Spray application manual

7 June 2025

Module 11: Pumps, plumbing and components

11.8: Flow meters

Published 24 January 2025 | Last updated 20 January 2025

There are two types of flow meters commonly used on sprayers: impeller flow meters and electromagnetic flow meters.

Impeller flow meters come in a range of sizes and flow capacities

Impeller flow meters

Impeller flow meters have traditionally been the most common flow meters used on sprayers.

As the name suggests, they use an impeller, located in the meter housing, which is mounted on a shaft. As liquid passes over the impeller it rotates and signals or pulses (based on the number of revolutions) are sent to the rate controller to indicate the flow rate of the liquid.

Impeller flow meters will have a calibration factor or figure that may need to be changed to take into account possible changes in the density or viscosity of the product being used.

To maintain their accuracy, impeller-type flow meters need to be serviced regularly by cleaning the impeller and removing any build-up of product, and checking for possible wear of the bearings.

Find out more

For more information on calibrating flow meters, go to Module 8: Calibration of the spray system.

Electromagnetic flow meters

Electromagnetic flow meters rely on a pulse and have no moving parts. They are less likely to be impacted by the density or viscosity of the spray solution. They are becoming more common on sprayers as operators increase the use of liquid fertilisers and other spray solutions with higher densities.

For the best results when using an electromagnetic flow meter, they should be mounted into the spray line so that the flow meter is orientated vertically (flow coming in the bottom and out the top), ensuring that the sensor is facing sideways (sending pulses horizontally through the liquid).

Mounting the flow meter this way reduces the likelihood that air or turbulence in the spray line will impact on the accuracy of the reading.

Plumbing mounting of flow meters

7 January 2025Plumbing - mounting of flow metres on spray rigs. Another video from GRDC's Spray Application GROWNOTES™ series.

Graham Betts: It's ideal to mount the flowmeter in a vertical position, and it's also very important to have a reasonably straight piece of house going up to the flowmeter. Roughly 10 times the diameter of the entry point in length, and there's two good reasons for that: One is that if there's any residue left there it'll come down to the bottom of the hose, and another reason is if there's any air in the system, when the water or liquid comes up in a column there there's less likelihood of the air influencing the flow meter reading.

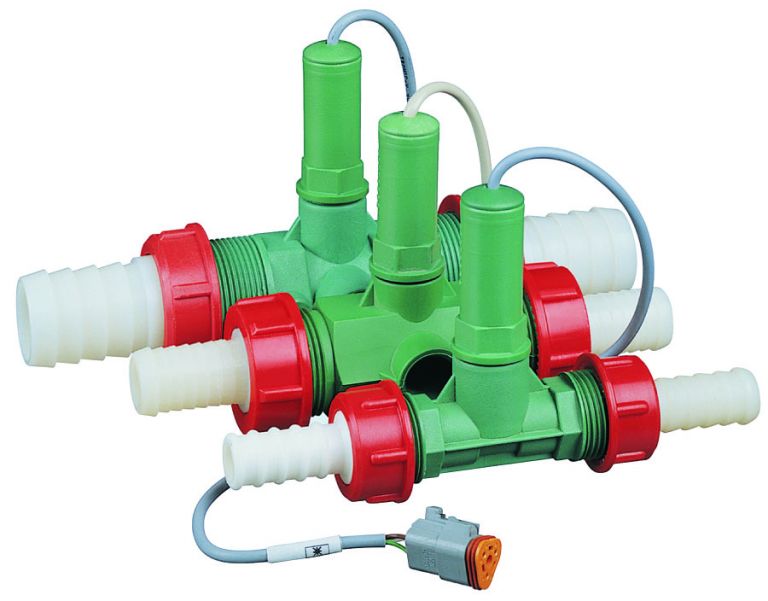

ARAG® electromagnetic flow meter mounted vertically

Consider the lower limit of flow that each flow meter can detect

Most flow meters will have a lower limit of flow that they can detect, which will be stated in the product literature.

If the flow rate through the flow meter drops below the minimum that it can detect, it will not be able to provide reliable information to the rate controller to correctly adjust the sprayer’s output.

Low flow rates through a flow meter can create a problem for many spray applicators, especially when the sprayer is fitted with narrow boom sections, or when using an individual nozzle shut-off system, where the flow rates can be particularly low at low spraying speeds. In these situations, it may be important for the sprayer to be fitted with a rate controller that can utilise both flow and pressure readings to enable it to adjust the sprayer’s output.

For example, when the flow through the flow meter drops below the minimum that the flow meter can detect, the rate controller may be able to switch to using the nozzle pressure to adjust the sprayer’s output. When the flow rate through the flow meter comes back into its operational range, the rate controller reverts back to using the measured flow to adjust the sprayer’s output.

Tips

Always recalibrate the flow meter after it has been serviced.

Ideally, impeller and electromagnetic flow meters should be mounted vertically, with the outlet at the top and the feed from the bottom, using a length of straight hose (about 10 times the size of the flow meter inlet). This will reduce the possibility of air affecting the flow reading. Mounting the flow meter vertically reduces the chance of product settling in the flow meter.

It is ideal to have a manual ball valve positioned somewhere past the flow meter (e.g. on the end of boom valve manifold) to make it easy to flush the manifold and to make it easy to calibrate the flow meter.

Mount electromagnetic flow meters so the sensor is facing horizontally.

It may be useful for the operator to complete spray plans to work out the required flow range of the flow meter.

Find out more

For more information on preparing spray plans go to Module 5: Spray plans.