Spray application manual

15 March 2025

Module 11: Pumps, plumbing and components

11.2: The main spray tank

Published 24 January 2025 | Last updated 20 January 2025

The most common materials that spray tanks are manufactured from are stainless steel, polypropylene and fibreglass (with a shiny layer of glass on the inside, no fibre showing). Of the three, stainless steel tanks will increase the sprayer’s weight, but will also tend to hold their shape (and known volume) better than the other materials.

The most important requirements of the main spray tank are that there are no internal ledges and that it is shaped so it is relatively easy to keep products agitated and in solution. The main tank should also have a tapered bottom with a main and secondary sump.

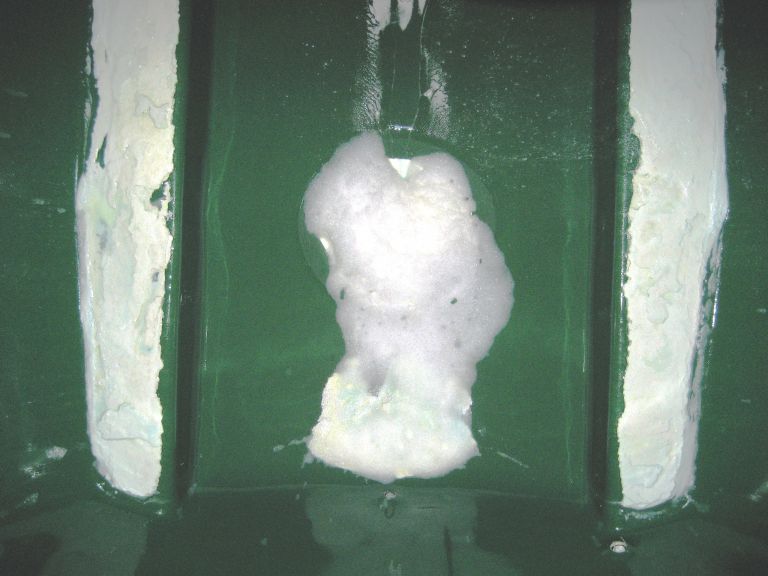

Residue on tank ledges

Main sump and secondary sump

The main sump needs to be in the lowest point of the tank, and positioned so that the sprayer frame does not prevent the installation of a tank outlet at the bottom of the sump (not at the side of the sump).

The secondary sump is the shape of the tank floor, which should taper from all corners and edges of the tank into the main sump.

There should only be one hole at the base of the tank (sump) for the outlet. An additional hole should only be installed at the end of an elongated tank if a Venturi agitator is to be fitted.

All other plumbing and return hoses to the tank, including the plumbing for sparge agitators, should be installed in the top of the tank. This will help to reduce potential problems if fittings start to leak and will allow the tank to be isolated from other components. This is particularly important if you need to complete work on the plumbing while the tank is full of water or product, and to help with troubleshooting or cleaning filter screens.

A tank outlet that does not move when installing fittings and allows the tank to be totally drained is very practical, e.g. a Banjo® Bottom Drain manifold bolted tank fitting. It is very important to have an anti-vortex fitting in any tank outlet to reduce the chance of the pump sucking air.

Tips

It is important to use a bottom drain tank outlet e.g. Banjo® Poly Bolted Bottom Drain. Tank flanges will allow the tank to be drained completely.

Install an anti-vortex fitting in the top of the tank outlet to help reduce the chance of the pump sucking air when the tank is low.

Install a manual ball valve on the tank outlet so the main spray tank can be isolated if there is a problem with the sprayer.

It is ideal to use ‘flange’ or ‘fly-nut-and-tail’ fittings to make installation, adjustment, maintenance, servicing and repairs easier. For example, removing a centrifugal pump to be repaired would be very easy if the pump inlet and outlet fittings are flange or nut-and-tail fittings. Ideally these fittings could be used at any location on the sprayer on components that may need to be serviced, adjusted or replaced.