Spray application manual

5 June 2025

Module 11: Pumps, plumbing and components

11.1: Introduction

Published 24 January 2025 | Last updated 20 January 2025

For spraying, the principle of using a pump to transfer liquid from the spray tank to the nozzles remains the same as it has for decades, but the options available to control the flow to the boom and the output from the nozzles has advanced enormously in recent years.

Plumbing has become increasingly important as spray application equipment has increased in size and complexity. There are many options available, so the operator must ensure that the plumbing and components chosen are suitable for the task and correctly installed to allow the sprayer to perform as intended.

There are entire books written about sprayer pumps and components so the aim of this module is not to ‘reinvent the wheel’, but to provide information and tips on how the components can best work together, along with how to best install them into the spraying system to ensure it continues to operate efficiently and effectively.

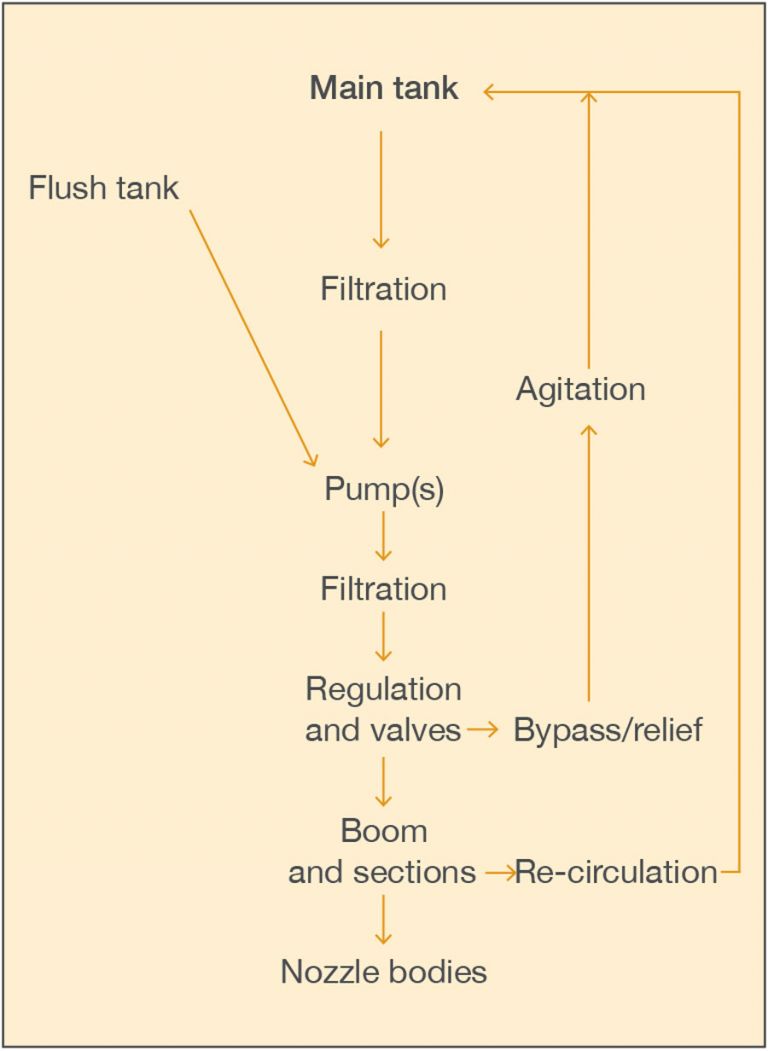

The major components of the spraying system and considerations discussed in this module are outlined in Figure 1.

Plumbing systems

Things for the operator to consider

Main tank: shape, sumps, isolation

Flush tank: size relative to main tank

Filtration: suction, pressure, section, nozzles

Pumps: diaphragm or centrifugal

Regulation: pressure relief, bypass,

Agitation: sparge, venturi

Valves: two way, three way

Re-circulation: manual or electric

Nozzle bodies: wet boom, dry boom