Spray application manual

7 June 2025

Module 11: Pumps, plumbing and components

11.17: Examples of common plumbing configurations and tips

Published 24 January 2025 | Last updated 20 January 2025

Unfortunately, many of the ways that sprayers get plumbed do not allow all of the components to work as they were intended.

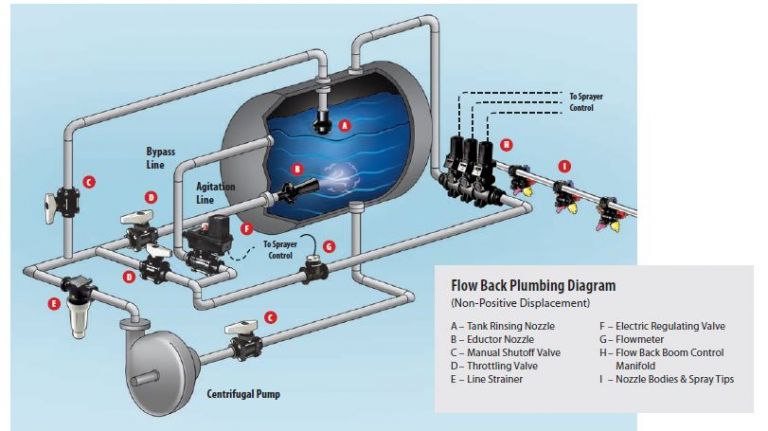

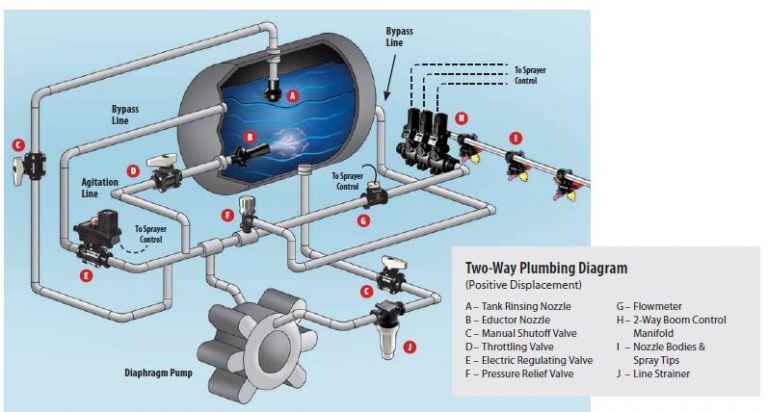

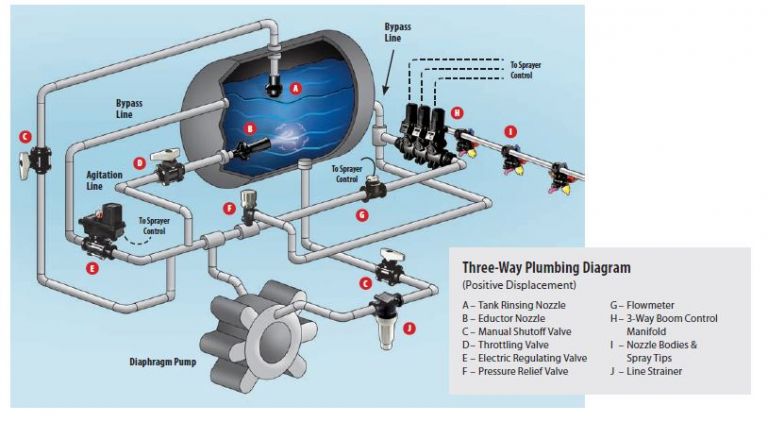

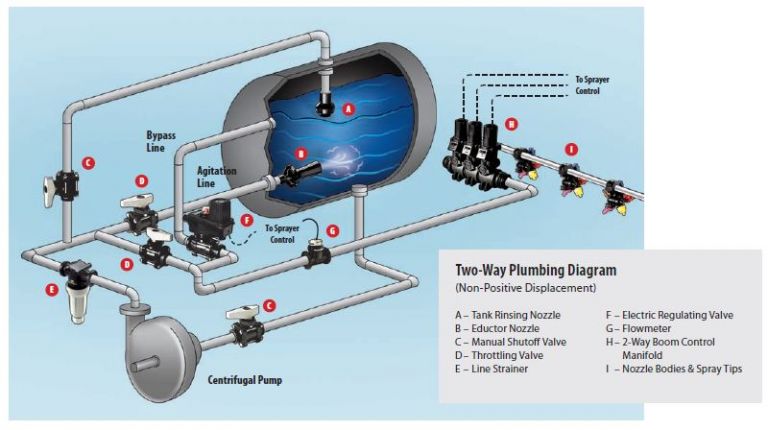

Figures 1, 2, 3 and 4 provide examples of how different pump types and valve configurations can be plumbed to ensure each component works efficiently.

Figure 1 provides an example of a positive-displacement (diaphragm) pump plumbing set-up with two-way boom valves.

Figure 2 provides an example of plumbing a positive-displacement (diaphragm) pump set-up with three-way boom valves.

Figure 3 provides an example of a centrifugal pump set-up with two-way boom valves.

Figure 4 provides an example of a centrifugal pump set-up with three-way boom valves.

Example of a positive displacement (diaphragm) pump plumbing set-up with two-way boom valves

Example of plumbing a positive-displacement (diaphragm) pump set-up with three-way boom valves.

Example of a centrifugal pump set-up with two-way boom valves.

Example of a centrifugal pump set-up with three-way boom valves.