Spray application manual

4 June 2025

Module 3: Nozzle design and function

3.2: Nozzle design and function

Published 24 January 2025 | Last updated 20 January 2025

The primary function of a nozzle is to control flow rate and convert the spray liquid into droplets (via atomisation) that are of a suitable size for depositing on the intended target.

Flow rate is influenced by the orifice size, operating pressure at the nozzle and, to an extent, by the specific gravity and viscosity of the spray solution (see Module 8: Calibration of the spray system).

Spray quality (the size of the droplets produced) is influenced by nozzle design, operating pressure, the angle of the spray pattern, the properties of the tank mix (including adjuvants in the formulations and/or added to the tank mix) and (for some nozzles) the inclusion of air into the droplet.

To consider how all of these factors may interact to influence the results of a spray application we will discuss some properties of droplets that can affect their deposition and retention at the target.

Once these properties have been discussed, we will focus on how variations in nozzle design and operating parameters can impact on this process.

Find out more

Nozzle flow rates

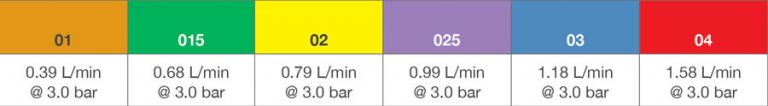

The flow rate of ISO (International Organization for Standardization) nozzles is based on US gallons. A 01 orifice produces 0.1 US gallons per minute at 40 PSI (pressure per square inch) (with water), which is equivalent to 0.39 litres per minute at 3.0 bar.

Nozzle flow rates

The flow rate of each nozzle size is a multiple of the flow rate of 01 at the same pressure. For example, a 03 has three times the flow rate of a 01 at the same pressure.