Spray application manual

5 June 2025

Module 3: Nozzle design and function

3.8: Standard or extended range flat fans

Published 24 January 2025 | Last updated 20 January 2025

Nozzles

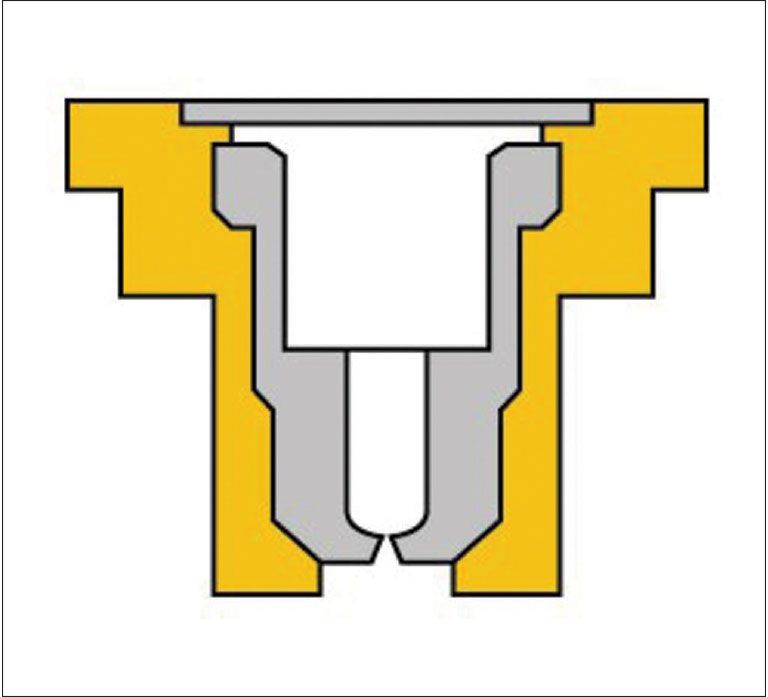

Standard flat fans or extended range flat- fan nozzles contain a single orifice that controls flow rate and determines the spray pattern.

As the spray solution leaves the orifice it forms a sheet. Droplets are formed when that sheet becomes unstable and breaks apart. Several things affect how the sheet is formed and how and when it begins to break up.

Sheet break up

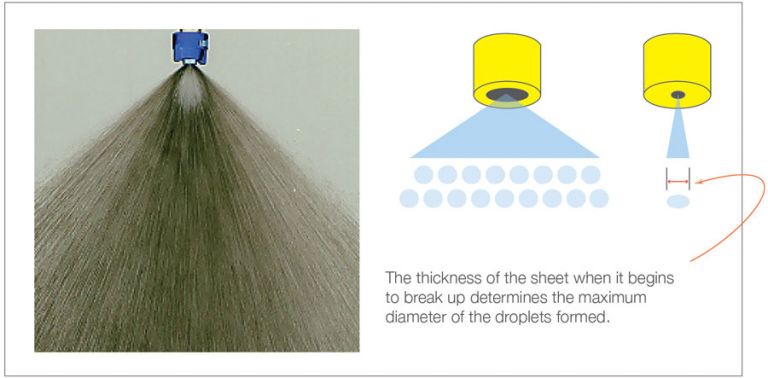

Thickness of the sheet at break-up influences droplet size

The thickness of the sheet helps to determine the size (diameter) of the droplets produced. The thicker the sheet is when it begins to break up, the larger the diameter of the droplets produced.

Orifice size and shape (angle of the pattern)

At equivalent pressures, single orifice nozzles, such as the standard and extended range flat-fan nozzles, with larger orifice sizes tend to produce thicker sheets, which result in larger droplets than the same nozzle type with smaller orifice sizes.

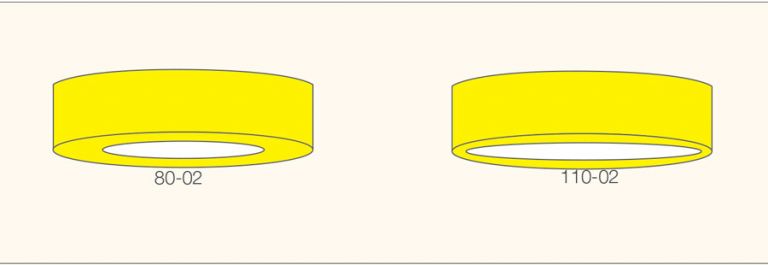

The shape of the orifice or fan angle can affect droplet size. Compare two extended range flat-fan nozzles with the same orifice size (02) and therefore the same output rate (L/min) (figure 3). At the same operating pressure, one produces an 80-degree pattern and the other produces a 110-degree pattern. The difference orifice shape with these nozzles produces different fan angles despite both applying the same volume – the 110-degree nozzle will have a longer and thinner shaped orifice than the 80-degree nozzle.

At equivalent pressures, a 110-degree nozzle will typically produce a thinner sheet and smaller droplets than an 80-degree nozzle.

Orifice shapes

There are additional things to consider if you are using a narrower fan angle

Narrower fan angles tend to increase droplet velocity. This means that the droplets can impact on the target at higher speed. This can affect droplet retention (better for small droplets, but possibly worse for large droplets). Conversely, for pre-emergent herbicide application where the desire is to reach the soil and have less risk of capture onto stubble and weeds, then a narrower fan angle and faster droplet velocity is likely to be beneficial.

Narrower fan angles are better suited to narrower nozzle spacing or where increased release height is utilised..

Narrower fan angles tend to become blocked less than wider fan angles due to the shape of the exit orifice.

Narrower fan angles tend to allow more air movement between spray patterns across the boom, which can reduce the escape of small droplets (detrainment) from the spray pattern. This has the potential to reduce spray drift.

With many high-clearance and self-propelled boom sprays, it may not be possible to lower the boom height enough to be able to achieve the desired double-overlap position when using nozzles with wide fan angles e.g. a 110 degree nozzle on 50cm boom spacing requires the boom to be approximately 40-50cm above the target to achieve double-overlap. Running wide angled nozzles at heights above the double-overlap position does not improve coverage, but does increase spray drift risk. Narrower fan angles typically deliver an improved outcome where increased boom heights must be used.

Find out more

For more information refer to Module 17 Pulse Width Modulation systems, Module 19 Shielded sprayers and Module 20 Optical spot sprayers for more information on nozzle requirements for these systems.

Impact of operating pressure on droplet size

When pressure at the nozzle is reduced, the angle of the spray pattern tends to collapse; this normally causes the sheet to become thicker when it breaks apart and droplet size increases. For many nozzles, extremely low operating pressure can result in the sheet completely collapsing and the range of droplet sizes produced becomes uncontrolled. Typically it is best to run nozzles towards the middle to upper end of their operating pressure range.

As the pressure at the nozzle is increased, the fan pattern tends to open up and the angle of the spray pattern widens; this causes the sheet to become thinner when it breaks and droplet size to become smaller. For many nozzles this is particularly noticeable on the edges of the sheet.

Summary of standard or extended range flat-fan nozzles

Increased pressure reduces droplet size

Wider fan angles reduce droplet size

Reducing surface tension (through surfactants) reduces droplet size

Smaller orifice sizes reduce droplet size

Droplet velocity is relatively high – there is potential for poor retention of large droplets

Best for fine to medium spray qualities.