets.

Check what minimum pressure is required to run the nozzle effectively on your machine, particularly with different tank mixes.

Good for applying coarse spray qualities and larger (depending on the target).

Medium droplets with high levels of air inclusion may drift more than medium droplets from some extended range or 'low drift' nozzles.

Check the spray angle - it's not uncommon for an air-induction nozzle to spray at a narrower angle than the nominated spray angle.