Spray application manual

4 June 2025

Module 3: Nozzle design and function

3.3: Properties of the droplet that affect its ability to get to the target and stay on the target

Published 24 January 2025 | Last updated 20 January 2025

Properties such as droplet size, droplet velocity, droplet trajectory and droplet density will affect a droplet’s ability to arrive at its target, be deposited and be successfully retained on that target. Different leaf surface, in particular the presence of leaf hairs (trichomes) or the type of cuticular waxes also can have a high influence on droplet adhesion.

Droplet size

Larger droplets tend to travel and sediment (settle to the ground) faster than smaller droplets, primarily due to their increased mass. Doubling a droplet’s diameter increases its mass by a factor of eight.

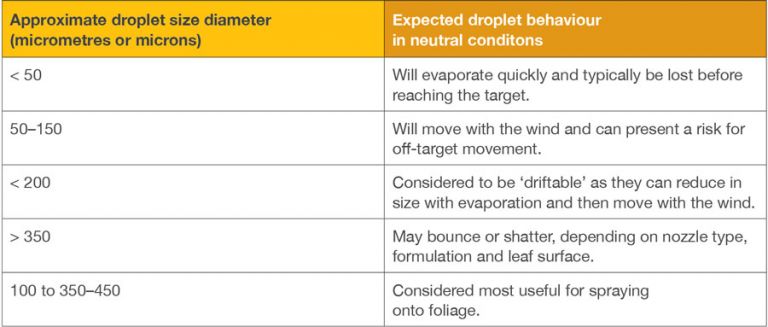

Behaviour of water-based droplets

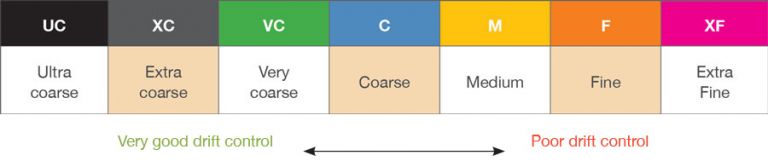

Spray quality classifications

Spray quality is classified according to the range of droplet sizes produced by a nozzle at a given pressure when compared to a set of standard reference nozzles. The Australian Pesticides and Veterinary Medicines Authority (APVMA) recognises three classification systems for determining spray quality on product labels: the American Society of Agricultural Engineers (ASAE) standard S572, International Standards Organisation ISO25358 or the British Crop Protection Council (BCPC) standard. Nozzle outputs for these are tested using water.

Spray quality and droplet size

Nozzles are assigned a spray quality classification (Table 3) by comparing their output (range of droplet sizes) at a given pressure to the output of standard reference nozzles.

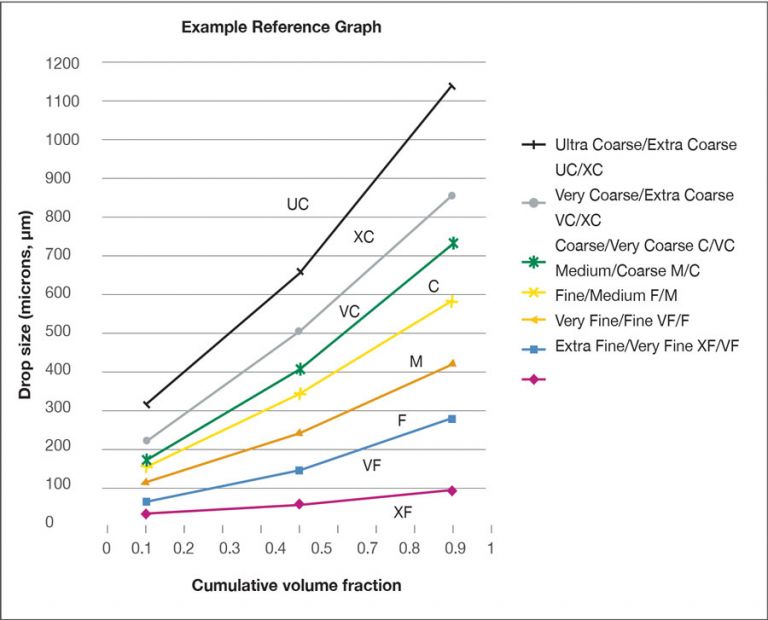

Graph 1 shows the average output of the standard reference nozzles as measured by several laser instruments, as an example of how nozzles are assigned a spray quality classification. The actual measurements would be performed through a single instrument, hence actual droplet sizes produced by a nozzle may differ from this graph.

Notes

0.1 as a cumulative volume fraction is equal to 10 per cent.

Reference graph

The cumulative volume fraction (CVF) is the percentage of a spray volume that exists as droplets less than a given droplet size (microns) (see Figure 1).

For example, if we consider 0.5 CVF for the line separating coarse and very coarse (C–VC) it is about 350 microns. Therefore, half of the spray volume would exist as droplets less than 350 microns and half would be greater in diameter than 350 microns. The 0.1 CVF for the C–VC cut-off is about 140 microns; this means about 10 per cent of the volume would exist as droplets less than 140 microns.

As a general rule, each time you move to a coarser spray quality, you approximately halve the fraction of the spray that exists as droplets less than 150–200 microns in diameter (the fraction considered ‘driftable’).

Find out more

For more information on using water-sensitive paper to look at spray coverage go to Module 21: Assessing spray deposits.

A fine spray quality could have between 40 and 50 per cent of its volume existing as droplets less than 150 microns, a medium spray quality about 20 per cent and a coarse spray quality less than 10 per cent of its volume existing as droplets less than 150 microns.

All nozzles produce a range of droplet sizes. For example, if a nozzle operating at a particular pressure is rated as 'Coarse' this does not mean that all the droplets produced will be within the coarse droplet size (which is generally accepted to be around 280-350 micron).

Typically, a 'Coarse' nozzle is likely to produce approximately 10-20% of the spray volume in droplets below 150 to 200 micron (those susceptible to spray drift). While in excess of 30% of the spray volume is likely to be in droplets over 400 micron in diameter which become increasingly difficult to retain on some leaf surfaces. These larger droplets are more likely to bounce or shatter on impact with the treated surface.

Moving to a coarser spray quality reduces the percentage of the spray volume subject to drift, however will increase the percentage of spray volume in a droplet size that is more difficult to retain on many leaf surfaces.

For coverage sensitive pesticides (contact herbicides, fungicides, most insecticides) a medium or medium-coarse spray quality is likely to provide best results. However these nozzle selections come with increasing risk of off-target spray losses.

Coarse to Very Coarse may be appropriate for pre-emergent herbicides and systemic, well translocated herbicides (note: all 2,4-D applications must be applied with a minimum of VC spray quality). These larger droplets will reduce (but not eliminate) drift risk and may have better droplet survival under summer application conditions. The downside is that these large droplets will be difficult to retain on leaf surfaces (especially upright targets like small grass weeds). Increasing spray volume with coarser spray quality is likely to be required to ensure enough of the ideal size of droplets are produced to ensure adequate coverage.

While very good for drift reduction, Extremely Coarse or Ultra Coarse droplets are generally only able to be used with fully systemic, well translocated herbicides and are only recommended for situations where a sensitive area is downwind of the release site. Where used, water rates should be increased, typically to over 100 L/ha - especially when targeting small, upright grass weeds.

Impact of spray quality on the number of droplets produced and spray coverage

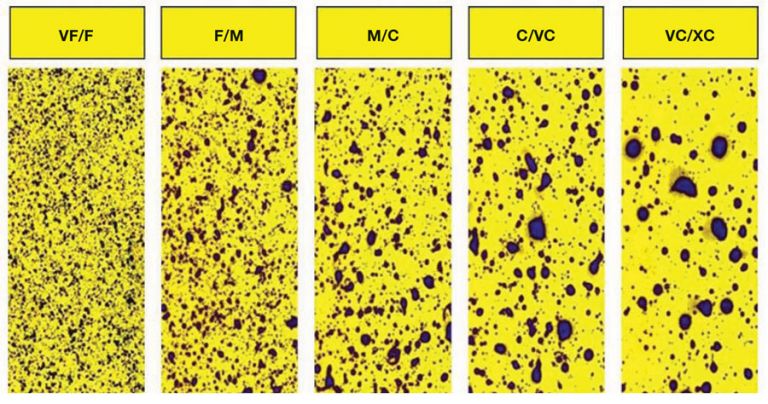

The number of droplets produced per litre of spray decreases as spray quality becomes coarser. You can see this by depositing droplets onto water-sensitive paper using an equivalent application volume and nozzles representing the cut-off of each spray quality classification.

Water-sensitive paper