Spray application manual

15 March 2025

Module 3: Nozzle design and function

3.11: Anvil and hybrid anvil nozzles

Published 24 January 2025 | Last updated 20 January 2025

Anvil nozzles use a deflector or plate rather than an exit orifice to produce a spray pattern.

There are several variations of this nozzle type.

Anvil nozzles use a pre-orifice to control the flow rate and deflectors and make the spray pattern. Examples of anvil nozzles include TeeJet®’s Turbo FloodJet®, Turbo TeeJet® (TT), and Turbo TwinJet (TTJ60).

Cross-section of a twin-jet

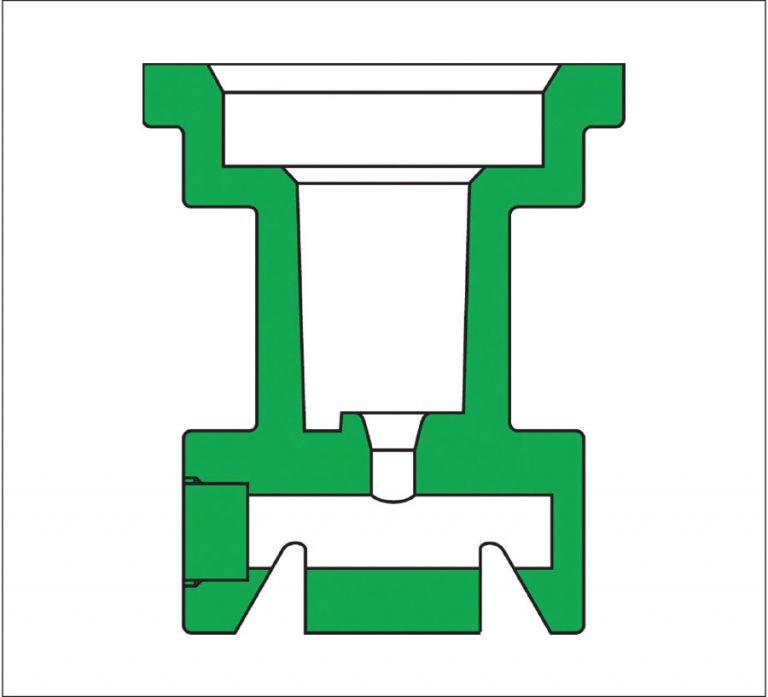

There are also hybrid anvil nozzles that include air-induction, such as the Turbo TeeJet® Induction (TTI) and the Air- induction Turbo TwinJet (AITTJ60) that draw air into the nozzle by Venturi.

A hybrid air-induction Turbo TeeJet

Other hybrid versions have air forced into them via a compressor, such as the nozzles fitted to several twin-fluid sprayers, including Airtec, Agrifac, Optispray® and Airmatic.

Key differences between anvil nozzles and orifice nozzles

Anvil nozzles tend to produce wider fan angles than standard flat-fan nozzles.

Pre-orifice versions tend to have lower droplet velocities than equivalently sized standard flat fans. Spray quality at a given pressure appears to be less affected by changes in formulation than nozzles that use an exit orifice to produce the spray pattern.

The pre-orifice versions tend to reduce droplet size quite rapidly as the pressure to the nozzle is increased, so they usually have a lower range of operating pressures to maintain the desired spray quality. This makes them quite useful for manual pressure systems, but can be limiting when running an automatic rate controller.

The hybrid air-inducted versions tend to produce very large droplets over their entire pressure range.

Tips

Most anvil nozzles have an offset pattern. Rather than directing the pattern towards the ground, the pattern is typically offset by 10 to 15 degrees from the vertical. If using anvil nozzles to apply medium or fine spray qualities, align the nozzles on the boom so that the offset patterns are facing in the same direction as the direction you are travelling. Forward-facing pattern alignments result in more spray arriving at the target and less spray remaining airborne compared with backward-facing pattern alignments.

Conversely, if using offset nozzles to apply large droplets (i.e. VC spray quality and above) then it may be beneficial to orientate the nozzle backwards to counteract forward momentum from the boom and the shading that this can cause when traveling at ground speeds above around 18 kph. However, do not operate with rear facing nozzles when using medium or smaller droplets, as this will drastically increase spray drift risk.