Spray application manual

4 June 2025

Module 3: Nozzle design and function

3.9: Variations on the standard flat-fan nozzle design

Published 24 January 2025 | Last updated 20 January 2025

Pre-orifice nozzles

Many pre-orifice nozzles (often referred to as ‘low drift’ nozzles) look similar to standard flat fans, but can be identified by a plug or a plate near the inlet of the nozzle.

As the name suggests these nozzles have a pre-orifice as well as an exit orifice.

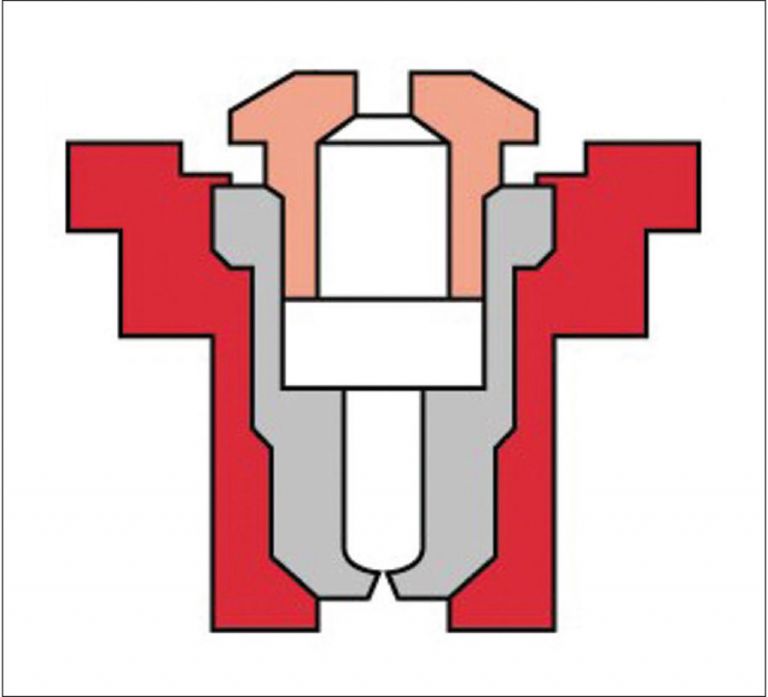

Cross-section of a pre-orifice nozzle

Pre-orifice nozzles contain a metering orifice close to the inlet that is used to control flow rate. The exit orifice is used to create the spray pattern.

The exit orifice is usually larger than the metering orifice. This creates a pressure drop within the nozzle so the pressure at the exit of the nozzle will be lower than that in the spray line or at the inlet of the pre-orifice.

The combination of the internal pressure drop and the larger size of the exit orifice cause the sheet to be thicker than equivalently sized standard or extended range flat fans.

Droplet sizes produced by pre-orifice nozzles tend to be larger than standard or extended range flat fans and have lower exit velocities when operated at the same pressure.

A comparison of spray quality classifications

Pre-orifice nozzles such as the DG tend to larger droplets than equivalent sizes XR nozzles.

Larger droplets with lower velocities from a pre-orifice nozzle may have improved retention on the surface target than those of a standard or extended range flat-fan nozzle, which may be traveling at faster velocity.

The internal pressure drop within pre-orifice nozzles means they will generally have a higher minimum pressure requirement than equivalently sized standard flat-fan nozzles. This can have implications for the practical range of application volumes or range of travel speeds that pre-orifice nozzles can be used at compared to extended range flat-fan nozzles. That is unless the pre-orifice nozzle has an equivalent range of flow rates at its operating pressure range.

Pre-orifice nozzles are usually more difficult to block than equivalently sized standard or extended range flat-fan nozzles as the metering orifice is usually round rather than tapered and the exit orifice is normally larger. The only exception may be some pre- orifice nozzles that have more than one metering device or inlet (where each one may be quite small in diameter).

Pre-orifice summary

Good for medium to coarse spray qualities due to the improved retention of slower droplets compared to standard or extended flat-fan nozzles.

Potentially less blockages than standard or extended flat-fan nozzles of the same size and angle.

Higher minimum pressure may reduce speed or volume range compared to extended flat fan nozzles.